Transverse flame glass melting furnace with flue gas waste heat recovery function and working method thereof

A flue gas waste heat, glass melting furnace technology, applied in glass production, glass furnace equipment, glass manufacturing equipment and other directions to achieve the effect of reducing floor space and construction costs, reducing heat loss and saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

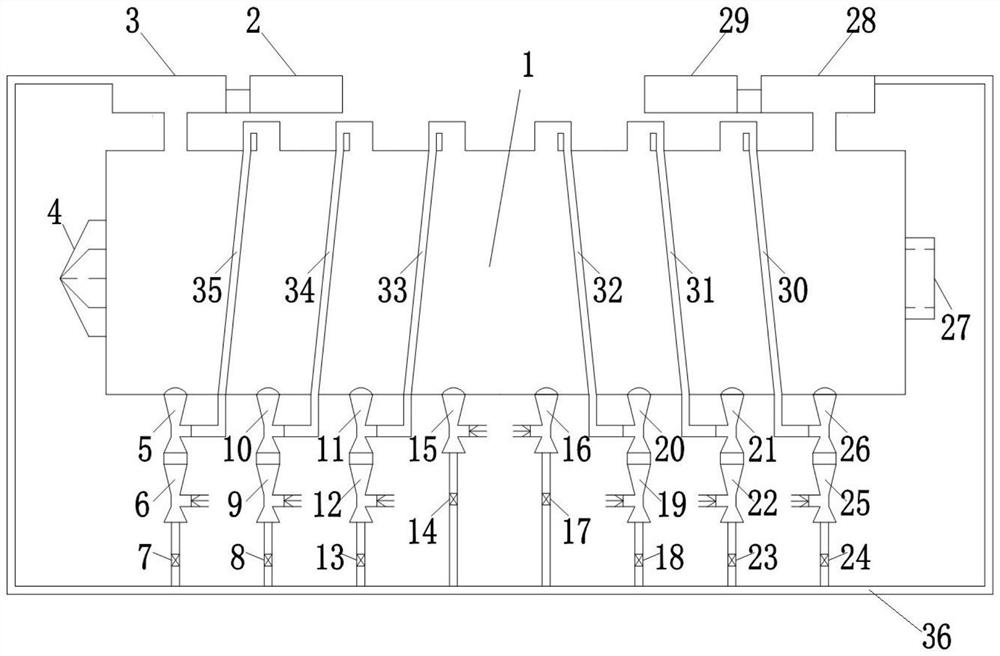

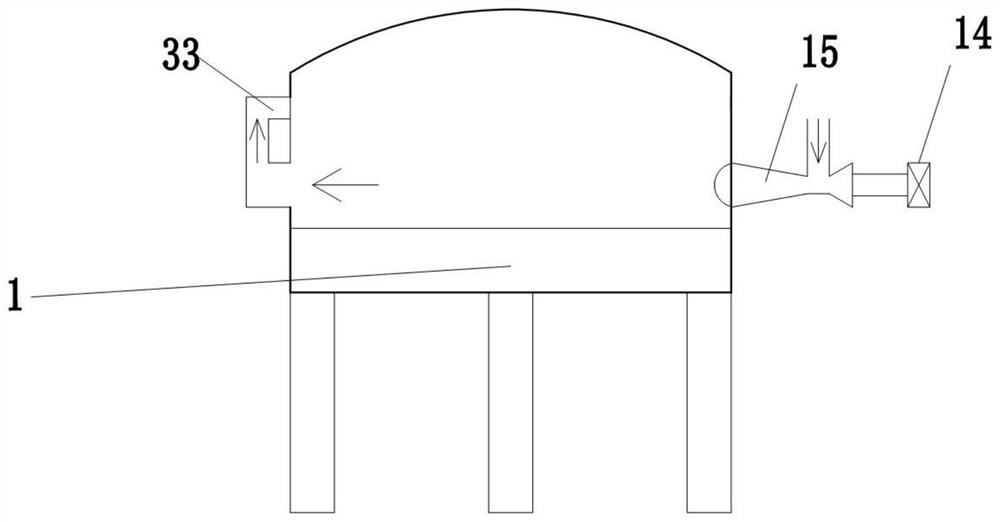

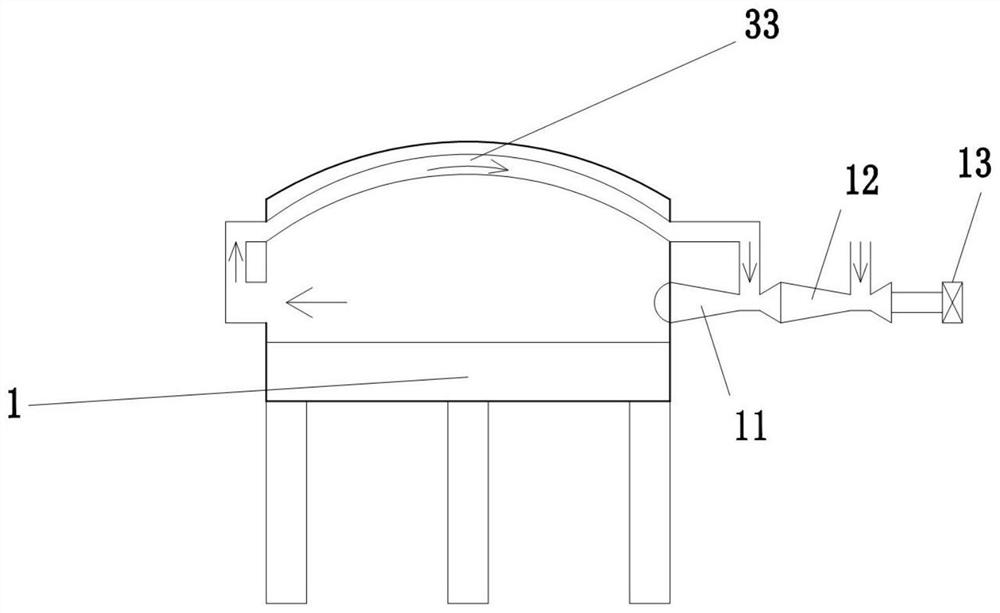

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0036] The cross-flame glass melting furnace with flue gas waste heat recovery function of the present invention includes a kiln pool 1, a partition heat exchanger, a gas-supporting source, a fuel supply system, a combustion spray gun and a jet heat pump; one end of the kiln pool 1 in the length direction is provided with The feed port 4 is provided with a liquid flow hole 27 at the other end; a number of flame nozzles are opened on the breast wall on one side of the longitudinal axis of the kiln pool 1, and a number of smoke outlets are correspondingly opened on the breast wall on the other side; the flame nozzles and the smoke outlets are They are all arranged along the horizontal axis of the kiln pool 1 from the highest level to the last level in order to both sides; the highest level flame nozzles are equipped with combustion spray guns, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com