Seat height adjustment carrying structure

A height adjustment and seat technology, which is applied to vehicle seats, movable seats, special positions of vehicles, etc., can solve problems such as scratches, abnormal noises, and plastic handles colliding with the outer large guard plate, achieving high versatility, The effect of saving the number of parts and avoiding gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

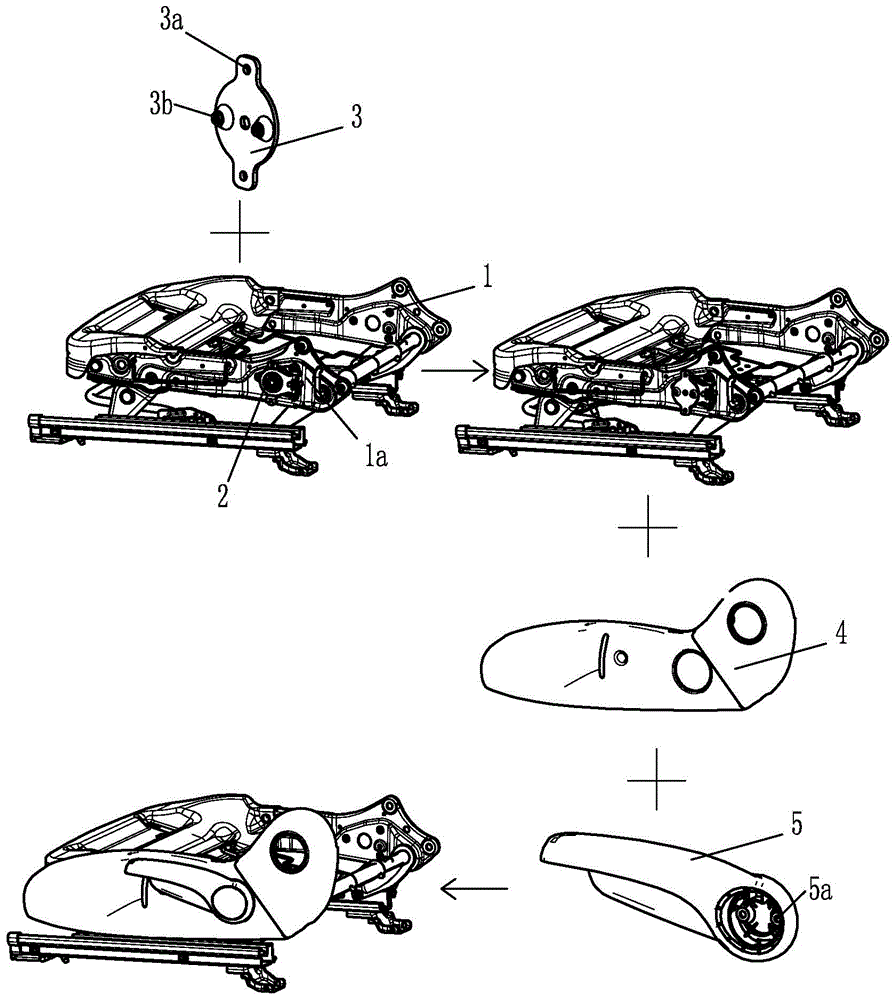

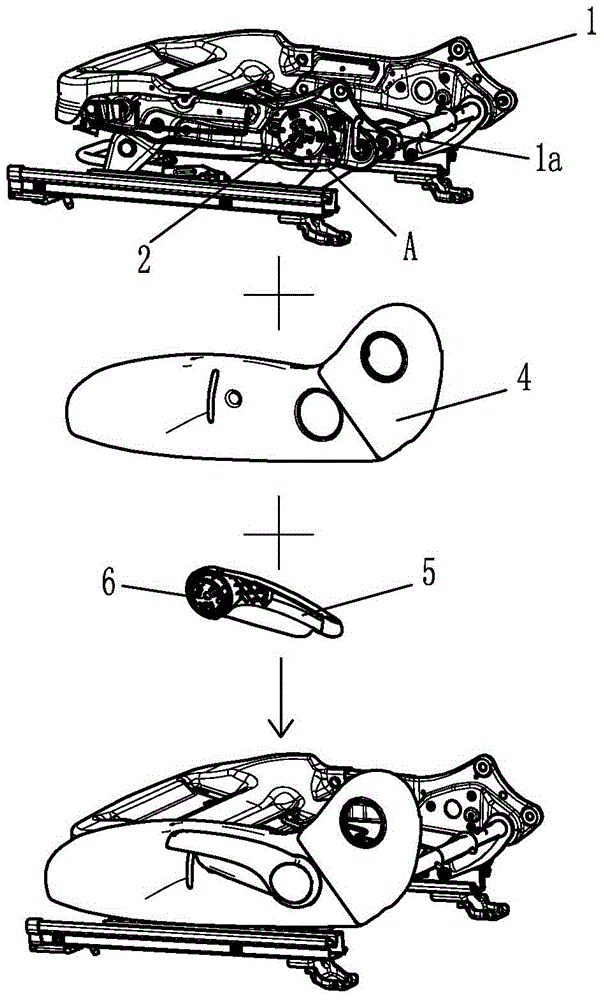

[0018] combine figure 2 — Figure 4 As shown, a seat height adjustment carrying structure is mainly composed of a seat frame skeleton assembly 1, a high-profile core part 2, an outer large guard plate 4 and a plastic handle 5.

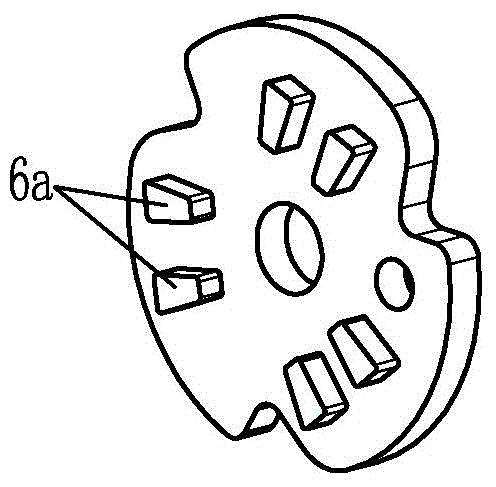

[0019] The high-profile core part 2 is purchased from the market, and its adjustment angle range is greater than the operating angle space of the plastic handle 5 . The high-profile core 2 usually consists of a fixed part and a rotating part. The high-profile core part 2 is installed on the side plate 1a of the seat frame skeleton assembly 1. The core part of the rotating part of the high-profile core part 2 is a rotating star-shaped boss 2a, and the core part of the fixed part is the shell sector cavity 2b, and the shell sector cavity 2b is in one-to-one correspondence with the rotating star-shaped boss 2a. The rotating star...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap