Span change structure of beam lifter

A beam lifting machine and main beam technology, which is applied in the direction of traveling mechanism, crane, trolley crane, etc., can solve the problems of long time and high labor intensity when changing the span, so as to reduce labor intensity, make it convenient to change the span, and improve the operation efficiency of the span change. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described below in conjunction with embodiment. The examples are used to illustrate the present invention, and do not limit the scope of protection of the present invention in any way.

[0024] combine Figure 1 to Figure 5 .

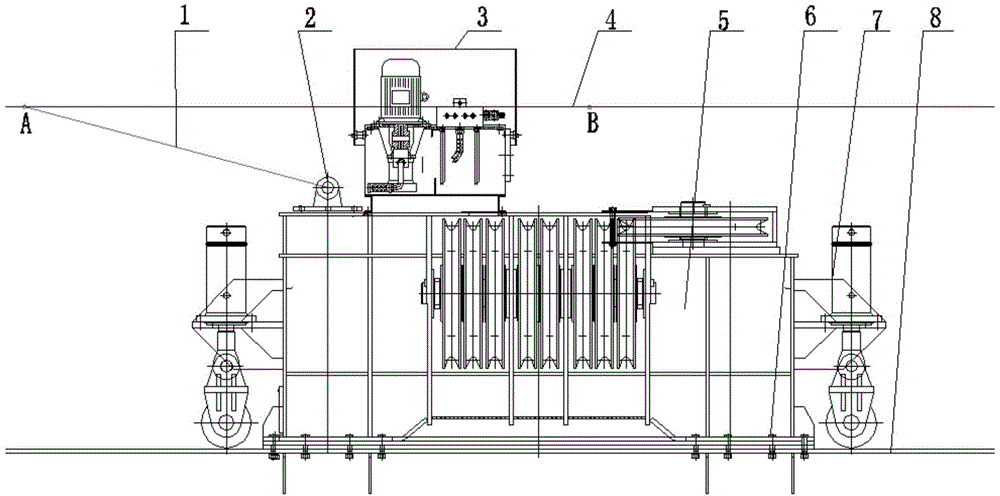

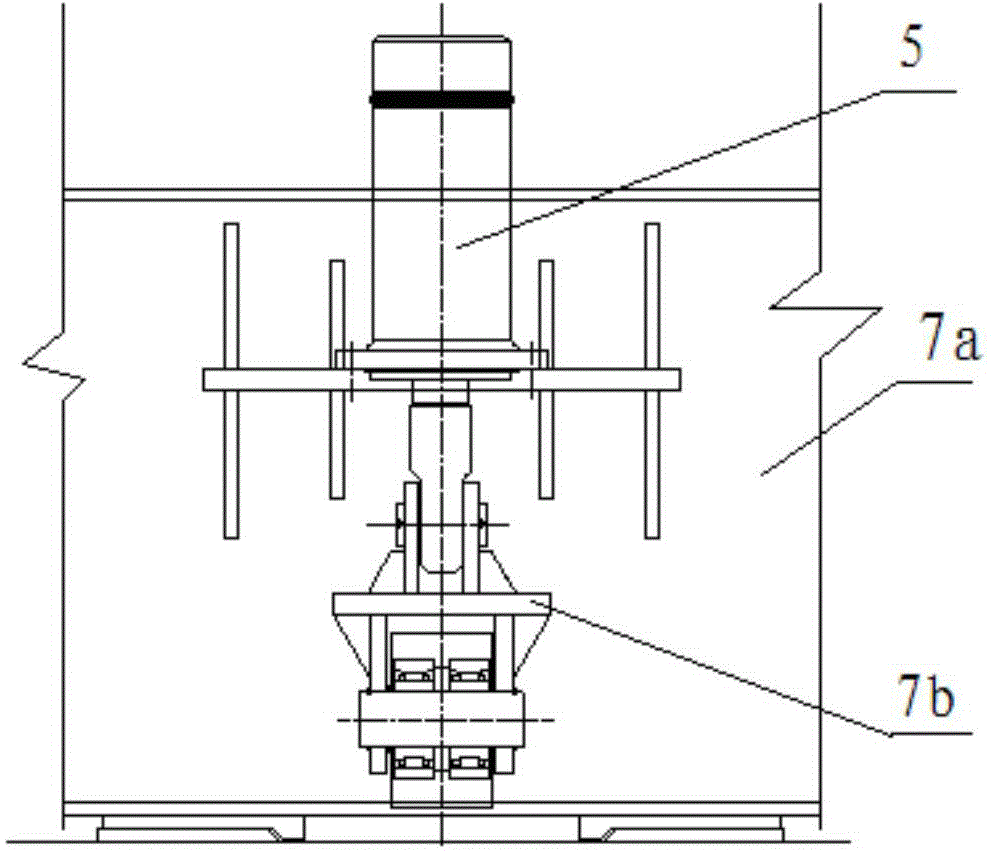

[0025] As shown in the figure, the beam lifting machine has a variable-span structure. The beam lifting machine is a kind of gantry crane, including the main beam 8, the variable-span crown crane 5 and the connecting bolts 6 between the main beam 8 and the variable-span crown crane 5, and the front and rear of the variable-span crown crane 5. Both ends are provided with running assembly 7, which includes moving roller 7b and vertical jacking cylinder 7a; variable-span crane 5 has lifting lug 2 and is detachably connected with hoist through wire rope 1.

[0026] The running assembly 7 is provided with at least 4 groups at the front and rear ends of the variable-span crane 5 .

[0027] The running assembly 7 is c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap