Rail layer walking process automatic span variation device and span variation method

A track-laying machine and automatic technology, applied in the direction of laying track, track, track maintenance, etc., can solve the problem of time-consuming and labor-intensive, and can not achieve zero-time crossing station and span change operation, etc., to improve the construction speed and facilitate the interval change. Operation, the effect of reducing auxiliary cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

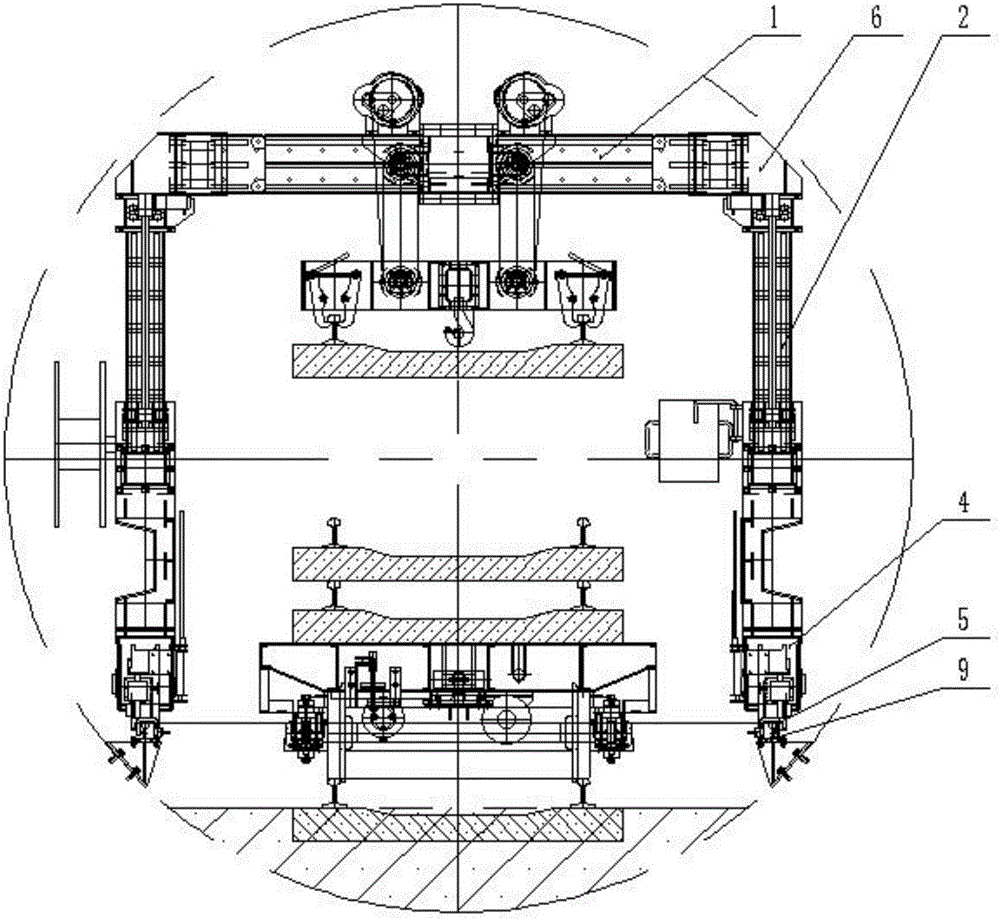

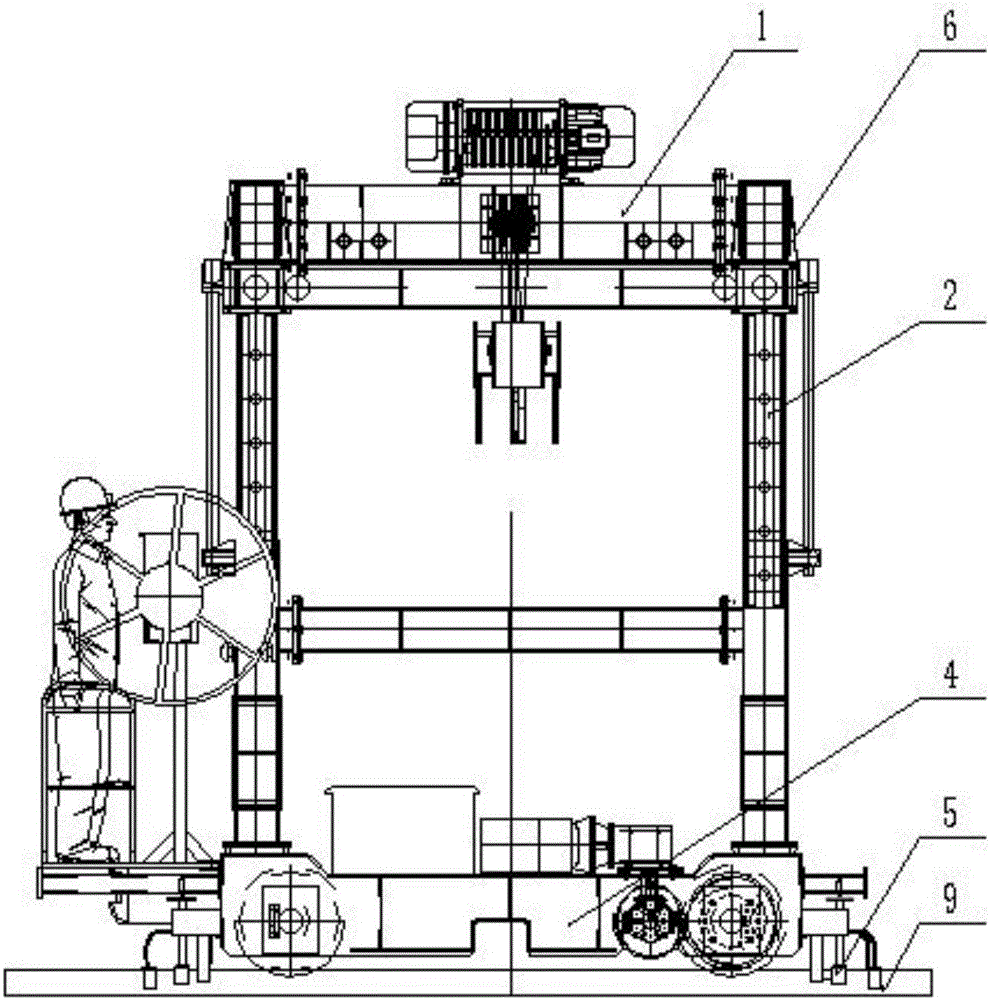

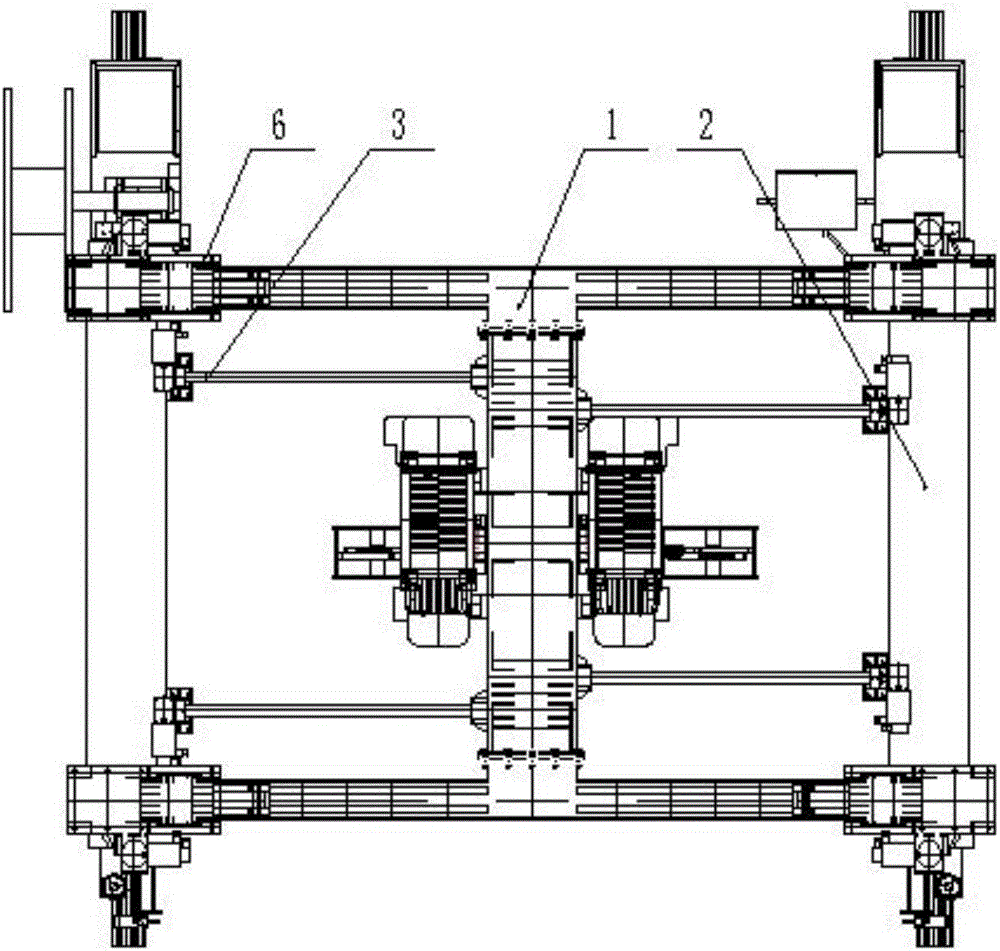

[0040] The automatic span change device during the track laying machine such as figure 1 , figure 2 , image 3 As shown, the main structural design of the present invention: the track-laying machine adopts the guide column type upper beam (1) and the upper beam guide sleeve (6) sliding mechanism, and the top of the leg (2) is fixedly connected with the upper beam guide sleeve (6). The bottom ends of the supporting legs (2) are fixed on the traveling beam (4), and an inductor (5) is respectively arranged on the side of the running track at the lower parts of the front and rear ends of the traveling beam (4). Traversing mechanism (3) drive motor is fixed on the support leg (2) longitudinal beam, and screw mandrel one end is connected with drive motor, and the other end is screwed in the articulated nut on the guide post type upper beam (1).

[0041]In addition, the auxiliary transition rail (7) is designed for the track-laying machine to change the span from the main line run...

Embodiment 2

[0043] In this embodiment, the method of automatically changing the span during the progress of the main line running track of the track laying machine and the shield tunnel running track is as follows: Figure 6 As shown, the specific steps are:

[0044] 1) Pull the track-laying machine into the field by the rail car, drive from the main line running track (8) to the working surface, release the connection between the rail car and the track-laying machine, turn on the power of the whole machine, remove the upper beam guide bush (6) and Position the load-bearing pins between the guide post type upper beams (1), install the auxiliary transition rails (7), and complete the preparation before spanning. Such as Figure 4 shown.

[0045] 2) Put down the sensor (5), switch the track-laying machine to the automatic span-changing mode, operate the track-laying machine to slowly drive through the auxiliary transition rail (7), and run to the transition trapezoidal track (10), the ele...

Embodiment 3

[0049] In this embodiment, the method of automatically changing the span between the running track of the shield tunneling section and the running track of the platform section is as follows: Figure 7 As shown, the specific steps are:

[0050] 1) The track laying machine travels along the running track (9) in the shield section to the starting point of the gauge change, stops and brakes, and removes the positioning bearing pin between the upper beam guide sleeve (6) and the guide column type upper beam (1). Such as Figure 7 shown.

[0051] 2) Put down the sensor (5), switch the track-laying machine to the automatic spanning mode, operate the track-laying machine to slowly drive into the transitional trapezoidal track (10), and the electric control system of the track-laying machine is based on the gauge change data detected by the sensor (5), Immediately issue an instruction, and the traversing mechanism (3) drives the motor to drive the screw mandrel, which drives the leg...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap