A new method for preparing urea compounds

A compound and urea technology, which is applied in the field of preparation of urea compounds, can solve the problems of easy oxidation, high toxicity, and troublesome operation, and achieve the effect of easy separation and purification, mild reaction conditions, and stable oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment one: synthetic compound (I-a)

[0024]

[0025] In a rigid glass tube add 3-bromo-3-benzylindolin-2-one (II) (0.1 mmol, 30.2 mg), O-tosyl-N-benzyloxycarbonylhydroxylamine (III) (0.15 mmol, 48.2 mg), CsCO 3 (0.2 mmol, 38.6 mg), then 2 ml of dichloromethane was added, and the mixture was stirred at room temperature for 14 h. Then p-toluenesulfonic acid (0.25 mmol, 43.1 mg) was added, and the reaction mixture was stirred at room temperature for 8 h. After the reaction was complete, the solvent was evaporated to dryness under reduced pressure to obtain a crude product. The crude product was separated and purified by column chromatography to obtain compound I-a, a white solid, with a yield of 94%.

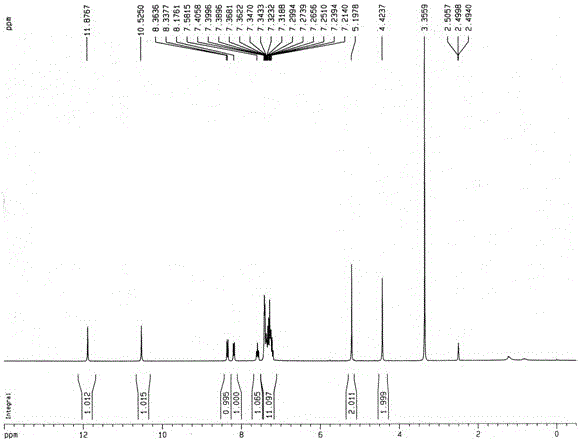

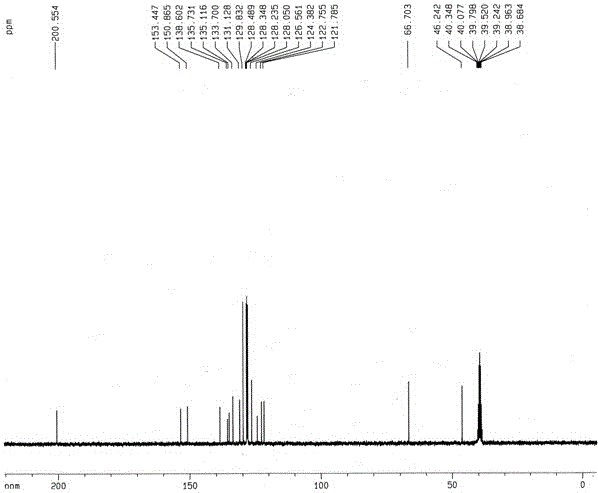

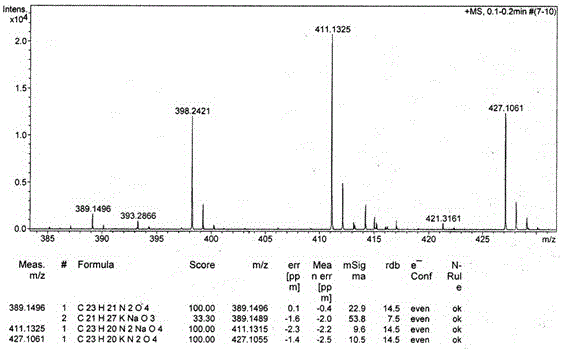

[0026] The proton spectrum, carbon spectrum and mass spectrum data of gained compound I-a are as follows:

[0027] 1 H NMR (DMSO-d 6 , 300 MHz), δ (ppm): 4.42 (s, 2H), 5.20 (s, 2H), 7.19-7.43 (m, 11H), 7.55-7.61 (m, 1H), 8.17-8.20 (m, 1H) , 8.35 (d, J = 7.8 H...

Embodiment 2

[0028] Embodiment two: synthetic compound (I-b)

[0029]

[0030] In a rigid glass tube add 3-bromo-3-(2-methylbenzyl)indolin-2-one (II) (0.1 mmol, 31.6 mg), O-tosyl-N-benzyl Oxycarbonyl Hydroxylamine (III) (0.15 mmol, 48.2 mg), K 2 CO 3 (0.2 mmol, 27.6 mg), then 2 ml of acetonitrile was added, and the mixture was stirred at room temperature for 16h. Then p-toluenesulfonic acid (0.25 mmol, 43.1 mg) was added, and the reaction mixture was further stirred at room temperature for 8 h. After the reaction was complete, the acetonitrile was evaporated to dryness under reduced pressure to obtain a crude product. The crude product was separated and purified by column chromatography to obtain compound I-b (white solid, yield 99%).

[0031] The proton spectrum, carbon spectrum and mass spectrum data of gained compound I-b are as follows:

[0032] 1 H NMR (DMSO-d 6 , 300 MHz), δ (ppm): 2.15 (s, 3H), 4.47 (s, 2H), 5.17(s, 2H), 7.15-7.18 (m, 4H), 7.24 (t, J = 7.8 Hz, 1H ), 7.34-...

Embodiment 3

[0033] Example 3: Synthesis of compound (I-c)

[0034]

[0035] In a rigid glass tube add 3-bromo-3-(3-methylbenzyl)indolin-2-one (II) (0.1 mmol, 31.6 mg), O-tosyl-N-benzyl Oxycarbonyl Hydroxylamine (III) (0.15 mmol, 48.2 mg), Et 3N (0.4 mmol, 40.4 mg), then 2 ml of toluene was added, and the mixture was stirred at room temperature for 30 h. Then p-toluenesulfonic acid (0.25 mmol, 43.1 mg) was added, and the reaction mixture was continued to stir at room temperature for 8 h. After the reaction was complete, the toluene was evaporated to dryness under reduced pressure to obtain a crude product. The crude product was separated and purified by column chromatography to obtain compound I-c (white solid, yield 92%).

[0036] The proton spectrum, carbon spectrum and mass spectrum data of obtained compound I-c are as follows:

[0037] 1 H NMR (DMSO-d 6 , 300 MHz), δ (ppm): 2.27 (s, 3H), 4.37 (s, 2H), 5.20(s, 2H), 7.04-7.06 (m, 3H), 7.18-7.23 (m, 2H), 7.34 -7.43 (m, 5H), 7.55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com