A temperature sensitive nano hydrogel and its preparation method and application

A nano-hydrogel, sensitive technology, applied in pharmaceutical formulations, medical preparations with inactive ingredients, etc., can solve the problems of difficult to control product purity, time-consuming purification process, poor biocompatibility, etc. Short response time, effect of reducing phase transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

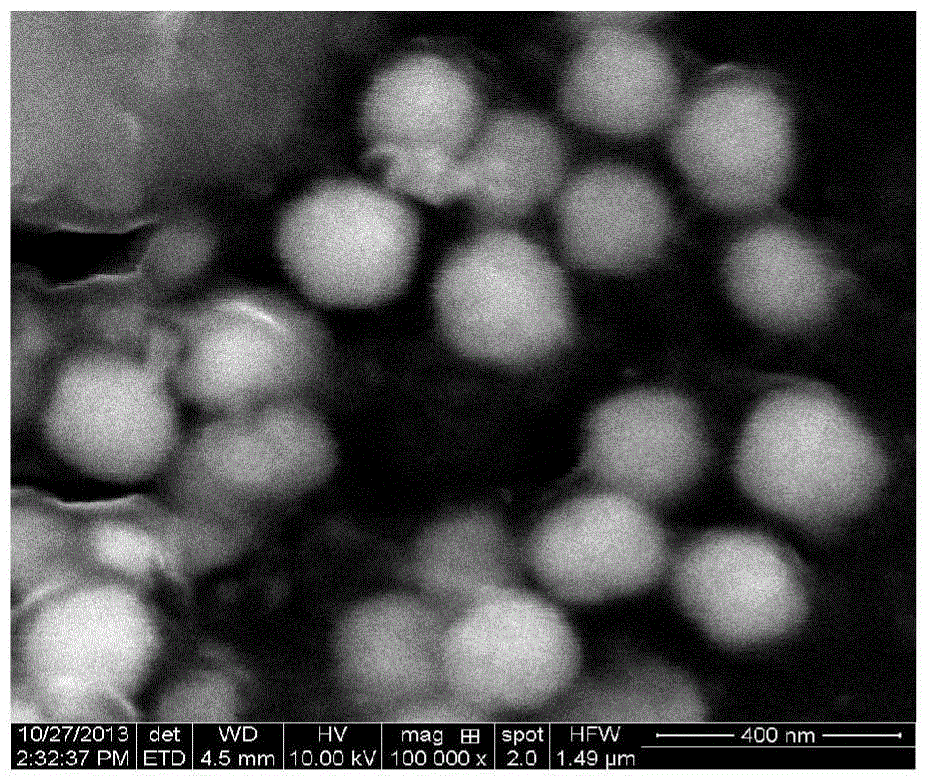

[0041] Methacrylic acid (0.105 mmol), polyethylene glycol diacrylate 575 (0.158 mmol), APS (10 wt% aqueous solution, 30 μL) and deionized water (50 mL) were added to a vial with a capacity of 100 ml. Nitrogen was purged for 10 min to remove free dissolved oxygen, then the vial was quickly sealed. Polymerization started at 70°C and continued for 4h. After cooling to room temperature, 400 μL (about 0.8% v / v) of a pH 1.0 hydrochloric acid solution in which 2M sodium chloride was dissolved was added to the polymer solution. The product was collected by centrifugation (10000 rpm). The resulting polymer hydrogel was redispersed in water and dialyzed at room temperature for 72 hours. After 24 hours of lyophilization and weighing, the yield of the obtained polymer hydrogel was 15.9%. The scanning electron microscope picture of product polyethylene glycol diacrylate-methacrylic acid copolymer nano hydrogel figure 1 , showing the morphology and particle size distribution of nano-hyd...

Embodiment 2

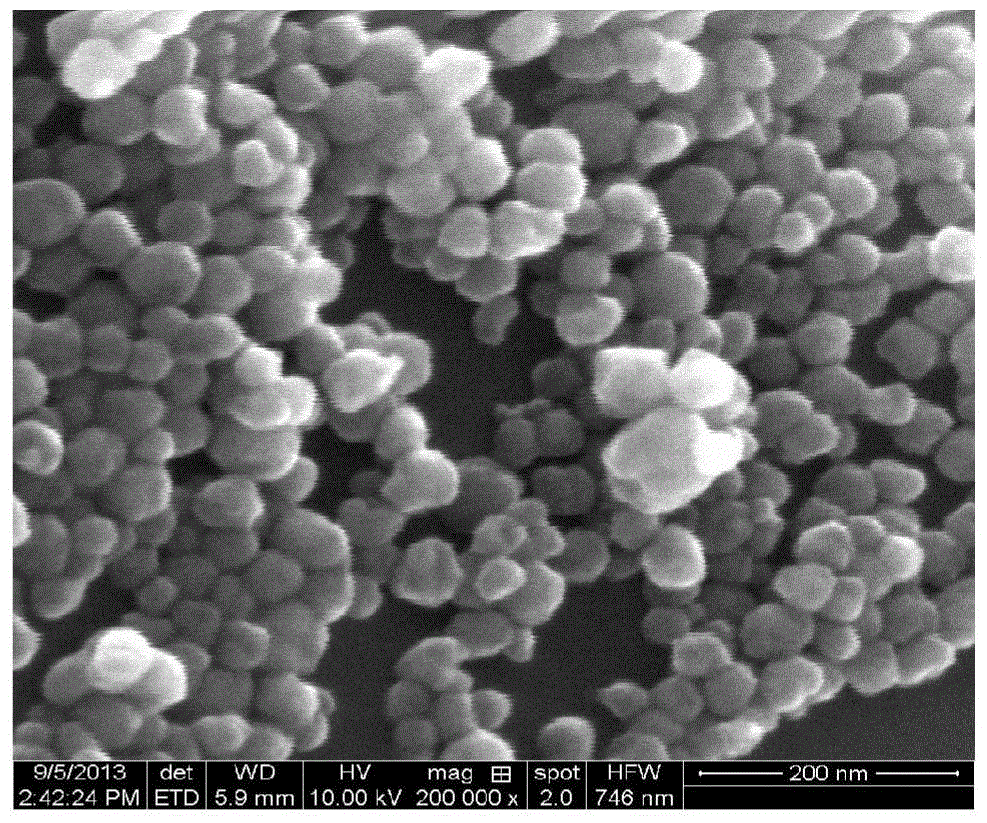

[0044] Methacrylic acid (0.211 mmol), polyethylene glycol diacrylate 575 (0.143 mmol), APS (10 wt% aqueous solution, 30 μl) and deionized water (50 mL) were added to a vial with a capacity of 100 ml. Nitrogen was purged for 10 min to remove free dissolved oxygen, then the vial was quickly sealed. Polymerization started at 70°C and continued for 4h. After cooling to room temperature, 400 μL of a hydrochloric acid solution at pH 1.0 in which 2M sodium chloride was dissolved was added to the polymer solution. The product was collected by centrifugation (10000 rpm). The resulting polymer hydrogel was redispersed in water and dialyzed at room temperature for 72 hours. After 24 hours of lyophilization and weighing, the yield of the obtained polymer hydrogel was 38.5%. The scanning electron microscope picture of product polyethylene glycol diacrylate-methacrylic acid copolymer nano hydrogel figure 2 , showing the morphology and particle size distribution of nano-hydrogel materia...

Embodiment 3

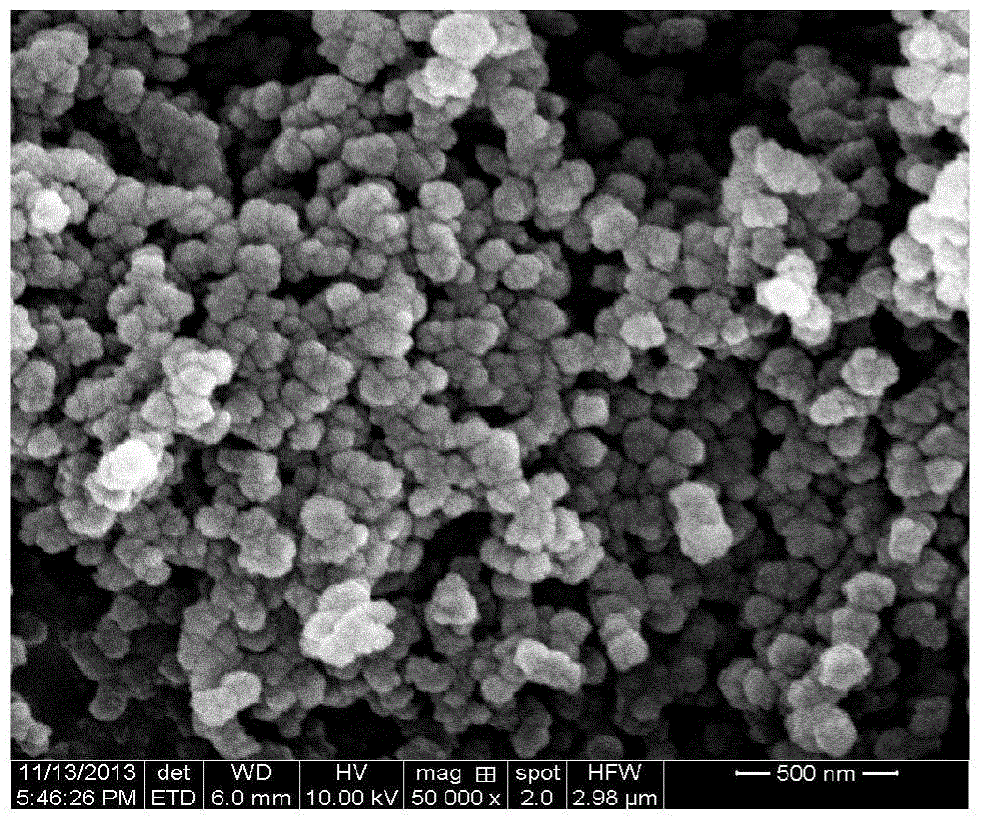

[0047] Methacrylic acid (0.435 mmol), polyethylene glycol diacrylate 575 (0.109 mmol), APS (10 wt% aqueous solution, 30 μl) and deionized water (50 mL) were added to a vial with a capacity of 100 ml. Nitrogen was purged for 10 min to remove free dissolved oxygen, then the vial was quickly sealed. Polymerization started at 70°C and continued for 4h. After cooling to room temperature, 350 μL of a pH 1.0 hydrochloric acid solution in which 2M sodium chloride was dissolved was added to the polymer solution. The product was collected by centrifugation (10000 rpm). The resulting polymer hydrogel was redispersed in water and dialyzed at room temperature for 72 hours. After 24 hours of lyophilization and weighing, the yield of the obtained polymer hydrogel was 50%. The dynamic particle size of the obtained copolymer nano hydrogel is 207nm. The scanning electron microscope picture of product polyethylene glycol diacrylate-methacrylic acid copolymer nano hydrogel image 3 , showing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com