Palm piece compressing device

A compression device, palm flake technology, applied in textile and papermaking, mechanical processing, fiber mechanical separation, etc., can solve the problems of pre-decomposition of unbreakable materials, single function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

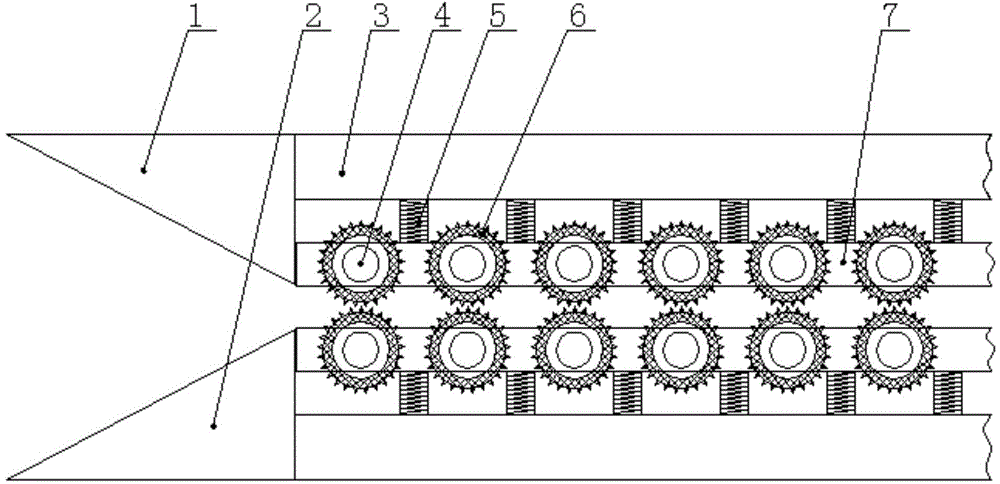

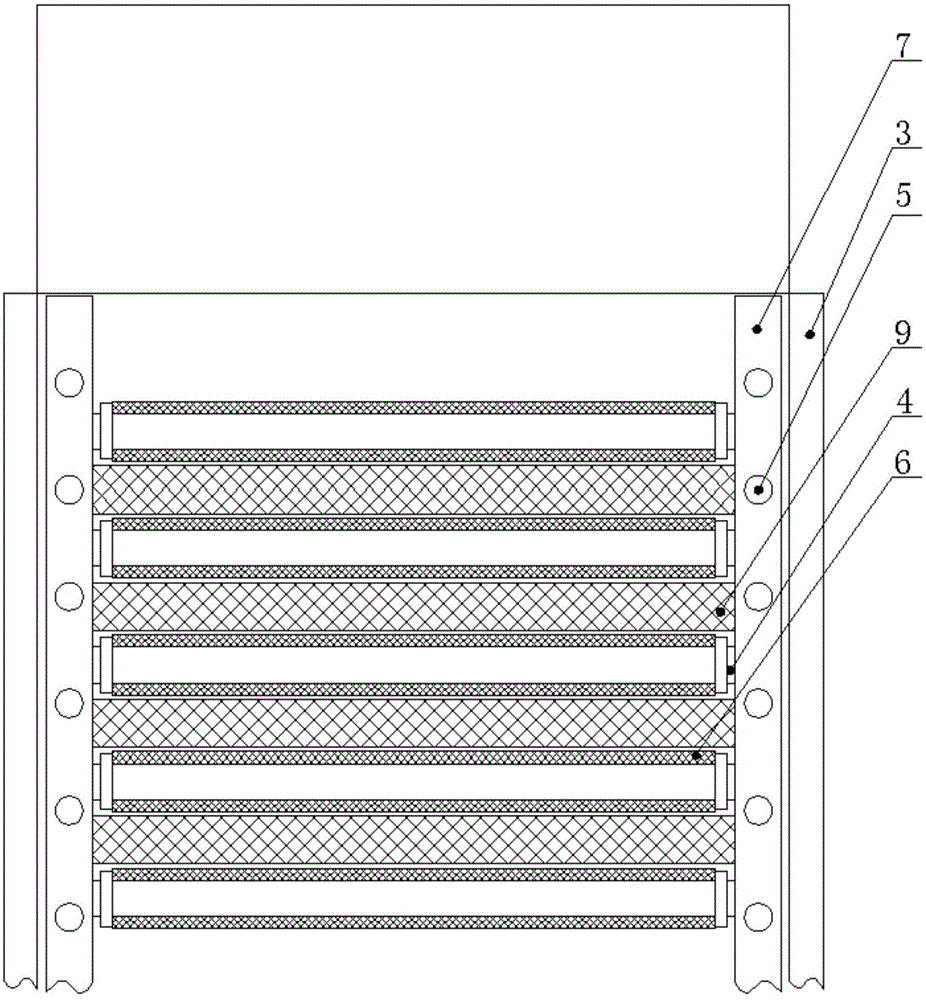

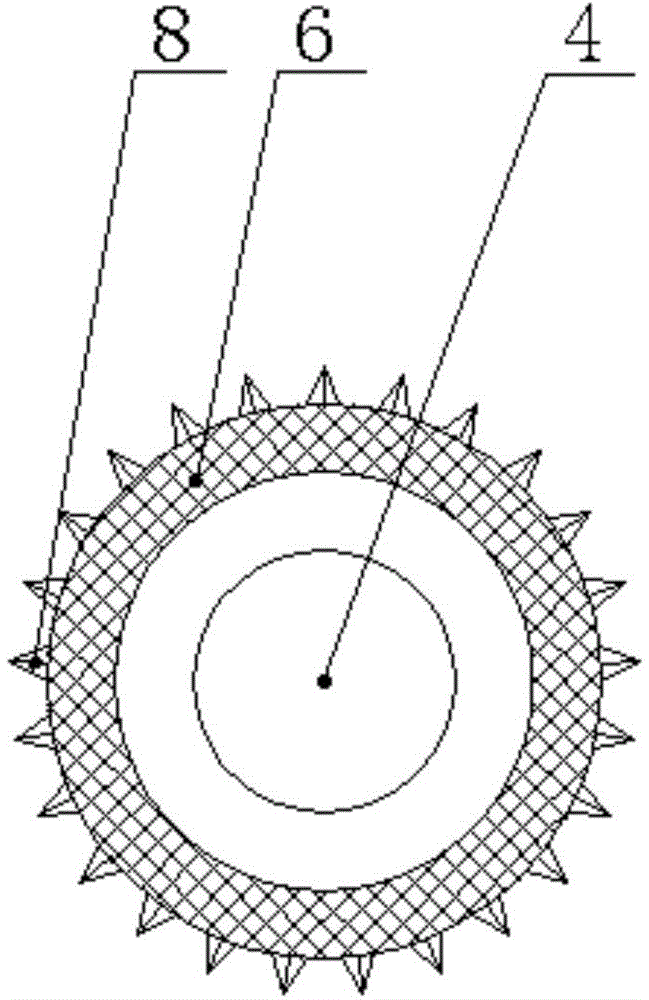

[0014] A brown sheet compression device is composed of a compression bin body 3, a fixed support frame 7 and a pressing wheel 6. The feeding end of the compression bin body is fixed with an upper briquetting block 1 and a lower briquetting block 2, and the upper and lower briquetting blocks in the compression bin body are A fixed support frame with the same structure and closely moving with the upper and lower pressure blocks is arranged symmetrically on the lower side. A plurality of horizontal support beams 4 are fixedly mounted on the fixed support frame. A plurality of crushing teeth 8 are evenly distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com