Orbital transfer portal crane matched with movable formwork

A technology of gantry cranes and mobile formwork, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of increasing assembly costs and prolonging the construction period, so as to save economic expenses, increase stability, reduce processing costs and The effect of assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further clearly and completely described in conjunction with the accompanying drawings in the embodiments of the present invention, and the described embodiments are only some of the embodiments of the present invention, not all of them.

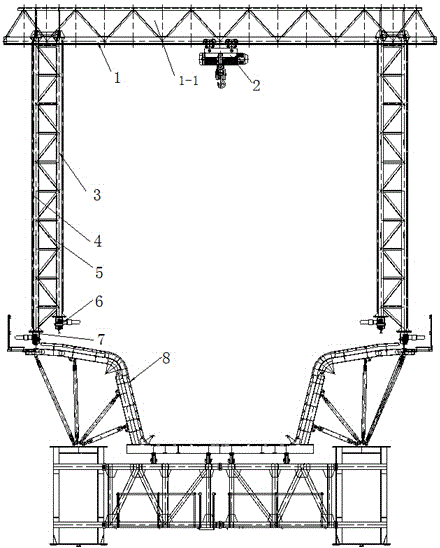

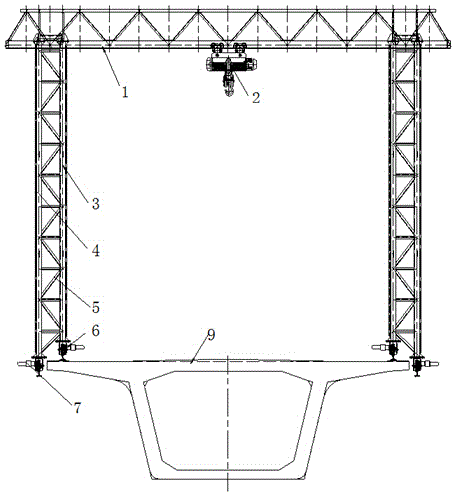

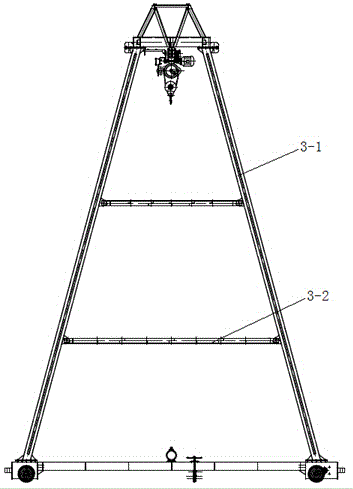

[0029] A mobile formwork supporting track changing gantry crane, comprising a main girder 1 extending in the left and right directions, the main girder 1 is a truss structure composed of section steel, and the main girder 1 includes a plurality of truss units 1-1 whose sections are inverted isosceles triangles , the electric hoist 2 is set under the main girder 1, and the left and right ends of the main girder 1 are fixedly connected with two outrigger groups respectively. Outer supporting legs 4 and inner supporting legs 3 arranged in parallel, and outer supporting legs 4 and inner supporting legs 3 are rigid supporting legs, and outer supporting legs 4 are equipped with an outer walking mechanism 7 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com