Connector for lengthening prestressed steel bars and construction method thereof

A technology of prestressed steel bars and connectors, applied in the processing of building materials, structural elements, building components, etc., can solve the problems of increased prestressed performance loss, loss of prestressed tendons, and large floor area, etc., to reduce prestressed Effects of stress loss, construction cost saving, and construction cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

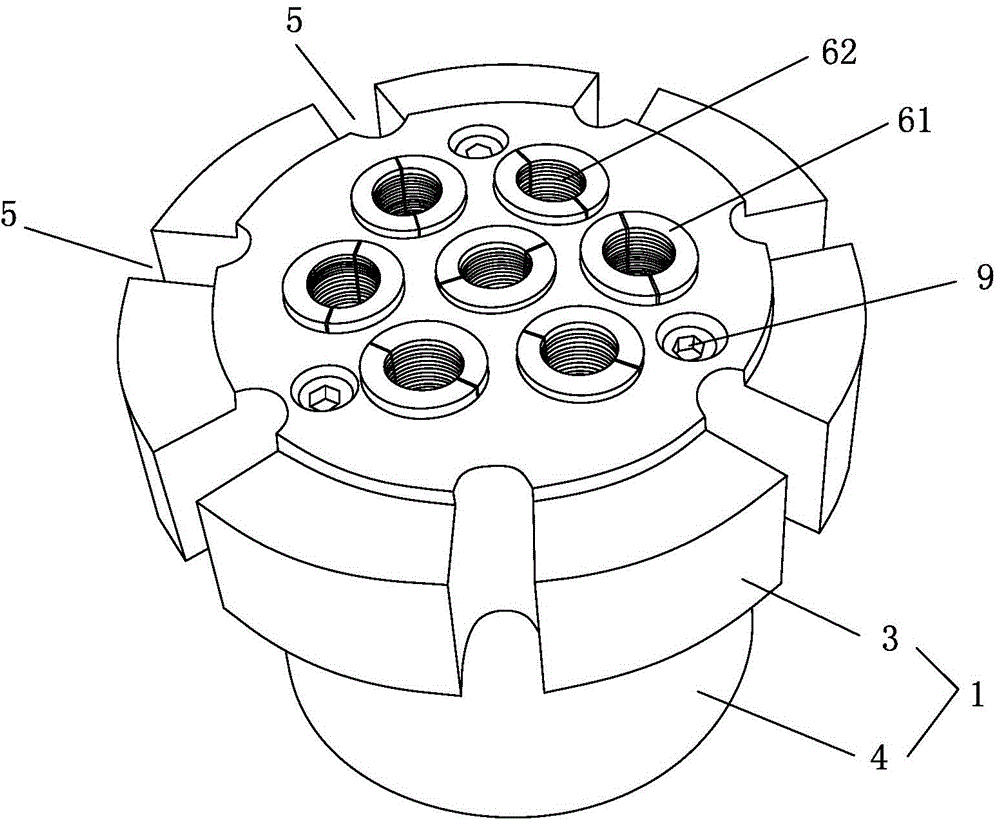

[0035] The present invention will be further described below with specific embodiment, see figure 1 -12:

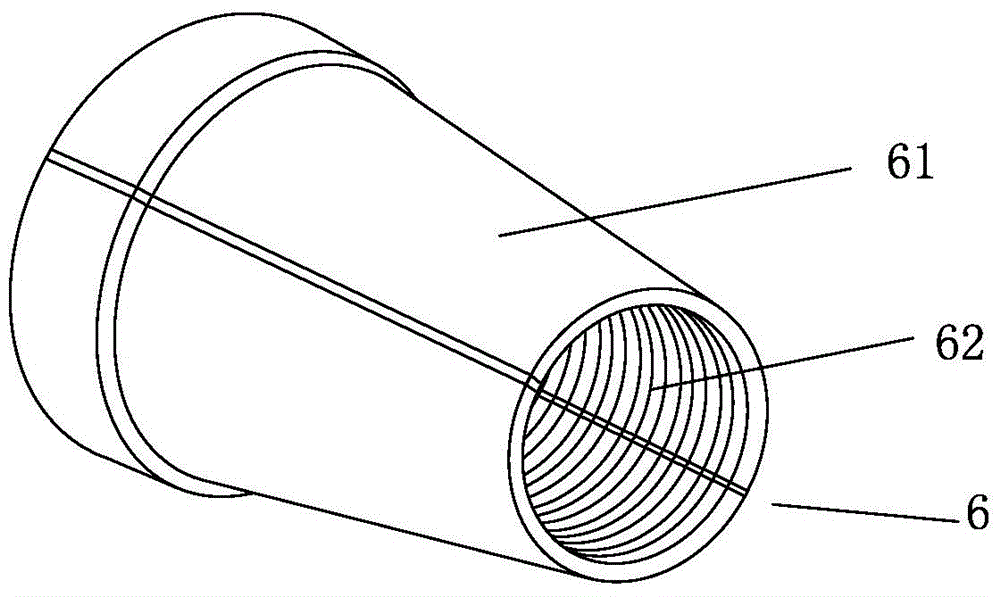

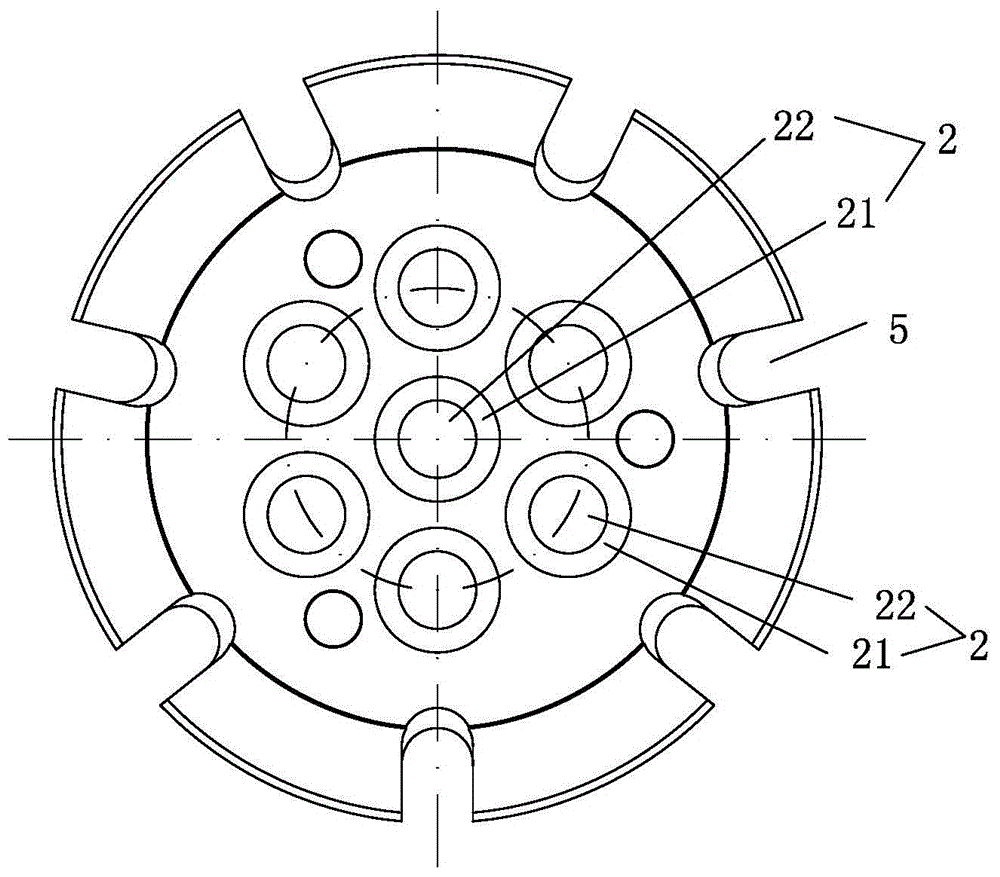

[0036] A connector for lengthening prestressed steel bars, including a body 1, and several steel bar holes 2 axially penetrating the body 1 are evenly distributed on the circumferential direction of the body 1, the steel bar holes 2 are used for installing prestressed steel bars 12, and the upper part of the body 3 The outer edge of the outer edge stretches out of the outer edge of the lower part 4, and there are several opening grooves 5 for installing prestressed steel bars evenly distributed on the outer edge of the upper body 3 in the circumferential direction, and the number of opening grooves 5 corresponds to the number of steel bar holes 2;

[0037] Or: the center of the body 1 is provided with a steel bar hole 2 axially penetrating the body 1, and several steel bar holes 2 axially penetrating the body 1 are evenly distributed on the outer circumference of the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com