Six-stroke engine and vehicle with it

An engine and six-stroke technology, which is applied in the direction of combustion engines, machines/engines, mechanical equipment, etc., can solve the problems of reducing the potential of six-stroke technology to reduce fuel consumption, and achieve the effects of reducing the difficulty of control and development, reducing fuel consumption, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

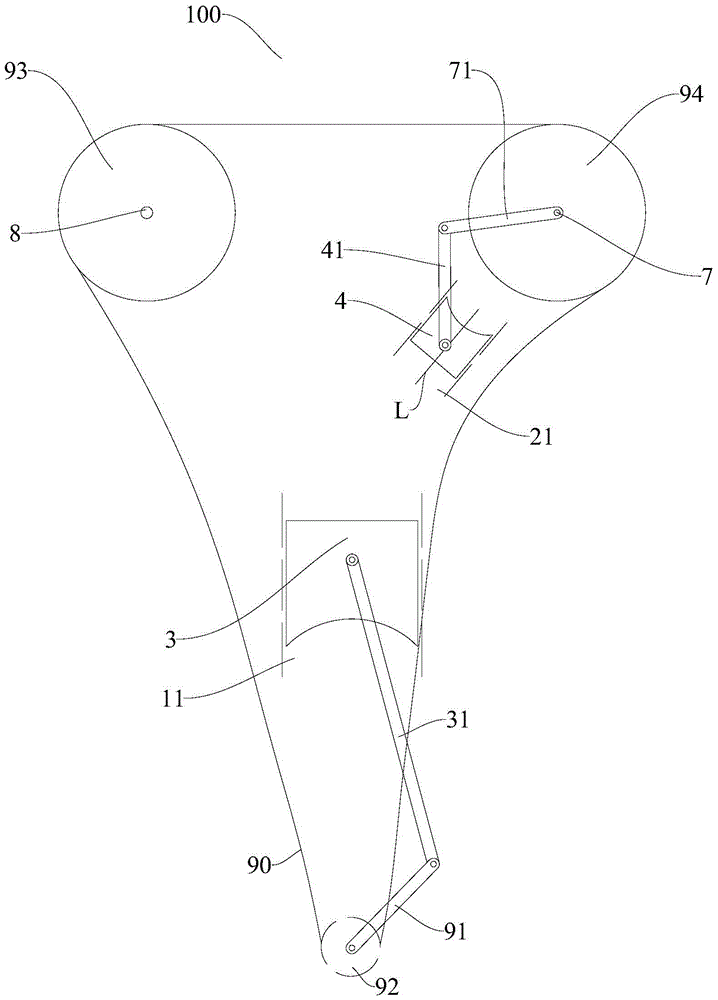

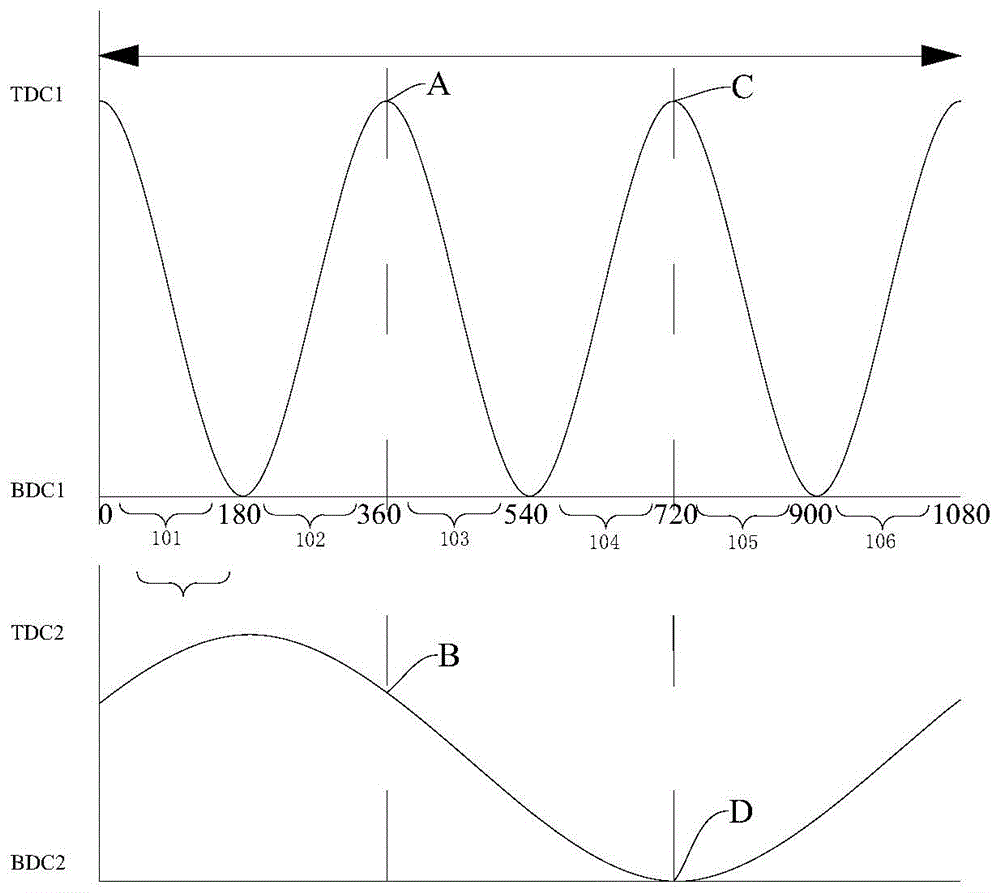

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples. It can be understood that the six-stroke engine 100 includes six strokes: intake stroke 101 , compression stroke 102 , power stroke 103 , recompression stroke 104 , repower stroke 105 and exhaust stroke 106 .

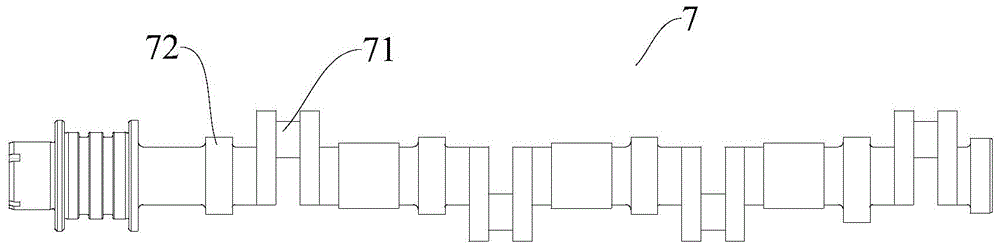

[0031] Such as Figure 1-Figure 6 As shown, the six-stroke engine 100 includes a cylinder block 1 , a cylinder head 2 , an intake valve 61 , an exhaust valve 62 , and a secondary piston 4 .

[0032] There is a cylinder 11 inside the cylinder block 1 , and a main piston 3 is arranged inside the cylinder 11 . The cylinder head 2 is arranged on the top of the cylinder block 1, and a combustion chamber 5 is defined between the cylinder head 2, the cylinder block 1 and the main piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com