Heavy rail abdominal cavity parameterization tolerance judging method

A judging method and parameterized technology, applied in the field of steel rolling, can solve the problems of inaccurate judging of abdominal cavity parameters of re-scanning section contours, inaccurate judging methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

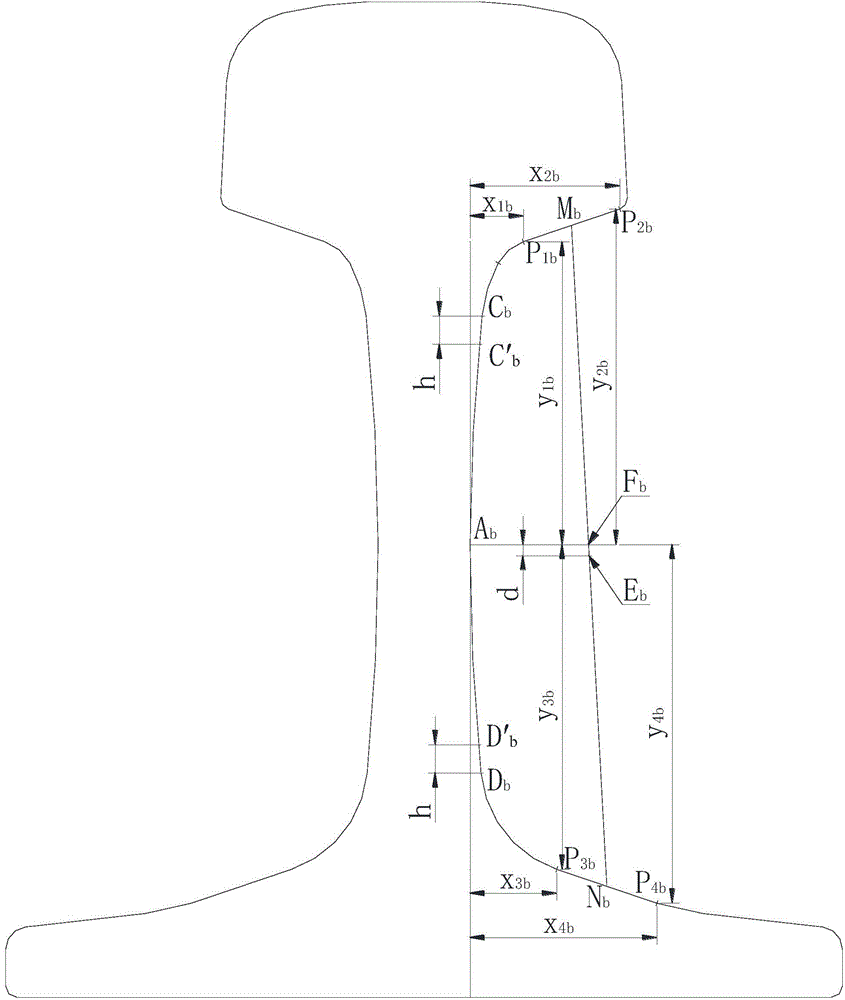

[0082] Such as figure 1 As shown in , set the horizontal axis of each scanning point of the standard cross-section profile of the heavy rail as a horizontal line, and the horizontal direction to the right is positive. The waist rail arc of the standard section profile of the heavy rail is where C b and D b are the two endpoints of the rail waist arc, A b (x Ab ,y Ab ) is the midpoint of the waist rail arc of the standard section profile of the heavy rail, C b and D b Along the rail waist arc respectively to A b After the point is offset by h=5.00mm in the direction of the longitudinal axis, C′ can be obtained respectively on the circular arc of the waist rail of the standard section profile of the heavy rail b (x C′b ,y C′b ) and D' b (x D′b ,y D′b ) two points, remember t 1 =(x C′b +x D′b ) / 2-x Ab , for 60kg / m heavy rail, at this time t 1 is a fixed value.

[0083] P 1b (x P1b ,y P1b ) and P 2b (x P2b ,y P2b ), the arc center A of the rail waist b w...

no. 2 example

[0137] In combination with the above description of the standard profile of the heavy rail section, the steps of the second embodiment are as follows:

[0138] Step 1: Determine the benchmark

[0139] 1. If Figure 4 , find the point K(x K ,y K ), where x K It is the minimum value of the abscissa of all points on the arc of the rail waist; find the y coordinate on the slant line of the lower jaw of the rail head to find the profile of the heavy rail scanning section K +y 1b / 2+y 2b / 2 point M′(x M′ ,y M′ ), find the vertical coordinate on the oblique line on the rail leg of the scanning section profile of the heavy rail is x K +y 3b / 2+y 4b / 2 point N′(x N′ ,y N′ ); find the ordinate on the rail waist arc of the heavy rail scanning section contour as (y M′ +y N′ ) / 2+d point A(x A ,y A ).

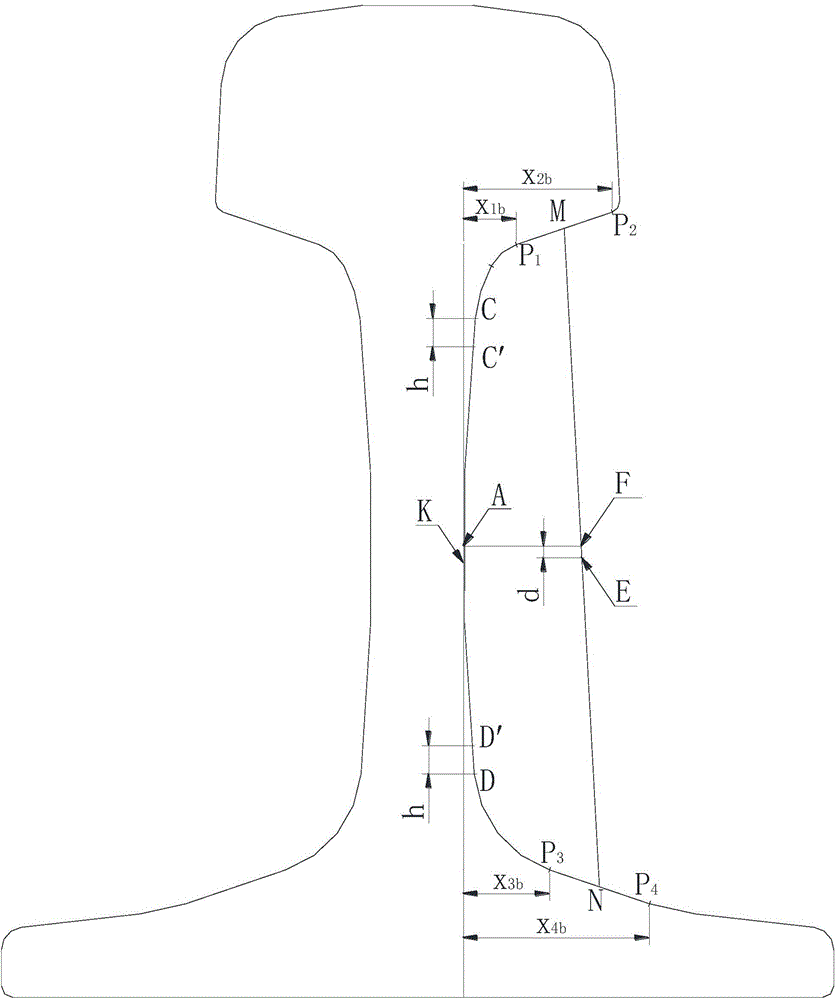

[0140] Among them, y 1b 、y 2b 、y 3b 、y 4b The meanings represented by , d are the same as those in the first embodiment. Such as Figure 4 As shown, M' is P' on the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com