Method for testing buffer performance of two-dimensional porous material under high-speed impact condition

A high-speed impact, porous material technology, applied in the direction of analyzing materials, measuring devices, strength characteristics, etc., can solve the problems that cannot be used to study the buffer performance of two-dimensional porous materials, and achieve the effect of simple evaluation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Determination of the dynamic cushioning performance of the aluminum circular two-dimensional porous material with R=3mm and t=0.07mm under the coplanar impact velocity of v=70m / s.

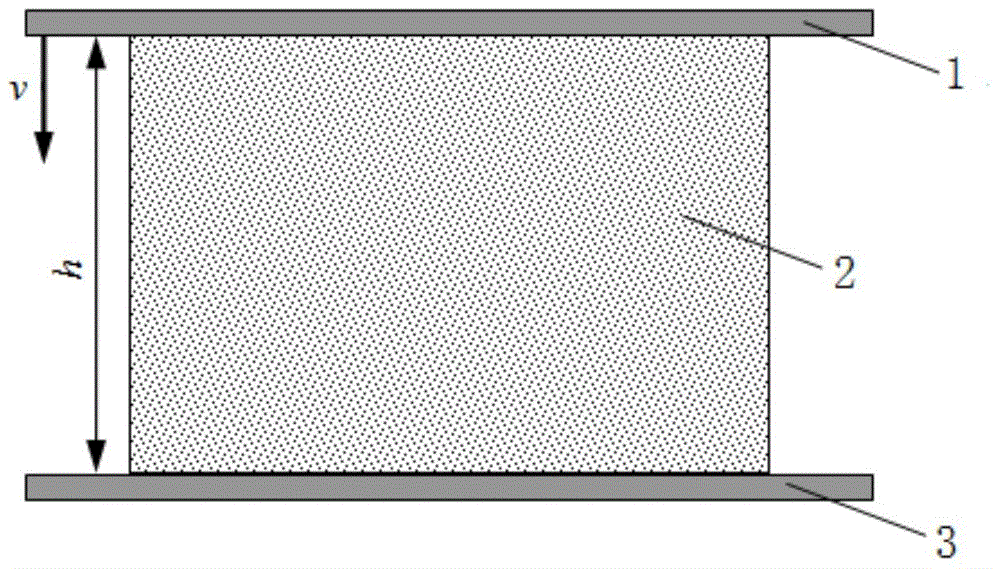

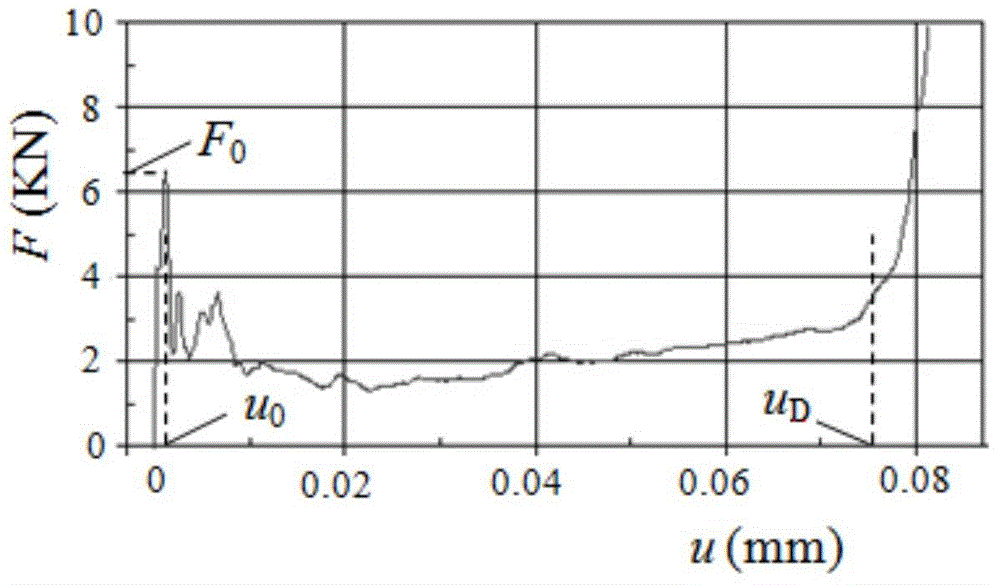

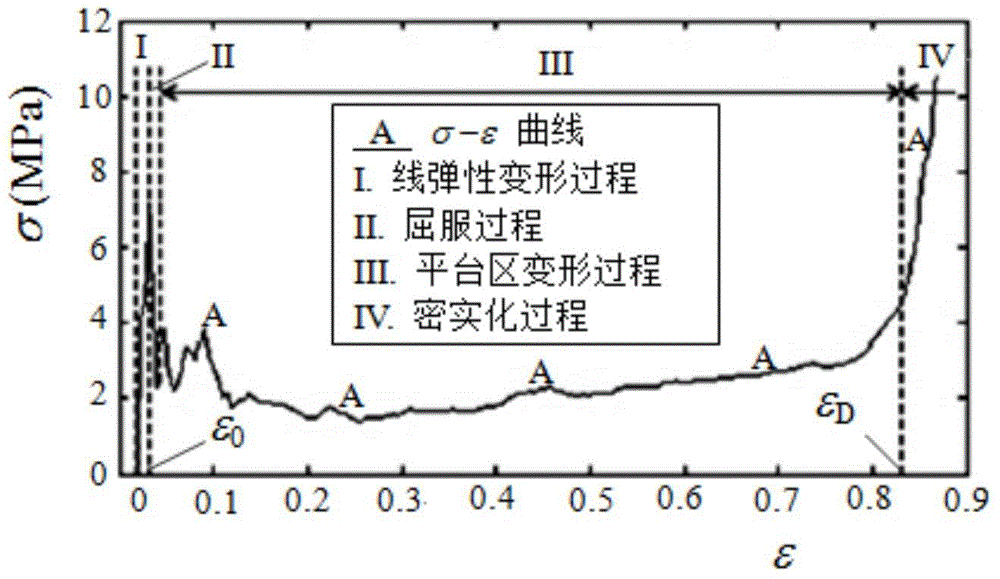

[0044] Taking a circular two-dimensional porous material as an example to illustrate the steps and feasibility of this method, the schematic diagram of the dynamic impact test is shown in Figure 5 shown. The shape of the sample is cuboid, the cross-sectional width (that is, the depth of the unit hole) b=90mm, and the number of units arranged in both directions of the coplanar plane is 16, then the length of the rectangular cross-section of the sample along the impact direction l=96mm, along the impact direction The length of the upper sample is h=96mm, and the size is large enough to eliminate the influence of the boundary. The radius of each unit in the sample is R=3mm, and the wall thickness t=0.07mm, then the density of the circular two-dimensional porous material sample is Among them...

Embodiment 2

[0046] Determination of dynamic cushioning performance of aluminum triangular two-dimensional porous material with l=3mm, θ=60°, t=0.15mm under coplanar impact velocity of v=50m / s.

[0047] The three-dimensional structure of triangular two-dimensional porous material is shown in the figure Figure 8 As shown, l is the length of the hypotenuse of the triangular characteristic unit, and θ is the base angle of the unit. Sample depth b=30mm, x 1 and x 2 The number of characteristic units in each direction is 8×10, and the external dimensions of the sample are h=20.7848mm, l=30mm. The F-u curve is obtained by the test, the σ-ε curve can be obtained after standardization, and the e-ε curve can be obtained after integrating the σ-ε curve. The σ-ε and e-ε curves are respectively as follows Figure 9 with 10 shown. Then the sample density ρ * = 1 + cos θ ...

Embodiment 3

[0049] l = 3mm, t = 0.1mm aluminum square two-dimensional porous material to determine the dynamic cushioning performance under the coplanar impact velocity of v = 20m / s.

[0050] The three-dimensional structure of the square two-dimensional porous material is as follows: Figure 11 As shown, l refers to the side length of the square characteristic unit. Sample depth b=40mm, x 1 and x 2 The number of characteristic units in each direction is 15×13, and the external dimensions of the sample are h=45mm, l=39mm. The F-u curve is obtained by the test, the σ-ε curve can be obtained after standardization, and the e-ε curve can be obtained after integrating the σ-ε curve. The σ-ε and e-ε curves are respectively as follows Figure 12 with 13 shown. Get the sample density ρ * =2t / l(1-t / (2l))=177kg / m 3 , the initial strain ε 0 =0.0038, densification strain ε D =0.8562, initial peak stress σ 0 =5.8670MPa, dynamic peak stress σ p = 0.8814MPa. Obtain each buffer performance eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Yield stress | aaaaa | aaaaa |

| Dimensions | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com