Novel constant-temperature and constant-humidity salt spray testing device

A salt spray test, constant temperature and humidity technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of unable to form uniform and stable airflow, insufficient atomization, unable to obtain mist, etc., to achieve good drainage and overflow structure, Reasonable design, excellent effect of saving the ability to use salt spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

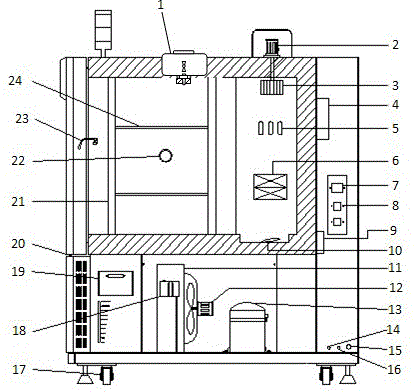

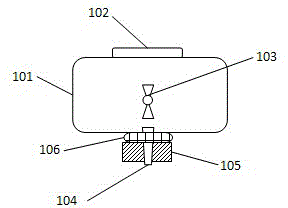

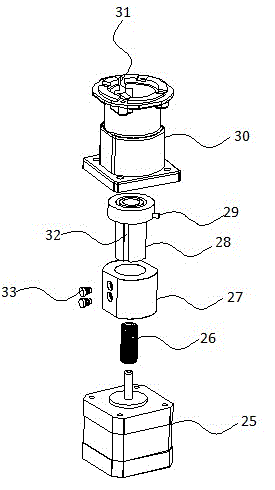

[0026] like figure 1 and figure 2 As shown, a new type of constant temperature and humidity salt spray test device, the salt spray test device includes a box, a test chamber, a humidifier 10, a cooling device, a heater 5, an evaporator 6, a water tank, a circulation device, Salt mist generator 1. Driving device. The test chamber is set inside the box body. The test chamber is a test place. The test chamber is a stainless steel cabinet with an inner wall coated with an anti-salt spray layer.

[0027] The test room is provided with a test bracket 21 on the side where the door of the box is opened. The test bracket 21 is provided with a storage tray 24. The inside of the test room is respectively equipped with a circulation device, a heater 5, and an evaporator 6 from top to bottom. And the humidifier 10, the test chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com