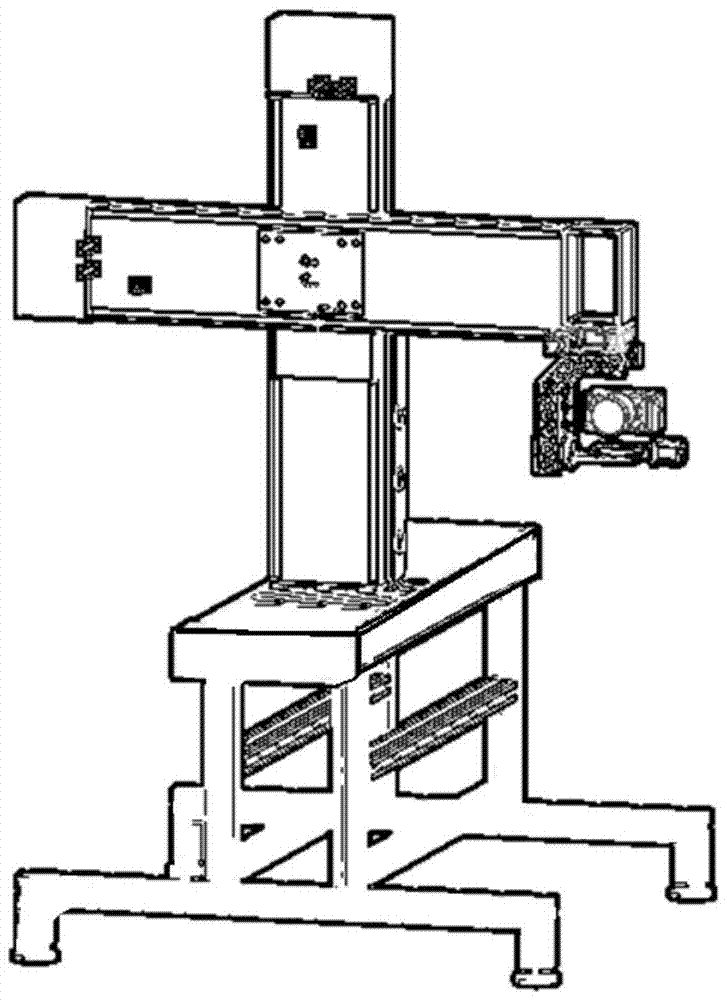

Crane-mounted professional stop motion and photography system

A rocker-type, professional technology, applied in optics, instruments, camera bodies, etc., can solve problems such as shooting failure, camera push, Y-axis motion, etc., to achieve flexible camera position adjustment, small footprint, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

[0033] The invention provides a rocker-type professional stop-frame shooting and photography system, which has four main design features: a rocker arm frame, an electric drive system, a concentric axis wiring method, and a 3D three-dimensional shooting platform design. These four areas are described in detail below:

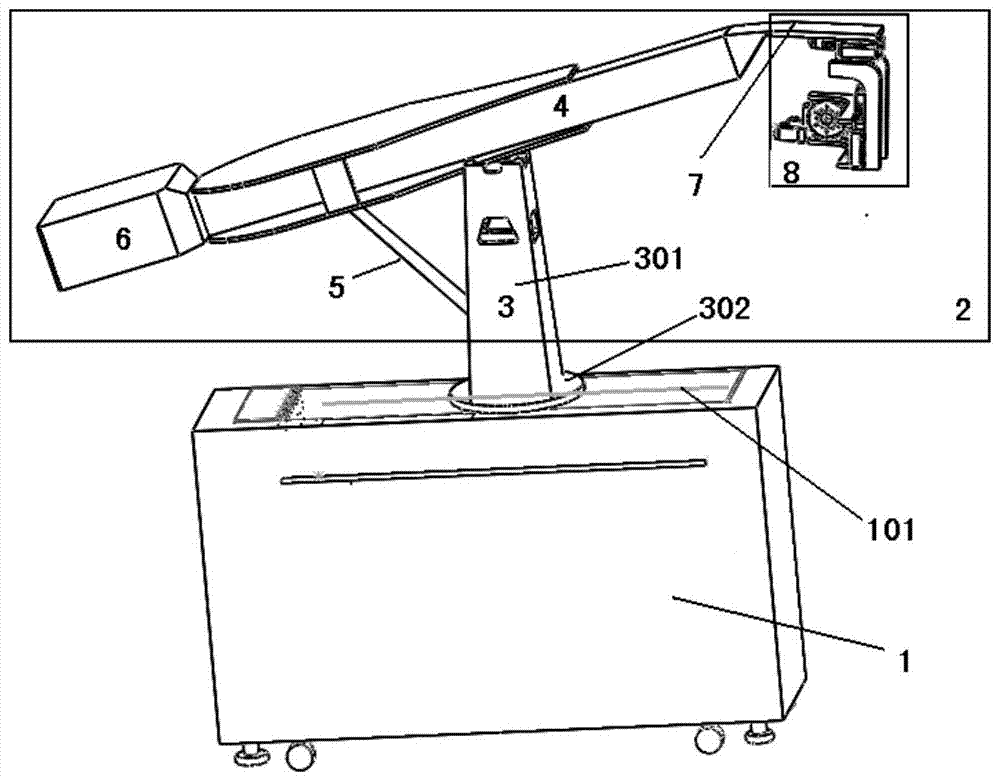

[0034] (1) Rocker arm bracket

[0035] Such as Figure 2-3 As shown, the present invention provides a rocker-type professional stop-frame shooting and photography system, comprising: a base 1 and a rocker frame 2;

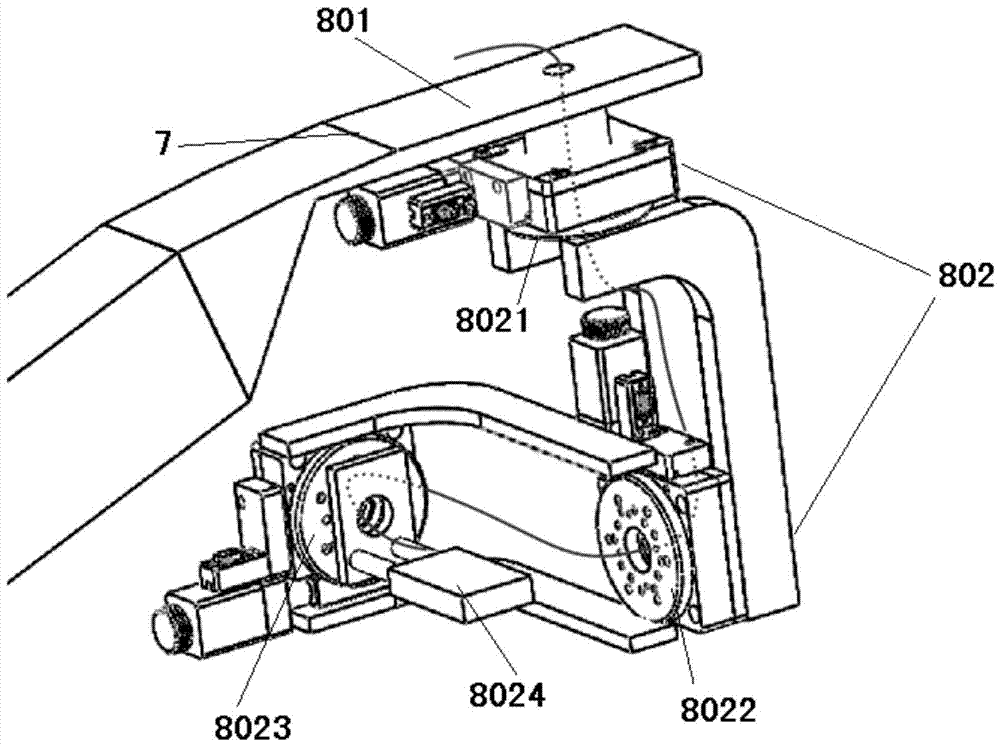

[0036] (1) Rocker arm body

[0037] Rocker arm frame 2 includes: rocker arm horizontal rotation shaft 3, rocker arm 4, hydraulic rod 5, counterweight 6, camera level controller 7 and machine head 8;

[0038] The machine base 1 is used to stably support the entire rocker arm frame, and a horizontal slide rail 101 is fixedly arranged on the top surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com