ZigBee-based equipment monitoring system and monitoring method thereof

A technology for equipment monitoring and equipment, which is applied in the general control system, control/regulation system, transmission system, etc., can solve the problems of equipment users' loss and inability to monitor and maintain equipment in real time, so as to save wiring costs, improve equipment maintenance efficiency, Capture flexible and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

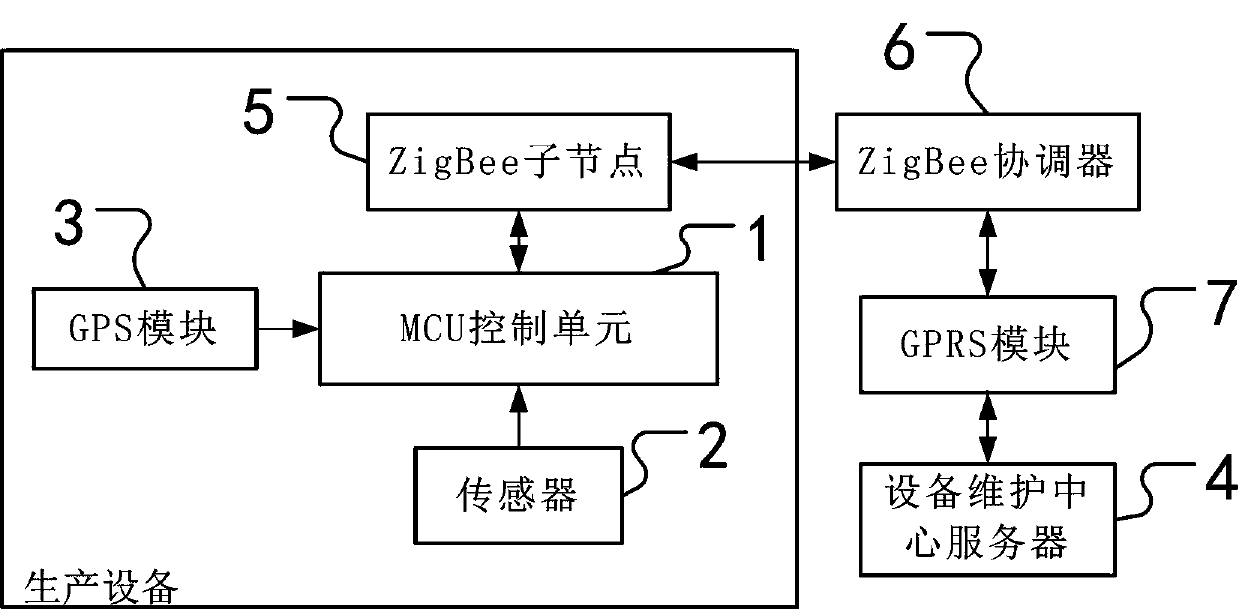

[0052] Example 1: Such as figure 1 As shown, a ZigBee-based equipment monitoring system includes

[0053] The mechanical parts of the equipment, the mechanical parts of the equipment are the mechanical mechanism of the equipment to complete the production task; and the following monitoring system parts.

[0054] An MCU control unit 1, which is set on the device. The MCU control unit 1 is used to control the running state of the device and to process data information. The control unit MCU can control various operating parameters of the device, control the operation of the device, collect data from each sensor 2, collect GPS data, and perform data processing; and can realize data communication with the ZigBee subnode 5.

[0055] At least one sensor 2 is installed on the device; the sensor 2 is connected to the MCU control unit 1. The sensor 2 is used to collect and transmit the operating parameter information of the equipment in various production processes. The important production...

Embodiment 2

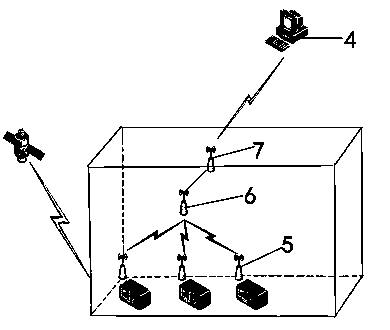

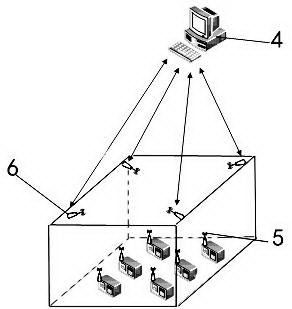

[0071] Example 2, such as Figure 5 , Image 6 As shown, a monitoring method of a ZigBee-based device monitoring system includes the following steps.

[0072] S1: When the equipment is transported, load the equipment on the truck.

[0073] S2: The GPS module 3 collects the real-time position information of the equipment at a set time interval, and transmits the real-time position information to the equipment maintenance center server 4 through the ZigBee module.

[0074] Specifically: a ZigBee coordinator 6 and a GPRS module 7 are installed in the truck compartment. The ZigBee coordinator 6 communicates with the ZigBee child node 5 on the device during transportation, and the GPS module 3 obtains relevant position information and passes the position information through the ZigBee module Transfer to the server 4 of the equipment maintenance center. The GPRS module 7 is responsible for uploading the data collected by the ZigBee coordinator 6 through the GPRS network. During transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com