Multifunctional durable plowshare and operating method thereof

A multi-functional, plowshare technology, applied in plowing, application, agriculture, etc., can solve problems such as single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

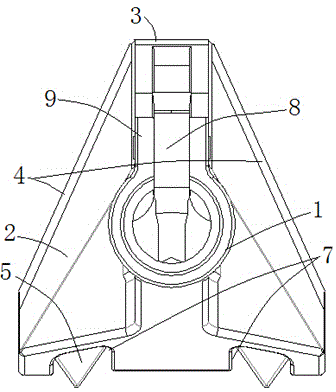

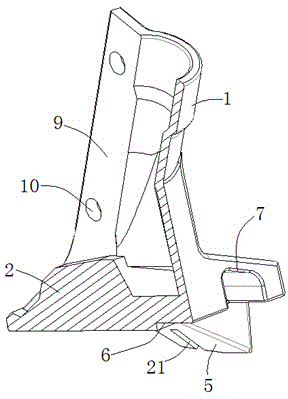

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0020] see Figure 1 to Figure 2 , the present invention provides a multifunctional and durable plowshare, including a bushing 1 for installing a plow shaft (not shown) and a plowshare main body 2, the front end of the plowshare main body 2 is welded with a hard alloy The plow share 3, the two sides of the plow share main body 2 are welded with side blades 4 made of cemented carbide, the bottom of the plow share main body 2 is provided with two discharge ports 21, the discharge ports 21 and the The shaft sleeve 1 communicates and forms a channel, which can be used for seeds or fertilizers to pass through to the ground.

[0021] Further, the shape of the plowshare main body 2 is a symmetrical isosceles triangle structure, and the shape of the plowshare 3 is a tongue-like protrusion type or an ax bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com