Drum-type heavy rake

A drum-type, heavy-harrowing technology, applied in the field of farmland farming, can solve the problems of low seedling survival rate, too large gap, loss of moisture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

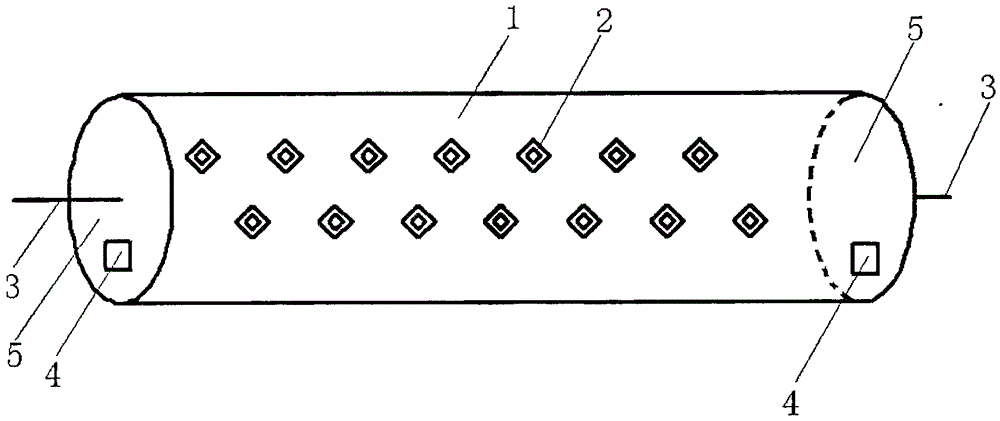

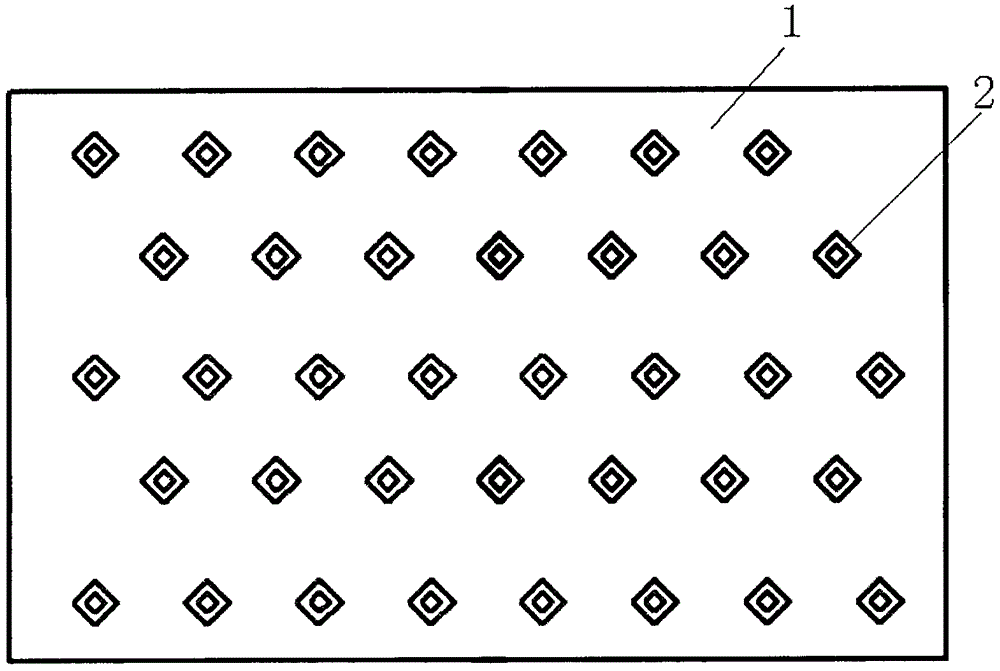

[0008] As shown in the figure: select a high-quality steel plate 1 with a thickness of 1cm, a length of 2.5m, and a width of 1.3m, and weld the prismatic rake teeth 2 on the selected 1 according to a rhombus distribution, and curl the steel plate 1 after welding the prismatic rake teeth 2 Become a drum, make circular steel plates 5 at both ends of the drum, drive shaft 3 is set at the center of the circular steel plate 5, the bottom of the drive shaft 3 is provided with a weight switch 4, and the circular steel plate 5 is welded on the drum to make it closed.

[0009] Through the transmission shaft 3, the drum-type heavy harrow is connected to power equipment such as tractors and rotary tillers,

[0010] The net weight of the heavy rake is about 600 kg, and the weight of the rake can reach more than 1000 kg by adding water or sand through the weight switch 4.

[0011] The invention is suitable for compaction and flattening of various soils after plowing, especially for loam so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com