a bone cutter

A bone cutter and frame technology, which is applied in slaughtering, meat processing equipment, food science, etc., can solve the problems of different sizes of processed aggregates, personal safety of operators, etc., and achieve uniform size and consistent feed rate , the effect of avoiding the danger of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

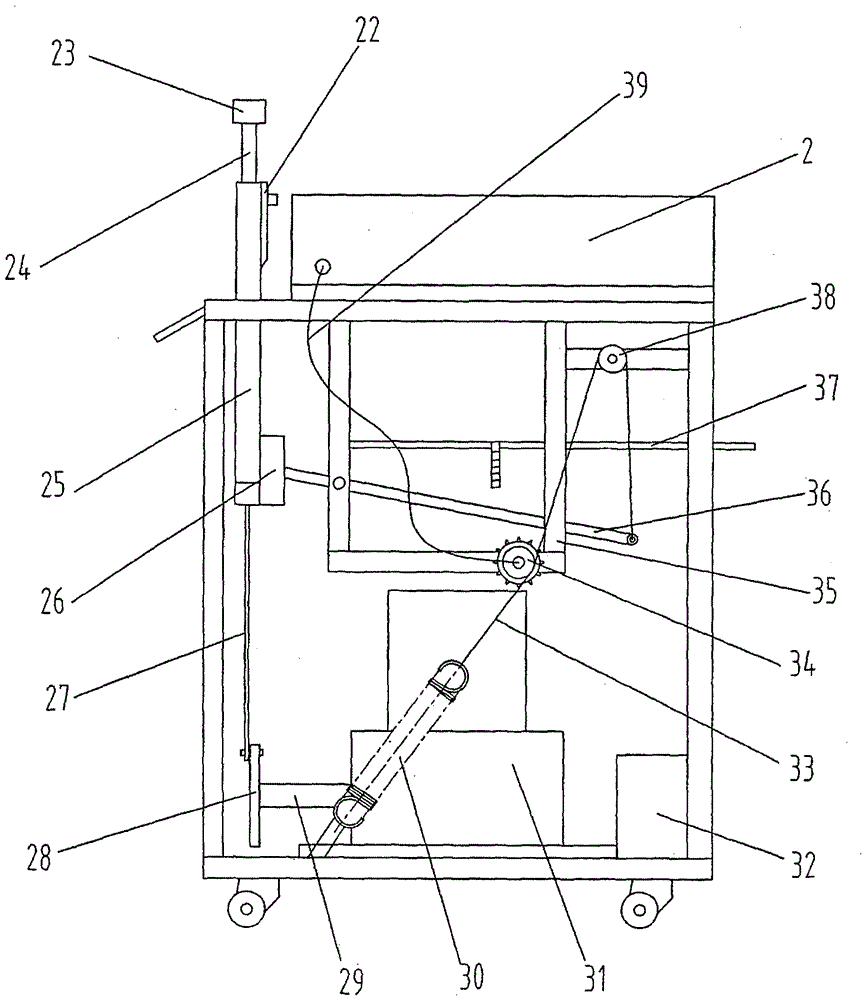

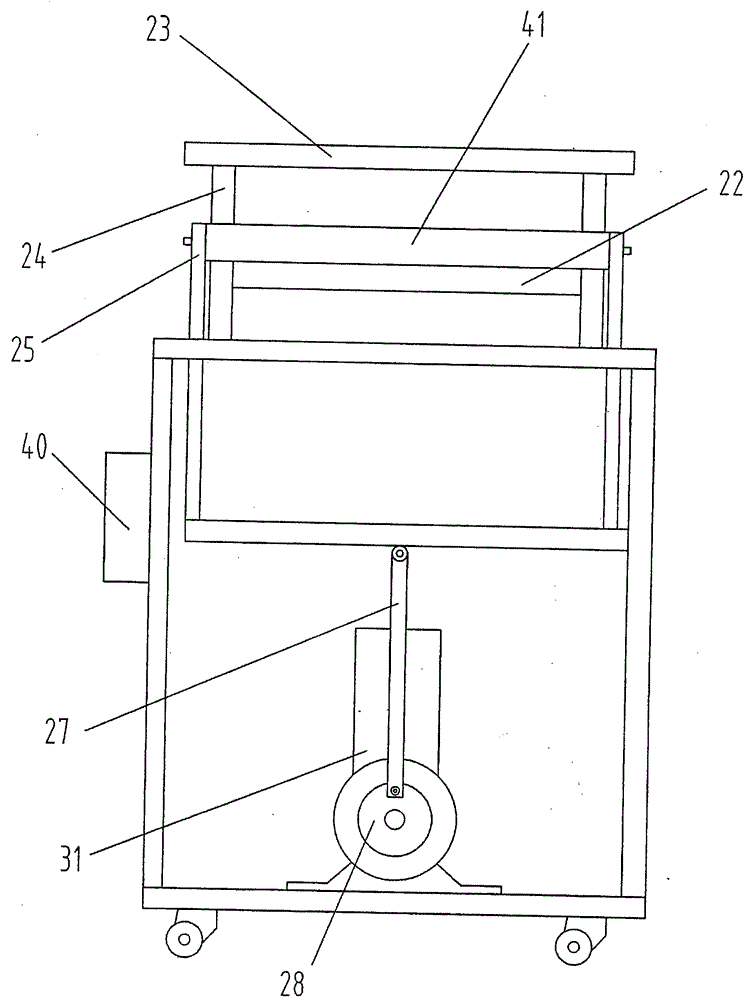

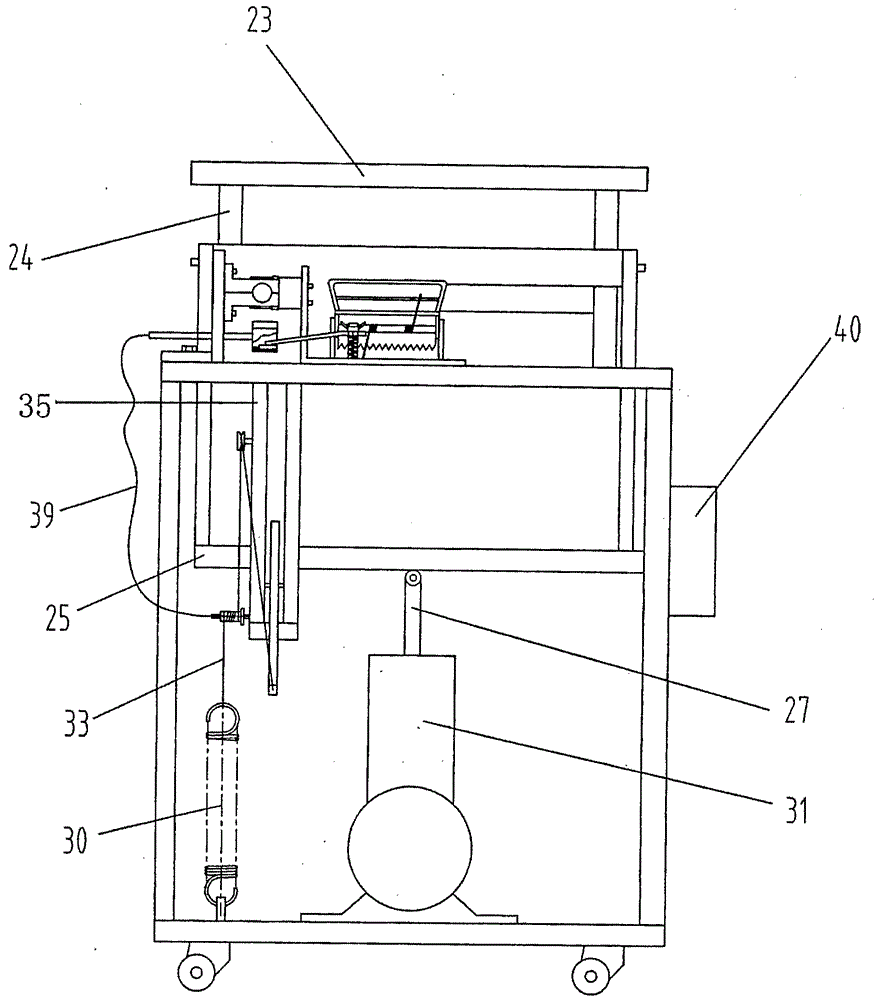

[0022] The present invention will be further described below in conjunction with embodiments and accompanying drawings.

[0023] Such as Figure 1-9 As shown, a bone cutting machine of the present invention includes a bone cutting machine frame 1, a motor reducer 31 arranged on the inner bottom plate of the frame, and two guide columns vertically arranged at the rear of the upper plate of the frame 24. A knife frame 41 with a bone cutting knife set on two guide columns, an automatic feeding device set on the upper surface of the bone cutting machine frame, connected to both ends of the knife frame and passing through the bone cutting machine frame The upper plate goes deep into the connecting rod frame 25 inside the frame, and one end is hinged at the middle part of the lower crossbar of the connecting rod frame, and the other end is eccentrically hinged with the outer surface of the runner 28 arranged on the output shaft 29 of the motor reducer 27; A hanger 35 is hoisted on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com