A kind of FD convenient oat compound rice and preparation method thereof

A production method and technology of oatmeal, applied in the functions of food ingredients, food science, applications, etc., can solve the problems of nutrient loss, long rehydration time, low rehydration rate, etc., and achieve rich nutrition, good taste, and safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Take 400g of naked oats after cleaning and removing impurities, and conduct a high-temperature instant enzyme inactivation at 130°C for 10s. After the oats are cooled, they will be balanced to the initial moisture content. Add water to moisten the oats for 3 hours, so that the moisture content after moistening is 9%, and then use the configuration The oat peeling machine with 60# grinding wheel rubs and peels the oats for 15 seconds. At this time, the peeling rate is 9%, and the rice yield is 77%. The crumbs are removed to obtain peeled oatmeal.

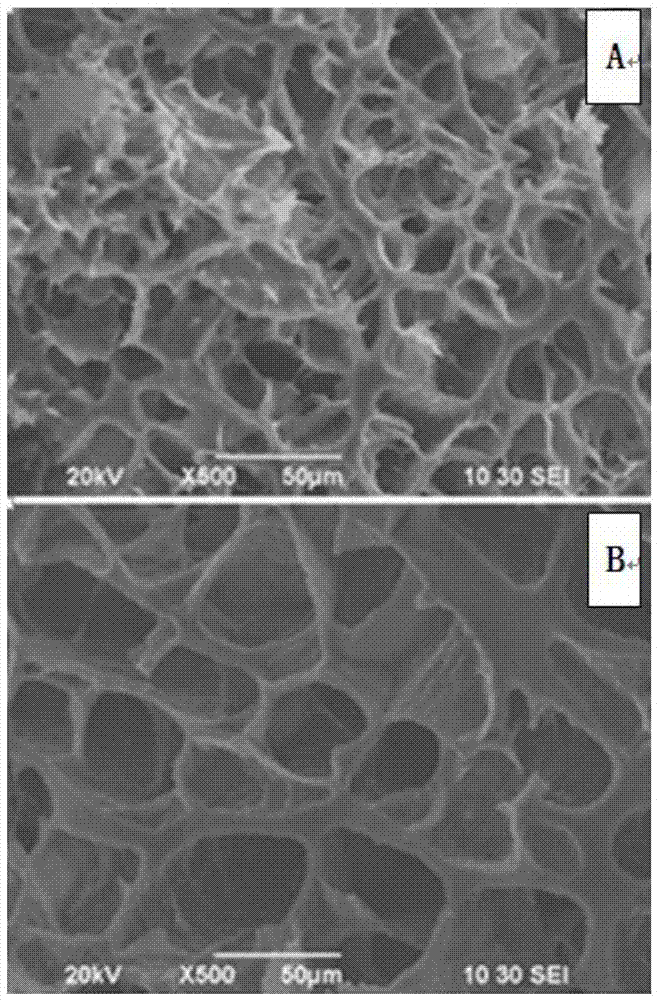

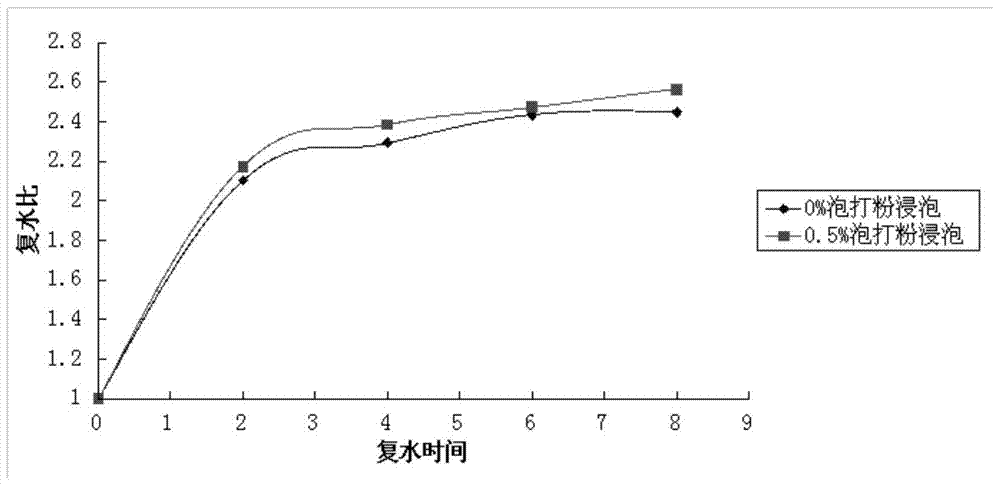

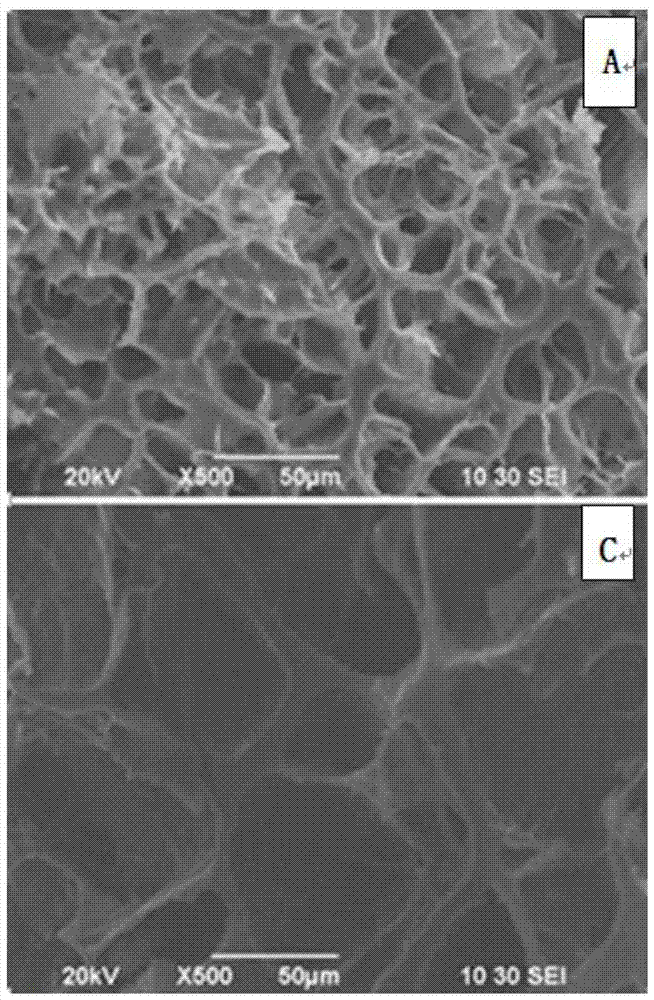

[0044] Weigh 300g of peeled oatmeal, mix it with 700g of japonica rice, soak it in 0.5% baking powder solution for 40min at 25°C, pour off the baking powder solution, add water (2000g) twice the weight of raw rice, and put it in a pressure cooker Cook for 15 minutes at a cooking temperature of 120°C. After cooling, disperse for 30 seconds in clear water twice the mass of raw rice. Filter out the clear water and blot the rema...

Embodiment 2

[0046] Take 400g of peeled oats after cleaning and removing impurities, and conduct a high-temperature instant enzyme inactivation at 135°C for 8s. After the oats are cooled, they will be balanced to the initial moisture content. Add water to moisten the oats for 3 hours, so that the moisture content after moistening is 10%, and then use the configuration The oat peeling machine with 60# grinding wheel rubs and peels the oats for 15 seconds. At this time, the peeling rate is 9.5%, and the rice yield is 76%. The crumbs are removed to obtain peeled oatmeal.

[0047]Weigh 300g of peeled oatmeal, mix it with 700g of japonica rice, soak it in 0.6% baking powder solution for 40min at 27°C, pour off the baking powder solution, add water (2000g) twice the weight of raw rice, and put it in a pressure cooker Cook for 15 minutes at a cooking temperature of 120°C. After cooling, disperse for 30 seconds in clear water twice the mass of raw rice. Filter out the clear water and blot the re...

Embodiment 3

[0049] Take 400g of peeled oats after cleaning and removing impurities, and conduct a high-temperature instant enzyme inactivation at 140°C for 6s. After the oats are cooled, they will be balanced to the initial moisture content. Add water to moisten the oats for 3 hours, so that the moisture content after moistening is 11%, and then use the configuration The oat peeling machine with 60# grinding wheel rubs and peels the oats for 15 seconds. At this time, the peeling rate is 10%, and the rice yield is 75%. The crumbs are removed to obtain peeled oatmeal.

[0050] Weigh 300g of peeled oatmeal, mix it with 700g of japonica rice, soak it in 0.7% baking powder solution for 40min at 29°C, pour off the baking powder solution, add water (2000g) twice the weight of raw rice, and put it in a pressure cooker Cook for 15 minutes at a cooking temperature of 120°C. After cooling, disperse for 30 seconds in clear water twice the mass of raw rice. Filter out the clear water and blot the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com