Three-channel microsphere screening chip and use method

A three-channel, chip technology, applied to chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of increased drying production costs, inconvenient screening, long filtration time, etc., to achieve convenient production Simple, Inexpensive, Professional Results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

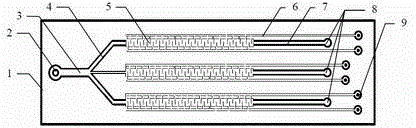

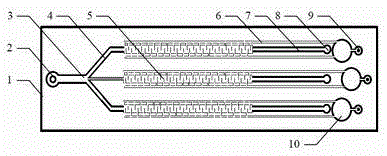

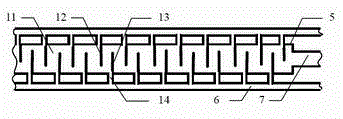

[0023] refer to Figure 1 to Figure 5 In the shape structure, the chip specification 1 is 3 pieces, and the channel width between the fences is 2 μm; the chip specification 2 is 3 pieces, and the channel width between the fences is 5 μm.

[0024] The operation steps are as follows: In the first step, prepare the sample solution pretreated with a large-scale chip, and the diameter of the microsphere is about 5 μm.

[0025] In the second step, 2 specifications of chips, 6 chips in total, close all the screening outlets 9, inject deionized water from the injection port 2, and open all the screening outlets 9 after the deionized water flows out from the sample outlet 8. Negative pressure at the screening outlet 9, drainage of deionized water, after all the screening outlets 9 have deionized water flowing out, close all the screening outlets 9, sample inlet 2, and sample outlet 8, and wait for use.

[0026] In the third step, first use the second chip with the largest specificatio...

Embodiment 2

[0029] refer to Figure 1 to Figure 5 In the shape structure, the size of the 3-chip chip is five, and the channel width between the fences is 20 μm; the size of the 2-chip chip is eleven, and the channel width between the fences is 50 μm.

[0030] The size of the 2-chip chip is 21, and the channel width between the fences is 100 μm.

[0031] According to the operation method of Example 1, from large to small, finally collect the screening samples collected from the screening outlet 9 of the 11-chip screening outlet of 3 specifications, and obtain microspheres with a particle size between ?50 μm and ?100 μm.

[0032] Finally, collect the screening samples collected by the screening outlet 9 of the screening outlet 9 of three specifications of five chips, and obtain microspheres with a particle size between -20 μm and -50 μm.

Embodiment 3

[0034] refer to Figure 1 to Figure 5 In the shape structure, the 4-piece chip size 6, the channel width between the fences is 25 μm; the 3-piece chip size 7, the channel width between the fences is 30 μm.

[0035]3 chip size 8, the channel width between the barriers is 35μm.

[0036] According to the operation method of Example 1, from large to small, finally collect the screening samples collected from the screening outlet 9 of the screening outlet 9 of 3-size seven chips, and obtain microspheres with a particle size of ?30 μm ~ ?35 μm.

[0037] Finally, collect the screening samples collected by the screening outlet 9 of the screening outlet 9 of 3 pieces of six chips, and obtain microspheres with a particle size of ?25 μm ~ ?30 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com