Rotary-vibrating and sieving device of nuclear fuel UO2 microspheres

A technology of nuclear fuel and vibrating screen, applied in the direction of filter screen, solid separation, grid, etc., can solve the problem that the screening device cannot be screened with microspheres, etc., to reduce the content of unqualified materials, improve the output rate, The effect of increasing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

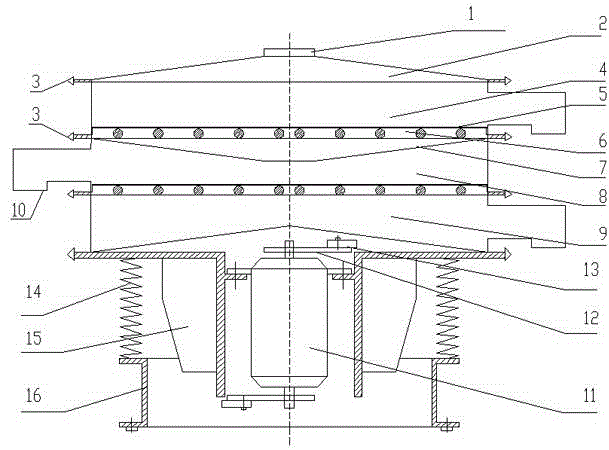

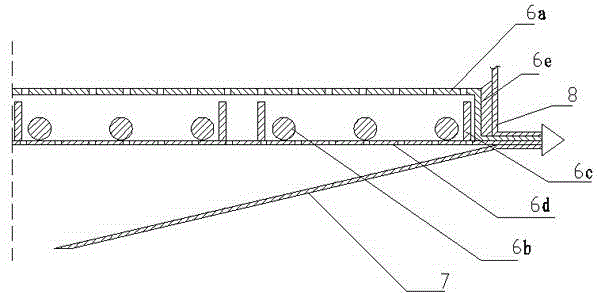

[0024] Such as Figures 1 to 4 The structural schematic diagram shown, the nuclear fuel UO of the present invention 2 The microsphere rotary vibration screening device includes a base 16 fixed on the ground, a vibrating body 15 is installed on the base 16, a rotating motor 11 is installed in the vibrating body 15, and on the two output shafts of the rotating motor 11, each A vibrating arm 12 is installed, and an arc-shaped counterweight 13 is installed on the vibrating arm 12. The arc-shaped counterweight 13 is a semicircular steel plate structure, and two asymmetrical position adjustment holes 17 are arranged on it. Used to produce different vibration amplitudes and vibration strengths, the lower screen frame 9, the middle screen frame 8, the upper screen frame 4, and the dust cover 2 are successively stacked on the vibrating body 15, and a feeding material is arranged on the top of the dust cover 2. Port 1, between the lower screen frame 9 and the middle screen frame 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com