Pressurizing mechanism of hydraulic vulcanizing machine

A technology for pressurizing mechanism and vulcanizing machine, which is applied in the field of pressurizing mechanism and hydraulic vulcanizing machine, which can solve the problems of affecting work efficiency, small space occupation, and narrow space of vulcanizing machine, so as to improve disassembly and assembly efficiency and efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

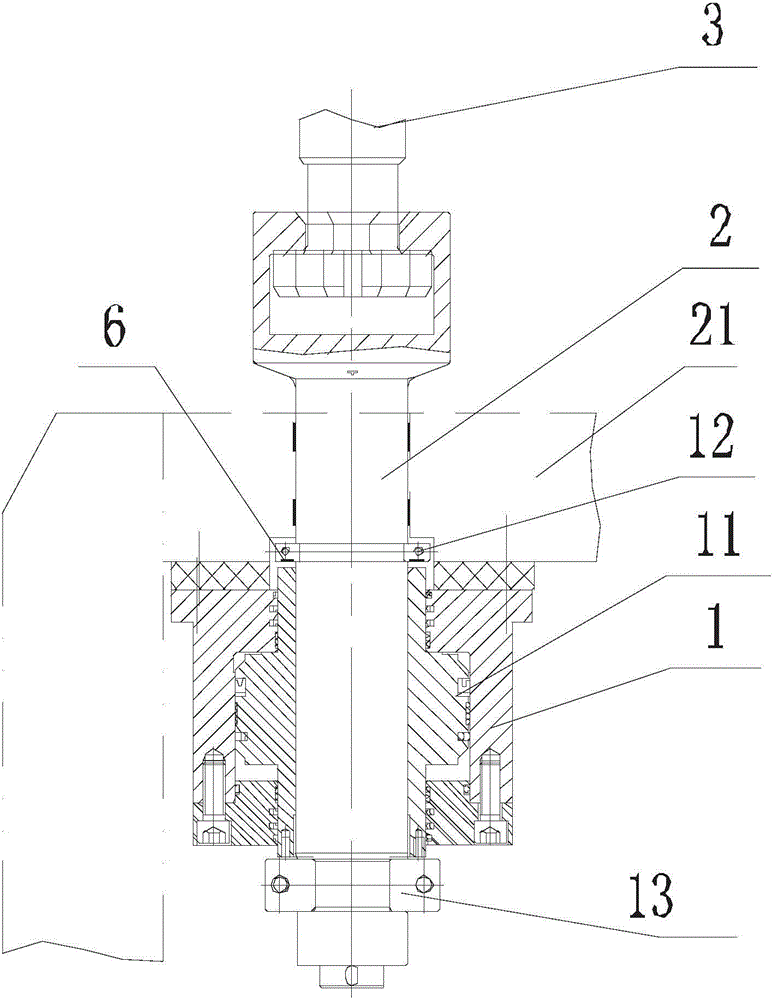

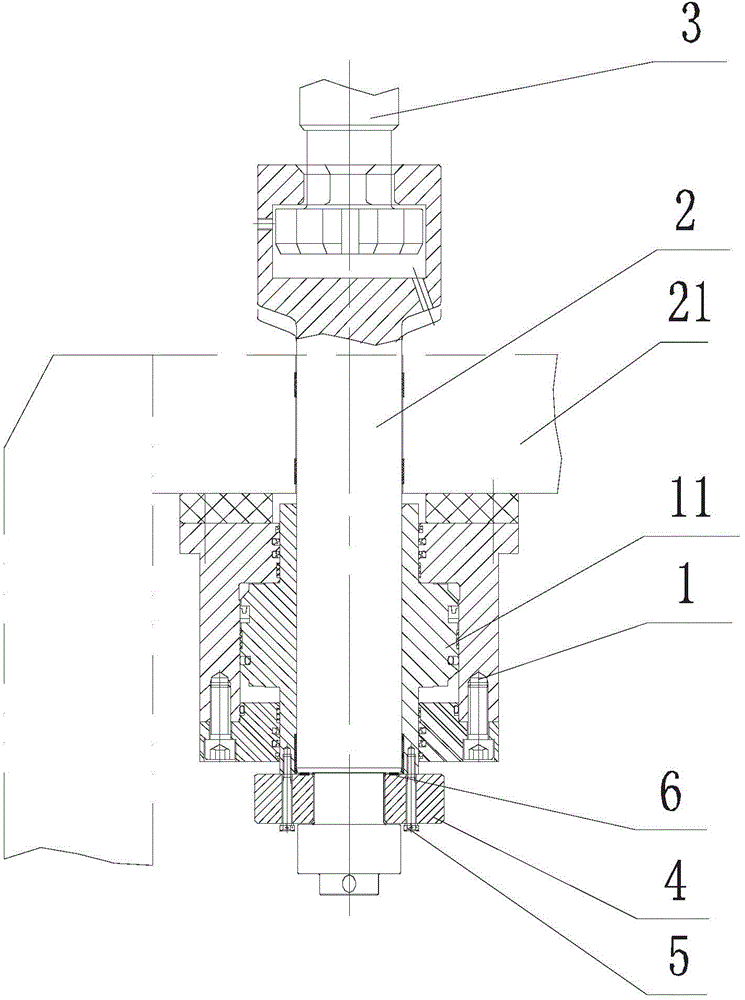

[0019] In order to achieve the purpose of the present invention, as figure 2 As shown, in some embodiments of the pressurizing mechanism of the hydraulic vulcanizer of the present invention, a hollow cylinder 1 is included, the piston 11 of which is sleeved on the lower rod 2 of the hydraulic vulcanizer, and the lower rod 2 is connected with the upper rod 3. The upper end of the piston 11 approaches or touches the base 21 of the hydraulic vulcanizer without hindrance, that is, it is close to the base 21 or directly contacts the base 21. The lower end of the piston 11 is provided with a snap ring 4, and the snap ring 4 is fixedly sleeved on the pull-down rod 13. , while the snap ring 4 is also fixedly connected to the piston 11 by screwing.

[0020] Compared with the structure in the background technology, this mechanism cancels the upper sn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com