Gravure printing plate, manufacturing method thereof, gravure printing machine, and manufacturing method for laminated ceramic electronic component

A manufacturing method and gravure printing technology, applied in the direction of electrical components, multilayer capacitors, printing, etc., can solve the problems of reduced opening area, easy residual conductive paste, narrowing of the internal electrode area, etc., to reduce the degree of unevenness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

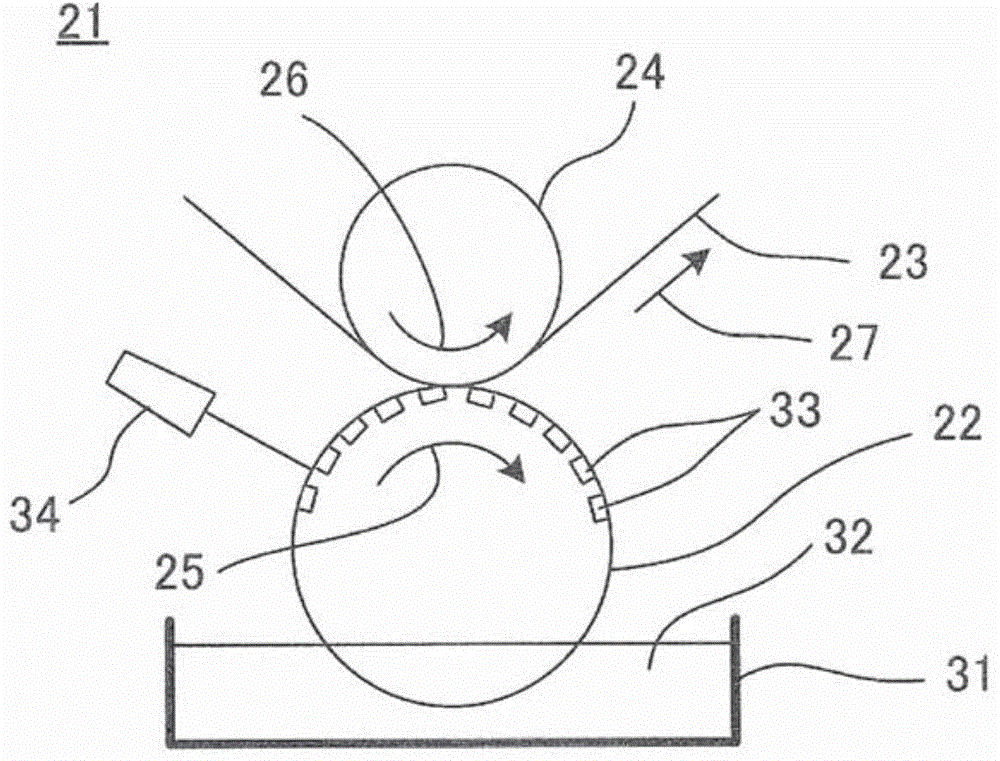

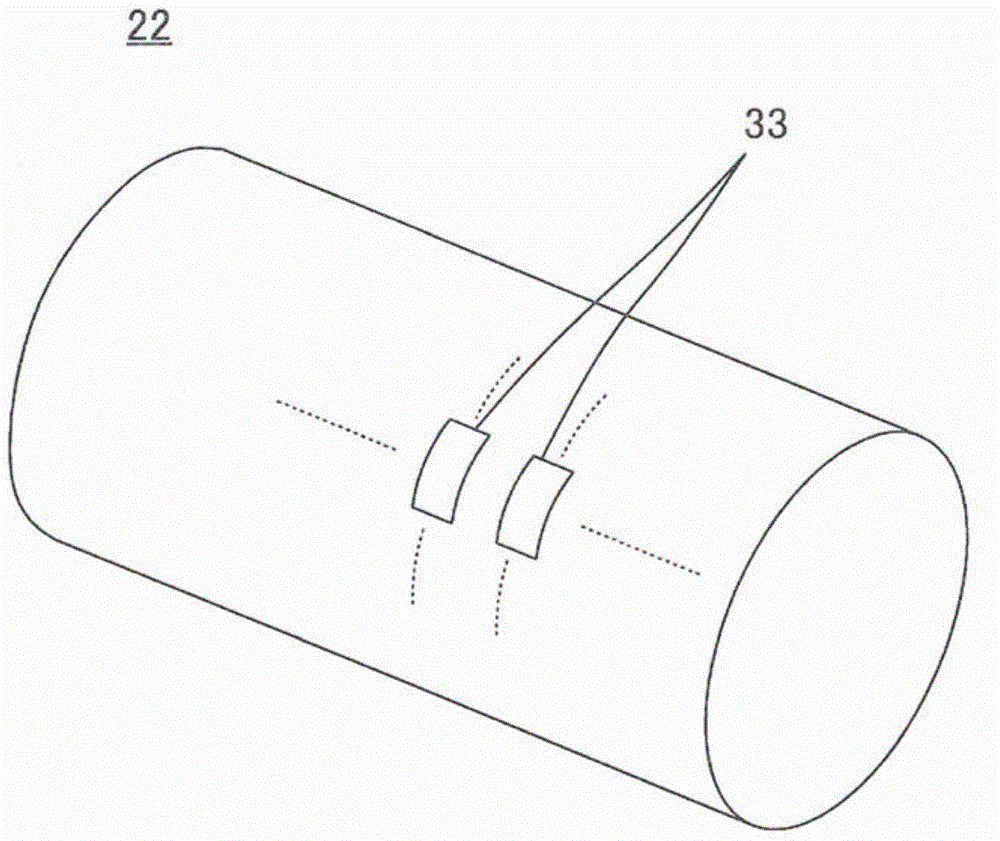

[0068] Refer below figure 1 , the gravure printing machine 21 including the gravure cylinder 22 as the gravure printing plate according to the present invention will be briefly described.

[0069] The gravure printing machine 21 includes a gravure cylinder 22 and an impression cylinder 24 facing the gravure cylinder 22 with a sheet-like object 23 interposed therebetween. The gravure cylinder 22 and the impression cylinder 24 rotate in the directions of arrows 25 and 26 respectively, thereby conveying the object to be printed 23 in the direction of the arrow 27 . In addition, in the case of a gravure printing press, a gravure printing press without an impression cylinder may also be used.

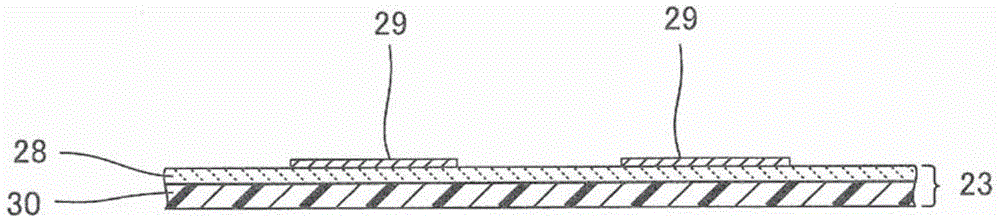

[0070] The gravure printing machine 21 is used to manufacture multilayer ceramic electronic components such as multilayer ceramic capacitors. More specifically, the gravure printing machine 21 is used to form a paste film on the printed object 23 by gravure printing, and this paste film w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com