A near-net additive manufacturing method for electron beam fuses

A manufacturing method and electron beam technology, applied in the field of additive manufacturing, can solve problems such as the inability to balance the forming surface quality and forming efficiency, the inability to realize near-net additive manufacturing of metal materials, and the rough surface of the stacked layer, so as to improve the aesthetics, The effect of accurate external dimensions and small machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

[0022] First of all, it should be explained that the words "thick" and "thin" mentioned in this embodiment are relative concepts, rather than a certain specific size. These words are used only to illustrate the technical solution of the present invention more clearly and clearly. , and are not intended to limit the protection scope of the present invention.

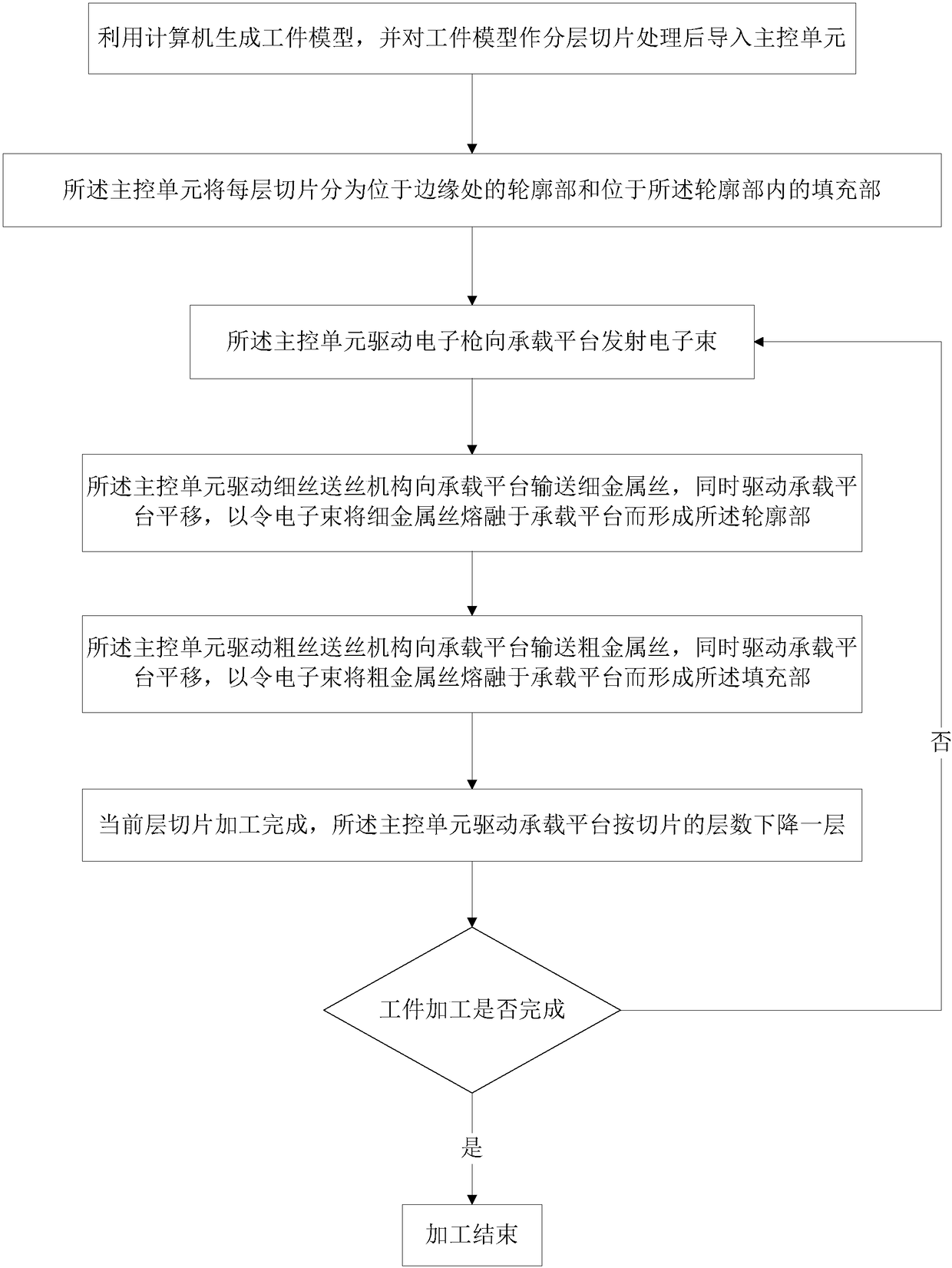

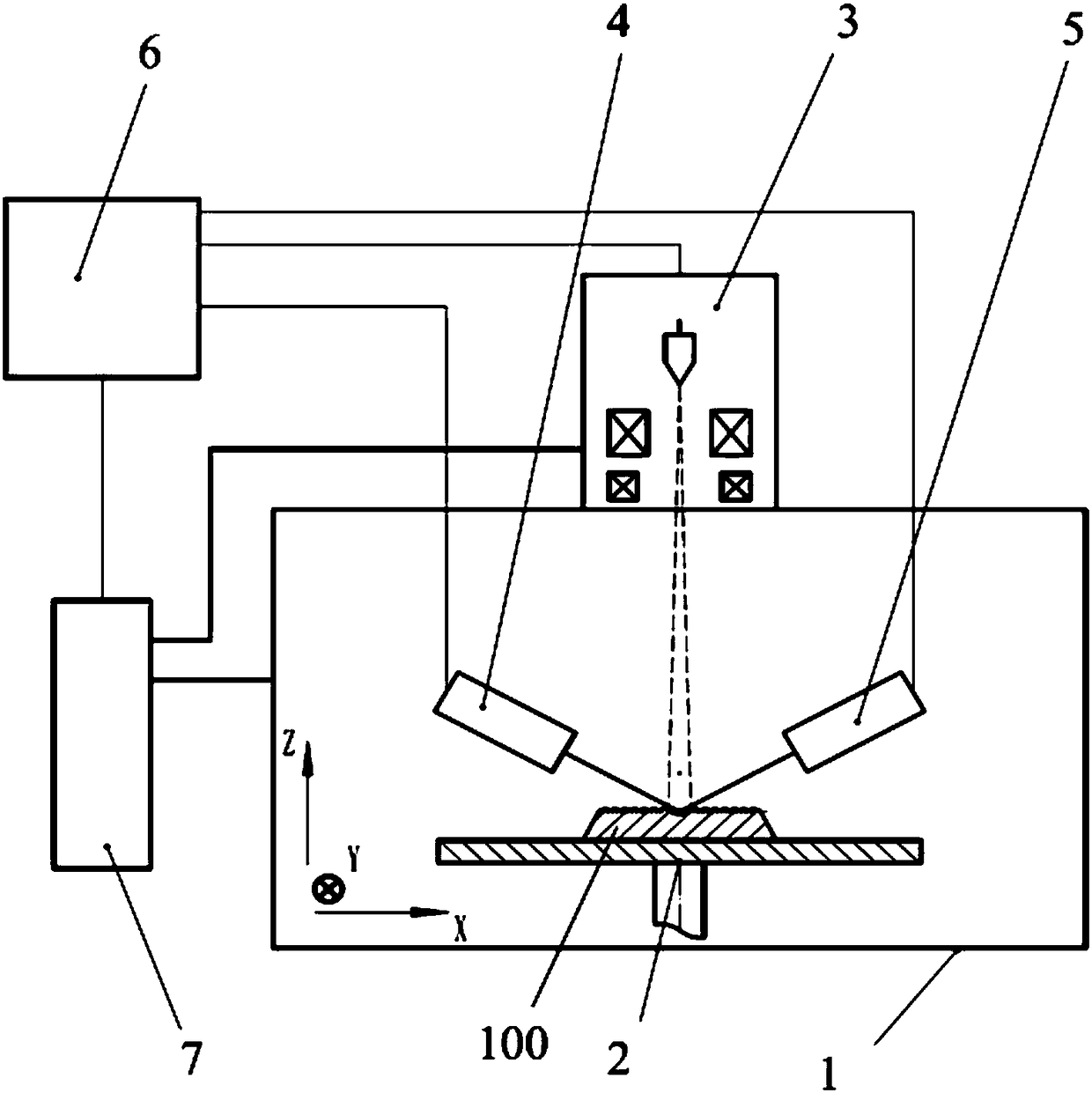

[0023] The invention discloses a near-net additive manufacturing method for an electron beam fuse, which combines Figure 1 to Figure 3 As shown, the method is realized based on a device, and the device includes a vacuum chamber 1, a carrying platform 2, an electron gun 3, a thin wire feeding mechanism 4, a thick wire feeding mechanism 5 and a main control unit 6, Described method comprises the following steps:

[0024] Step S1, using a computer to generate a workpiece model, and importing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com