A pressure-resistant sealed cabin suitable for underwater sports

A technology of pressure-resistant sealing and movement, which is applied in underwater operation equipment, transportation and packaging, ships, etc. It can solve the problems of unreliable sealing design, lack of connection form of sealing connection, insufficient connection precision, etc., and solve the problem of sealing design , Improving the effect of connection accuracy and sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

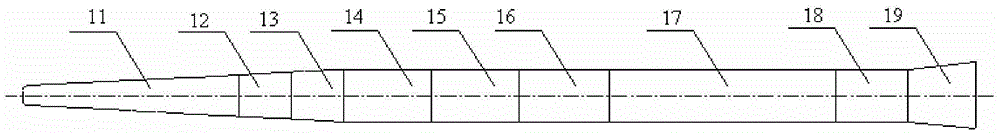

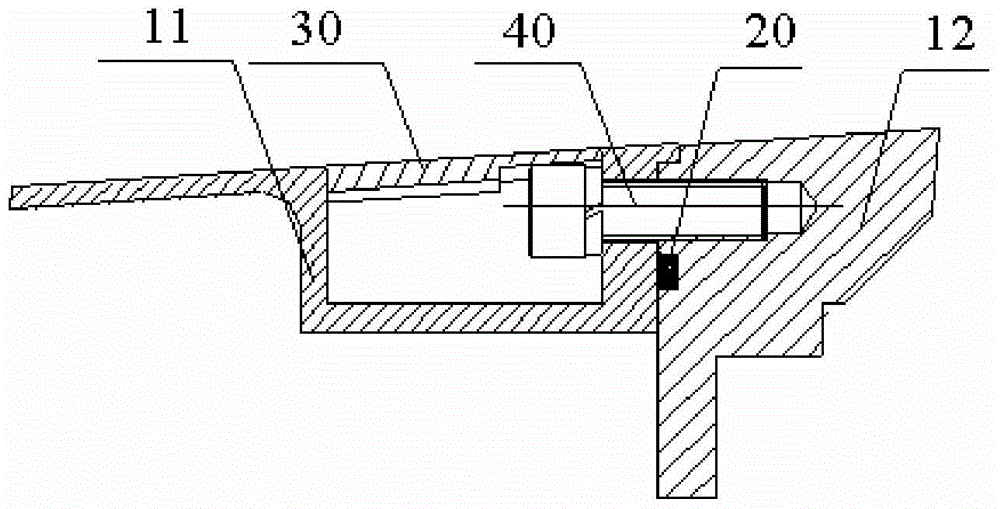

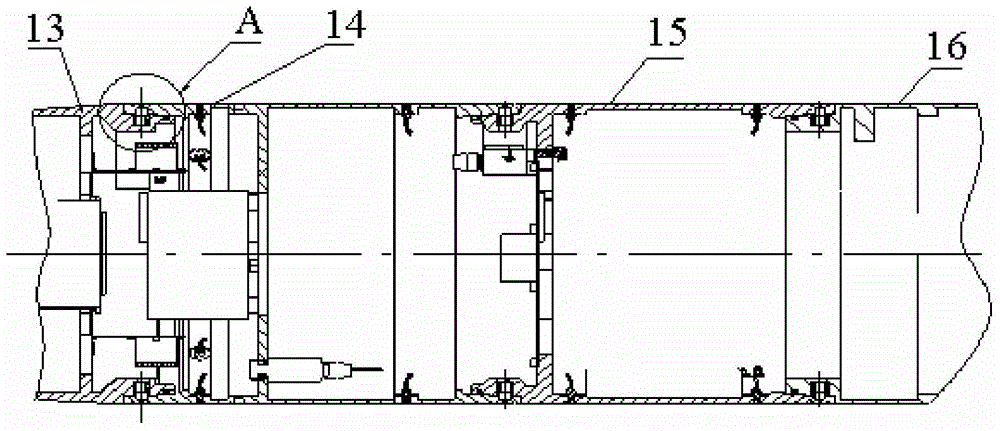

[0020] The pressure-resistant airtight chamber designed by the present invention, which is suitable for underwater high-speed movement, consists of 3 conical chambers and 6 column chambers arranged in series, wherein the conical section and the conical section are designed to be sealed and connected with the axial end face, which can realize effective sealing and load bearing. Cone section and column section, column section and column section adopt radial seal connection design and embedded steel sleeve to realize load transmission and sealing, which can effectively bear force and have the function of repeated disassembly.

[0021] The applicable environment of the pressure-resistant airtight cabin of the present invention is that the pressure-resistant cabin is under a pressure of 1 atm (atmospheric pressure), works uninterruptedly underwater for no less than 2 hours, and has a maximum movement speed of 90m / s, adapting to changes in the underwater height of 5m to 40m. Under su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com