Stock bin arch-breaking device

A silo and arch breaking technology, which is applied in packaging, transportation and packaging, containers, etc., to achieve the effect of simple and practical structure, damage prevention, and unlimited arch breaking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

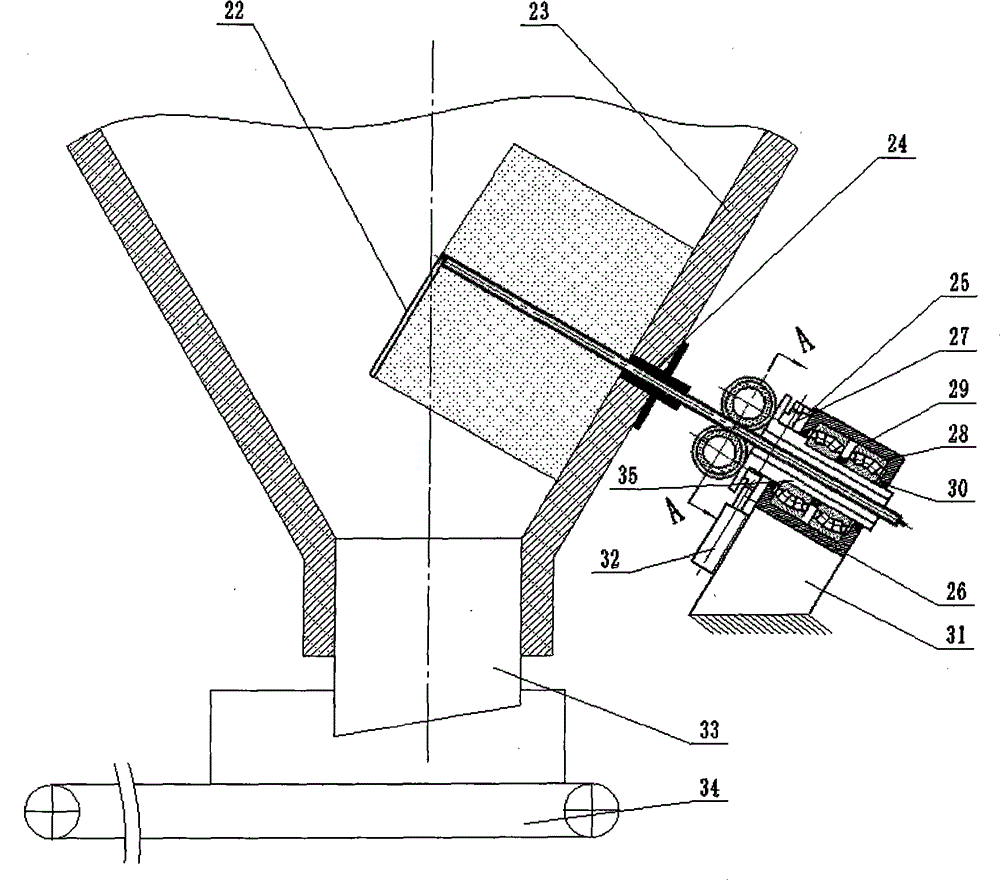

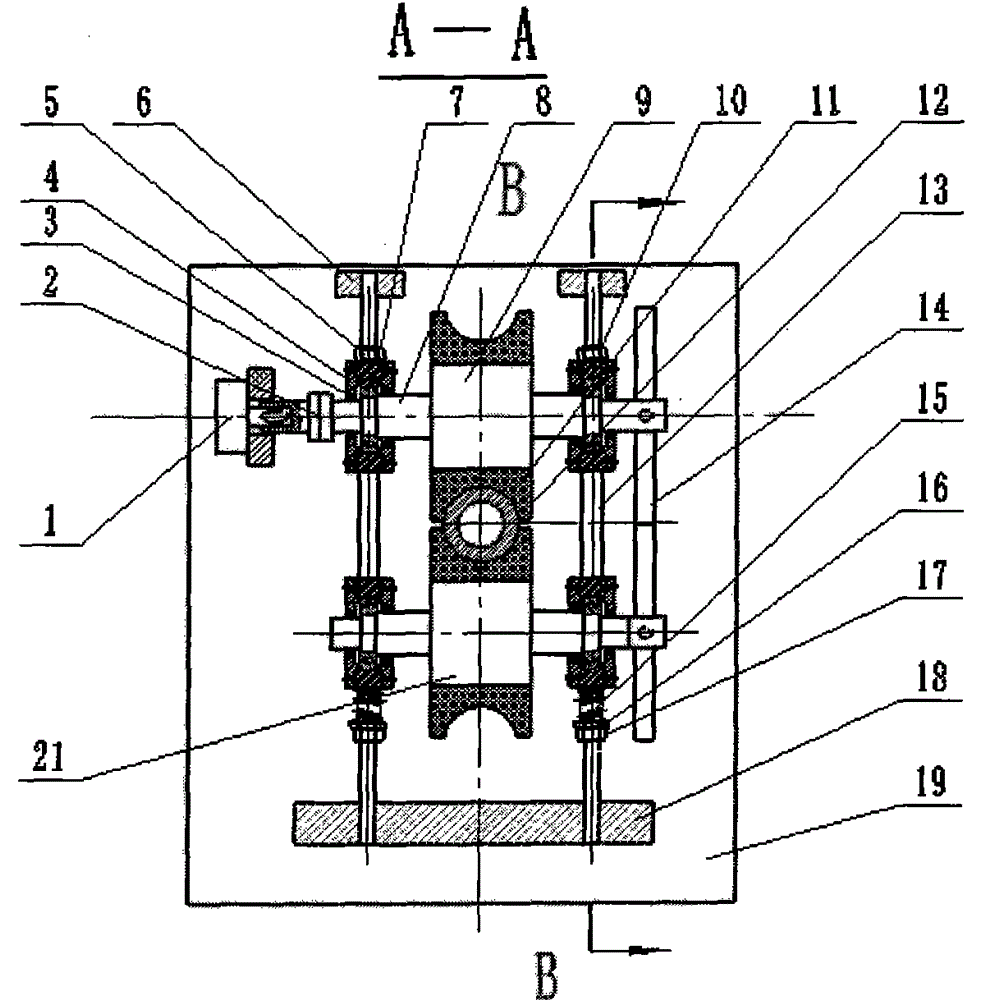

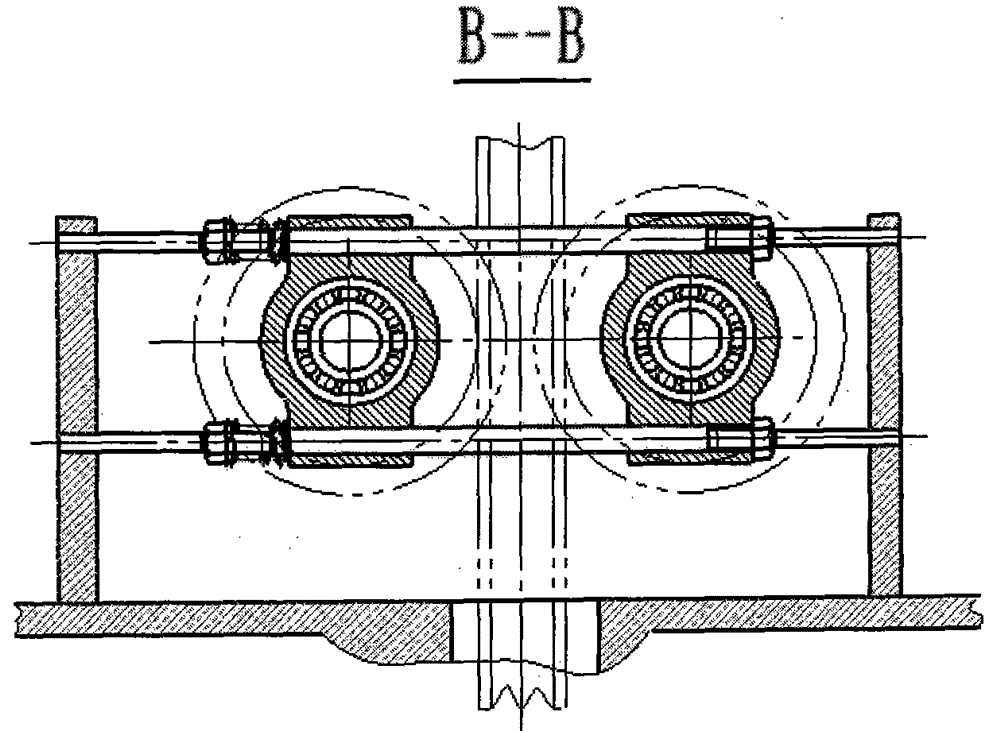

[0035] Embodiment one: see figure 1 , figure 2 , image 3, the guide sleeve 24 is installed on the silo wall of the silo 23, and the distance-adding rod 22 is hinged at the end of the arch-breaking rod 12. One end of the arch-breaking rod is installed in the guide sleeve, and the other end is clamped in the clamp Between the holding wheel 9 and the outer edge polymer elastic groove 11 of the afterburner clamping wheel 21, the left and right connecting plates 6, 18 are connected on the wheel seat 19, and the two ends of the circular guide post 13 are connected and fastened on the left and right connecting plates , the shaft seat 10 is installed in series on the circular guide post, and is driven to rotate by the rotary drive device 1 through the wheel shaft 8 and the coupling 2 . The two clamping wheels are installed on the shaft seats at both ends through the wheel shaft and the bearing 7, and the shaft seats of the stressed clamping wheels are positioned on the circular gu...

Embodiment 2

[0037] Embodiment two: see Figure 4 , The difference between this embodiment and Embodiment 1 is that the clamping force cylinder 20 is used to drive the shaft seat to move on the circular guide post so that the clamping wheel can generate clamping force on the broken arch bar. The clamping force of this structure is easy to adjust, and the adjustment range is large, and the clamping force can be released at any time by releasing the pressure of the oil cylinder.

Embodiment 3

[0038] Embodiment three: see Figure 5 , Figure 6 , in this embodiment, the wheel seat 10 is directly installed on the inner hinge seat 39 of the spherical hinge, and the outer hinge seat 38 matched with the inner hinge seat is installed on the silo wall through the connecting anchor rod 36, and the inner hinge seat A central hole is provided on the hole, and a guide ring 42 is installed in the hole, and the broken arch rod passes through the guide ring and enters in the feed bin. The other end of the broken arch rod is equipped with a swing ring 43 which is equivalent to a hinge sleeve and has an inner diameter greater than the outer diameter of the broken arch rod. The swing ring is connected with two swing cylinders 41 distributed at an angle of 90°, and the swing cylinder is hinged on the foundation and supported by the oil cylinder backing plate 40, an annular flexible gasket 37 is connected between the inner gallows and the outer hinge seat to adapt to the swing of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com