Circular closed modular unit body

A closed and modular technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of cumbersome parts installation, long construction period, weak wind resistance, etc., to achieve convenient transportation and installation, shorten construction time, reduce wind resistance The effect of a small coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

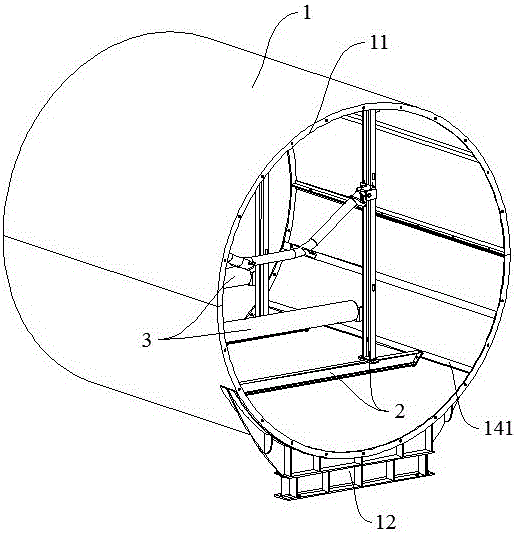

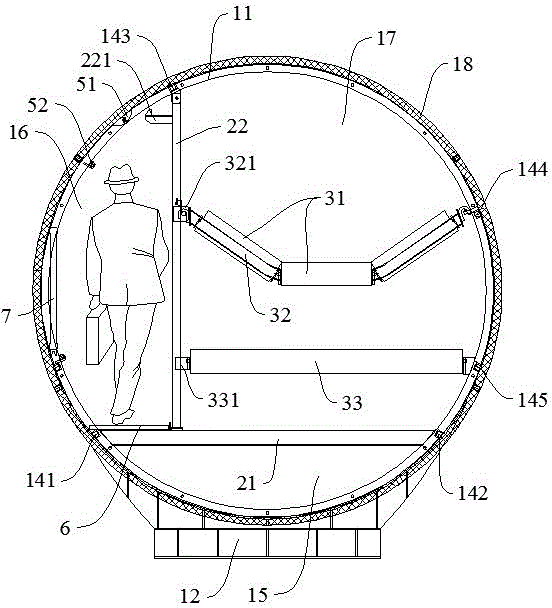

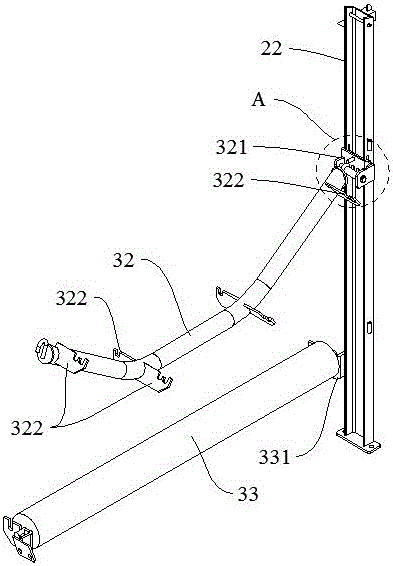

[0026] Such as Figure 1 to Figure 5 As shown, a circular closed modular unit body, including: shell 1, bracket 2, idler mechanism 3, lighting system, floor 6; wherein, shell 1 is cylindrical, with flange protrusions at both ends flange 11 structure, and the flange flange 11 extends to the inside of the shell 1, the flange flange 11 is used for the connection between the body of the circular closed modular unit, that is, the two circular closed modules can be connected by bolts The flange flanges 11 of the chemical unit body are connected together, such as Figure 5 ; A base 12 is fixed on the outer wall close to one end of the housing 1, and the base 12 is used to connect and fix with the support mechanism 13 supporting the circular closed modular unit body; Strip-shaped profile, the two ends of the profile are fixed to the aforementioned flange flange 11 to enhance the strength of the flange flange 11 and the profile itself, the bracket 2 is erected in the shell 1 by connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com