Full-automatic bearing feeder

A feeding device, fully automatic technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increasing employee workload, occupying site space, inconvenient adjustment, etc., to reduce equipment investment costs and reduce on-site The effect of taking up space and reducing the workload of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

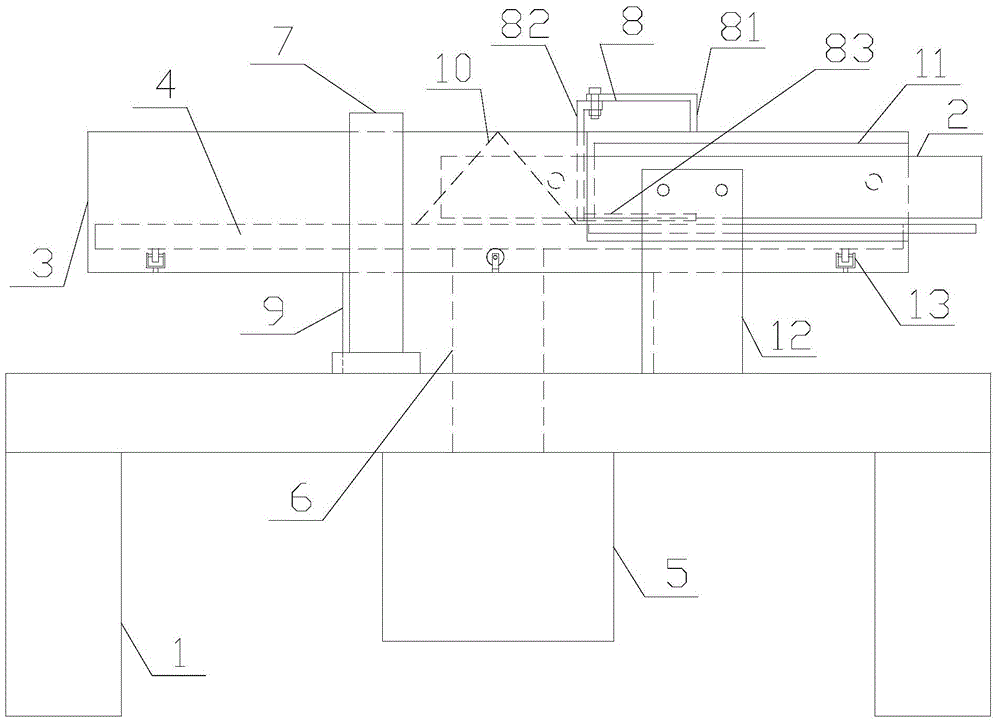

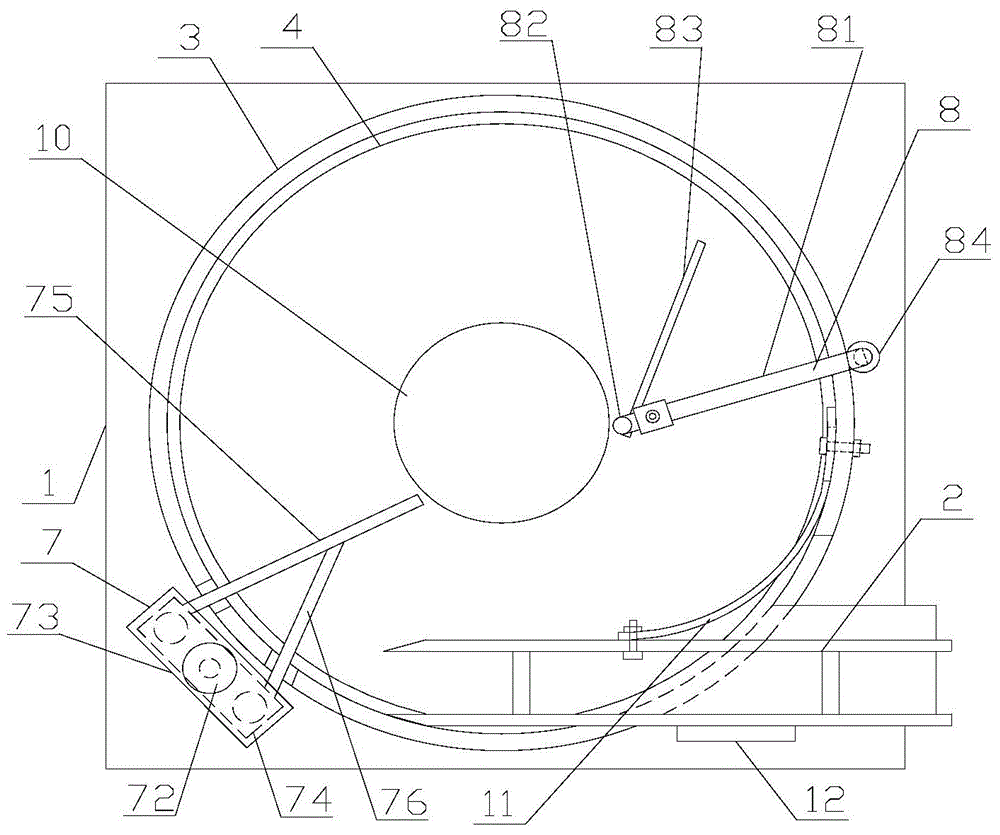

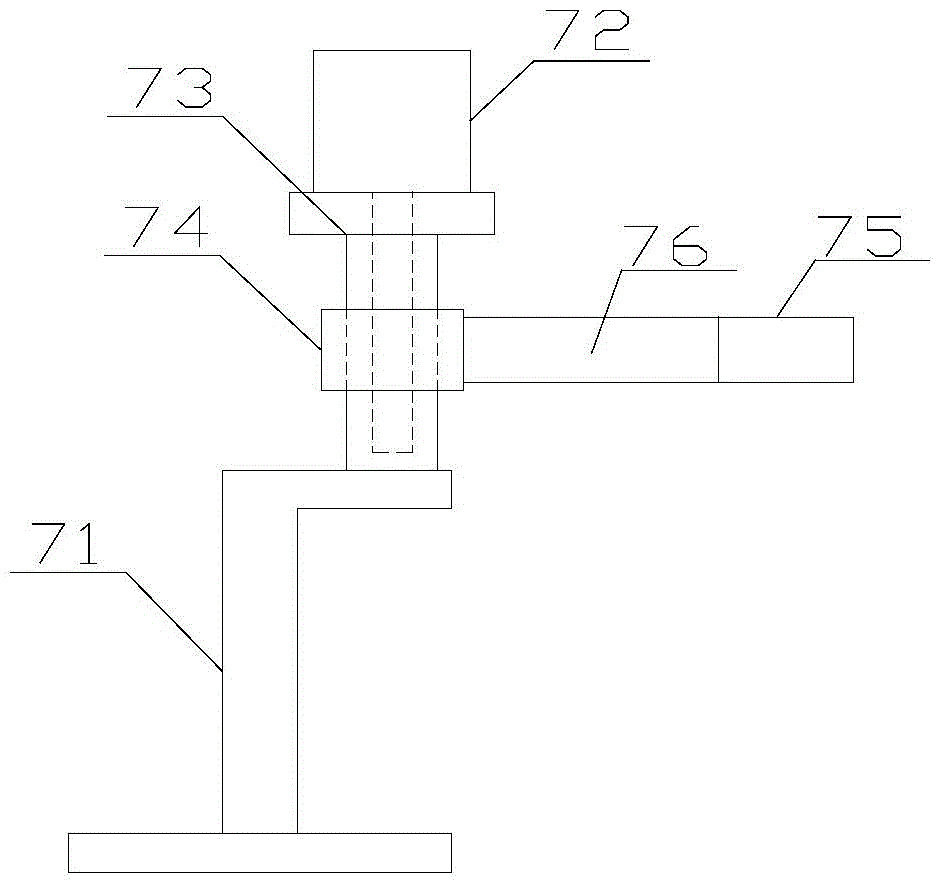

[0021] refer to figure 1 , figure 2 , image 3 and Figure 4 , a fully automatic bearing feeding device of the present invention, comprising a frame body 1, a discharge port 2, a cylinder body 3, a turntable 4, a reduction motor 5, a rotating shaft 6, an automatic lifting baffle mechanism 7 and a guide mechanism 8, the frame The platform of the body 1 is provided with a mounting seat 9 and an automatic lifting baffle mechanism 7, the mounting seat 9 is provided with a cylindrical body 3, the mounting seat 9 is installed with the rotating shaft 6, and the upper end of the rotating shaft 6 is provided There is a turntable 4, and the center of the turntable 4 is provided with a protrusion 10, and a reduction motor 5 is provided under the platform of the frame body 1, and the output shaft of the reduction motor 5 is fixedly connected with the lower end of the rotation shaft 6, and the cylinder The gap of the body 3 is provided with a discharge port 2, and a baffle 11 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com