Method and device for sensing signals for starting and stopping control of conveyor

A technology of signal induction and start-stop control, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of transmission equipment damage, high implementation cost, and difficulty in identifying the conveyed objects, so as to achieve convenient maintenance and avoidance The effect of false signals and low implementation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

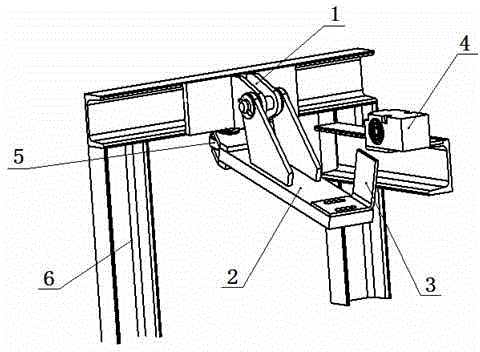

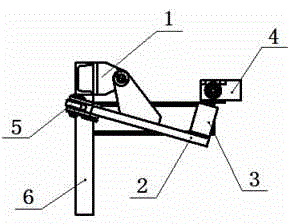

[0012] Embodiment of the present invention: it is to install a rotating bracket that can be pushed by the conveying material above the tail of the conveyor belt of the conveyor, install an induction plate at the end of the rotating bracket, and install a signal sensor that is used in conjunction with the induction plate above the rotating bracket. switch. When the conveyed object moves to the end of the conveyor belt, push the tail end of the rotating bracket to lift up, the induction plate enters the sensing range of the signal induction switch, and the signal induction switch controls the conveyor to stop; when the conveyed object leaves the conveyor belt, the tail end of the rotating bracket will Falling due to gravity, the induction plate is out of the sensing range of the signal induction switch, and the signal induction switch controls the conveyor to start.

[0013] A kind of device that adopts signal induction method of the present invention is constituted like this: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com