Liquid level control switch device and control circuit

A switching device, liquid level control technology, applied in liquid level control, measuring device, control/regulation system, etc., can solve the problems of electrolytic corrosion of induction electrodes, control circuit error signals, inconvenient electrode cleaning, etc., to avoid error signals , cost reduction, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0038] Embodiment 1 Liquid level control switch device.

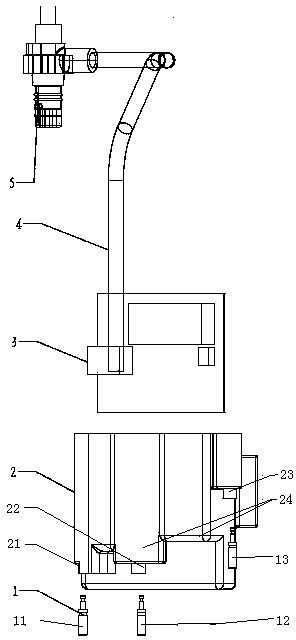

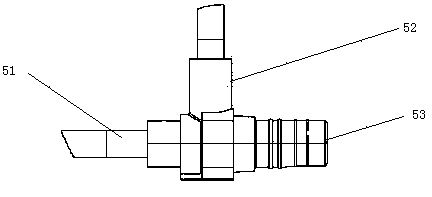

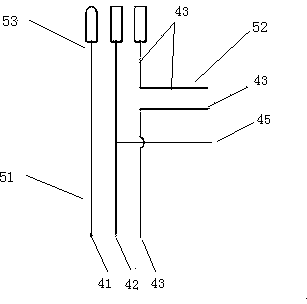

[0039] like Figure 1-Figure 3 As shown, a liquid level control switch device of the present invention includes a liquid level sensor, a contactor and a T-shaped joint 5 . The liquid level sensor includes a liquid level electrode 1, a casing 2, a control circuit board 3 and a power lead 4, the casing 2 is a cavity with an upper opening formed by a bottom surface and a side wall, and the control circuit board 3 is sealed and installed in the casing 2 One side of the lower part of the housing 2 is provided with the first installation hole 21, the second installation hole 22 and the third installation hole 23 for installing the liquid level electrode, and the liquid level electrode 1 for sensing the liquid level includes a The first electrode 11 for position sensing, the second electrode 12 for low liquid level sensing and the third electrode 13 for common terminal connection, the first electrode 11, the second electrode ...

Embodiment approach 2

[0049] Embodiment 2 Control Circuit

[0050] like Figure 5 and Image 6 As shown, the present invention provides a control circuit of a liquid level control switch device, the main design points of which are: comprising a first operational amplifier U2A, a first voltage comparator U1A, a second operational amplifier U2B, a second voltage comparator U1B, a micro The processor U3, the transistor Q1 and the step-down power supply U4. In order to clearly describe the principle and connection relationship of the control circuit of the present invention, in this example, the hardware components mainly adopt LM358 operational amplifier chip, LM393 voltage comparator chip and PIC12F509T microprocessor chip. The LM358 operational amplifier chip constitutes the first operational amplifier U2A and the second operational amplifier U2B, the LM393 voltage comparator chip constitutes the first voltage comparator U1A and the second voltage comparator U1B, and the PIC12F509T microprocessor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com