Collection device for plastic straws

A technology for collecting devices and straws, which is applied in the field of plastic straw processing equipment, and can solve the problems of low efficiency of plastic straws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0017] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

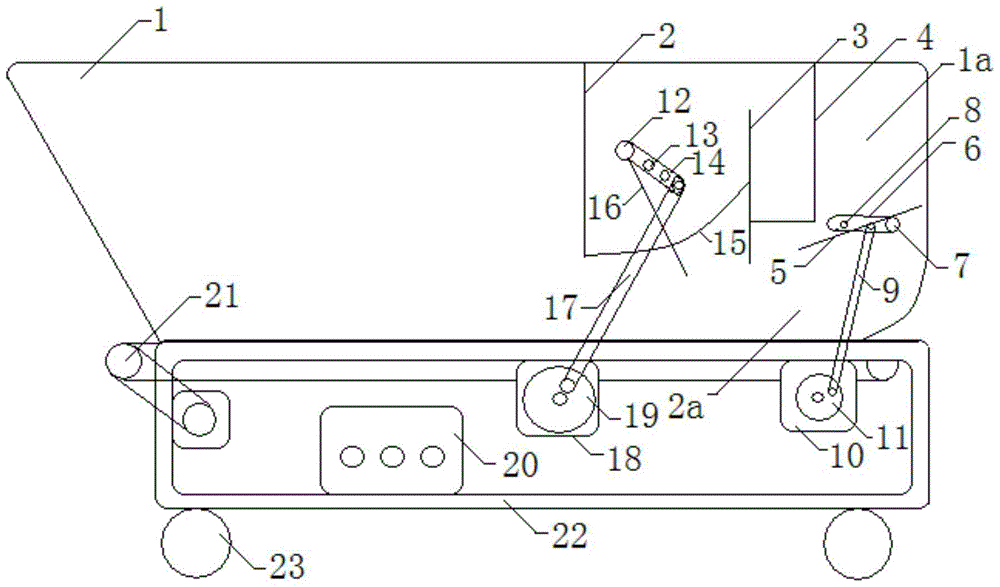

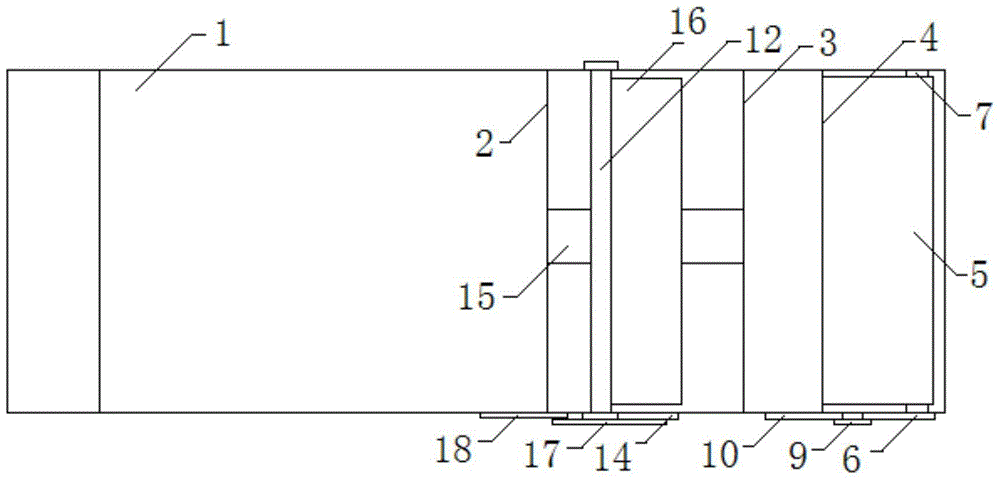

[0018] Such as Figure 1 to Figure 2 As shown, a collection device for plastic straws according to a specific embodiment of the present invention includes: a collection box 1, a first baffle 4, a second baffle 3, a third baffle 2, a blocking sheet 5, and a vibration mechanism , scraper mechanism, controller 20 and support wheel 23, the width of collection box 1 is slightly wider than the length of plastic straw, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com