Fabric drum ironing compacting machine

A technology of ironing compactor and fabric reel, which is applied in the direction of textiles and papermaking, fabric surface trimming, etc., which can solve the problems that the fabric is not smooth enough and affects the beauty of the fabric, and achieves the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

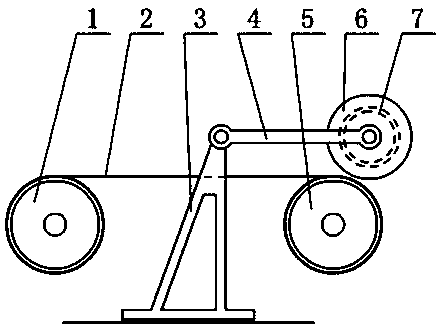

[0011] The present invention is to carry out some improvements on the original equipment. The support 3 is made of a steel plate with a thickness of 16 mm. The number of the support 3 is 2 pieces. The connecting rod 4 is made of a steel plate with a thickness of 20 mm. The number of solid stick 6 and connecting rod 4 is 2 pieces. The compacting stick 6 is made of high-quality steel and has a diameter of 200mm. , the connecting rod 4 is installed on both sides of the compacting rod 6.

[0012] To sum up, since the present invention installs the compacting stick on the top of the finished fabric stick, the efficiency and product quality are greatly improved in the garment manufacturing and processing, and the labor intensity of the workers is reduced at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com