Polymer spraying mortar and preparation method thereof

A technology of polymer and plastic spraying, applied in the field of artificial landscaping materials, can solve the problems of insufficient bonding strength, insufficient pumping, poor corrosion protection of steel structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention mainly discloses a polymer spray mortar and a preparation method thereof. The basic materials and preparation methods used therein should be well-known to those skilled in the relevant technical fields unless otherwise specified. Therefore, the following description will not refer to the mortar The ingredients are fully described and explained first.

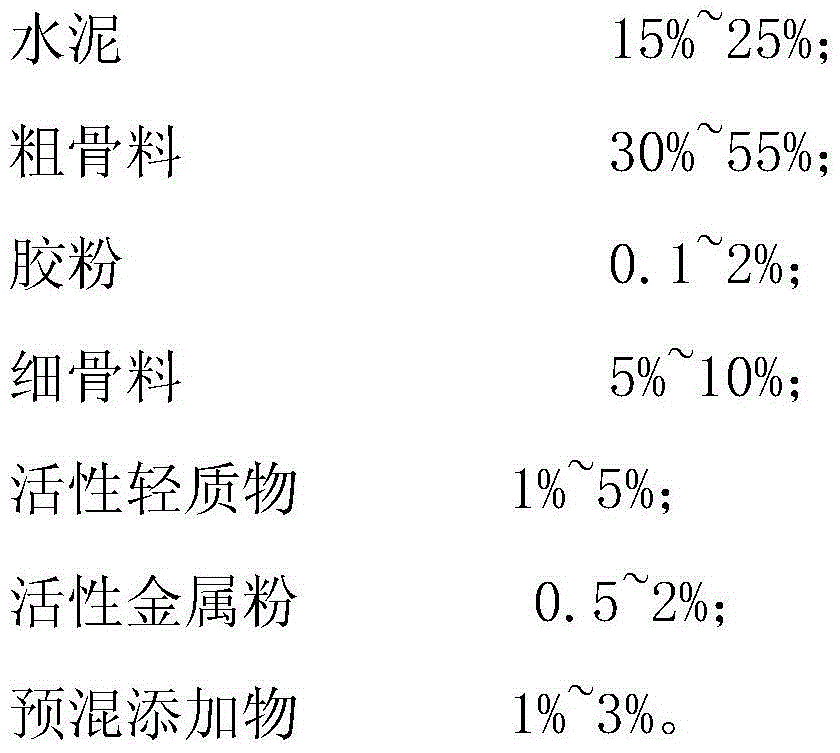

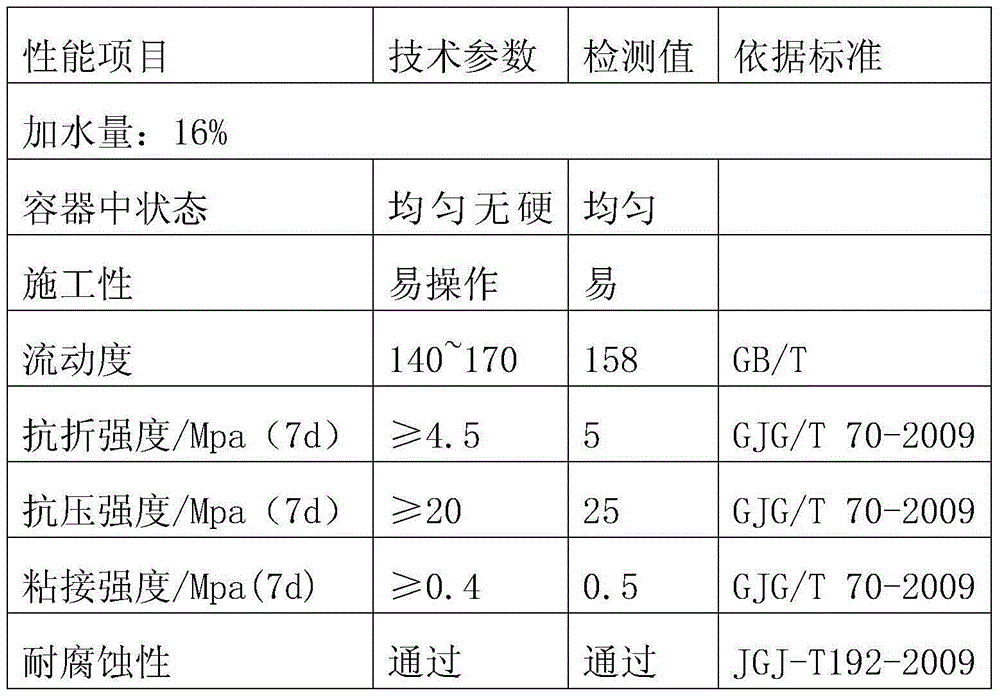

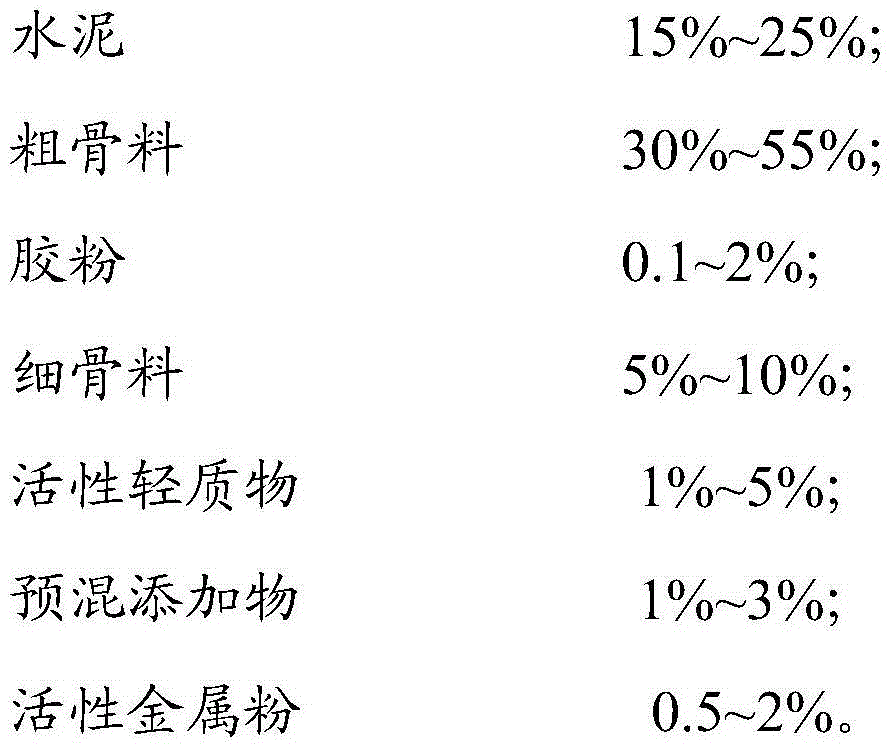

[0023] The present invention provides a polymer sprayed mortar, comprising premixed powder and water, wherein the proportion of water is 14%-17% of the premixed powder; the composition of the premixed powder includes cement based on the proportion by weight 15%~25%, coarse aggregate 30%~55%, rubber powder 0.1~2%, fine aggregate 5%~10%, active light material 1%~5%, premixed additive 1%~3% , Active metal powder 0.5-2%.

[0024] The aforementioned cement is used as a main coagulation material in the present invention to make the polymer spray mortar have better curing performance. The cement used in the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com