Multi-functional ion association type emulsion and preparation method thereof

A multi-functional and associative technology, applied in the field of multi-functional ionic associative emulsion and its preparation, can solve the problems of inability to fully satisfy the performance, inconvenient use, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

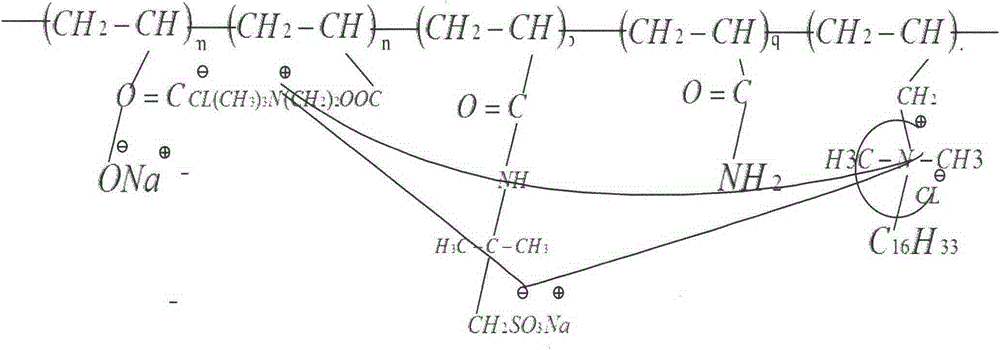

Method used

Image

Examples

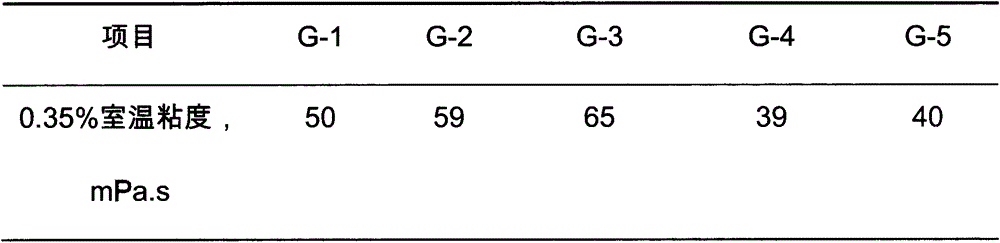

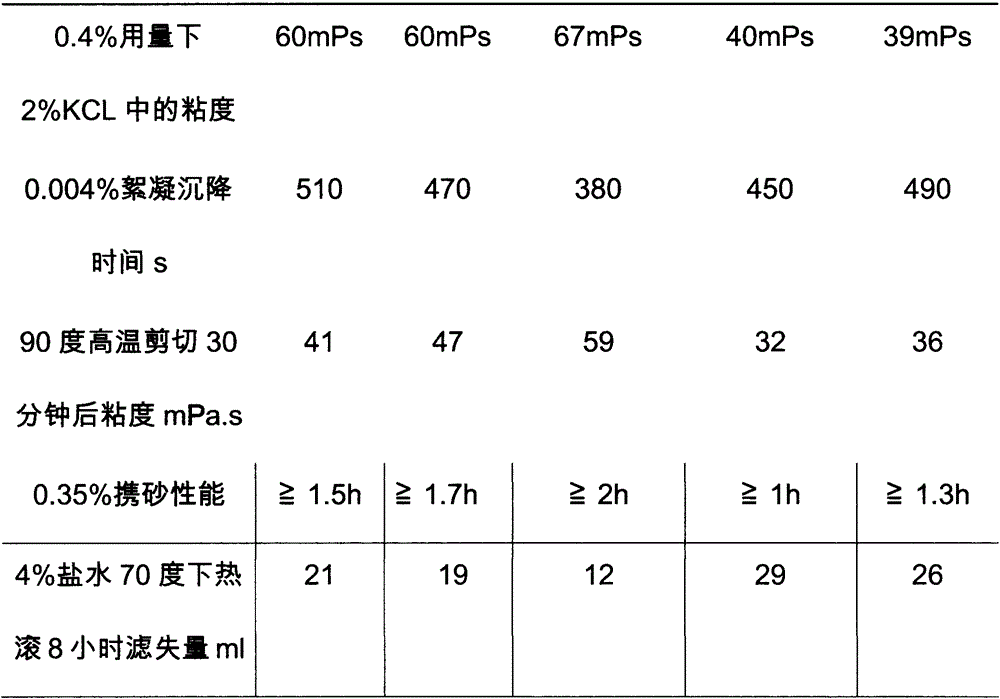

Embodiment 1

[0025] The weight ratio of each monomer DAC:AM:NaAA:C 16 DMAAC:NaAMPS=10:20:5:0.2:0.3.

[0026] Preparation of multifunctional ion association emulsion:

[0027] 1. Add 25 g of distilled water to a 100 beaker, add 10 g of DAC monomer, add 20 g of AM monomer, add 3 g of NaAA monomer, and add C 16 Add 0.2g of DMAAC monomer, add 0.3g of NaAMPS monomer, adjust the pH to 7.2 with sodium hydroxide, pass in nitrogen gas, dissolve under stirring, and adjust the temperature to 25±1°C. as the aqueous phase.

[0028] 2. Take 4g of composite nonionic emulsifier by weighing Span65 and Twee65 to make the amount 10:1, add 28g of organic solvent kerosene and stir for 40 minutes at a speed of 500 rpm to form a stable emulsion as the oil phase.

[0029] 3. Slowly add the water phase to the oil phase at a speed of 500 rpm, maintain a constant temperature environment of 45 degrees, add 0.07% ammonium persulfate and sodium sulfite under the protection of nitrogen, and stir for 4-6 hours to form...

Embodiment 2

[0031] The weight ratio of each monomer DAC:AM:NaAA:C 16 DMAAC:NaAMPS=8:21:7:0.1:0.3.

[0032] Preparation of multifunctional ion association emulsion:

[0033] 1. Add 26 g of distilled water to a 100 beaker, add 8 g of DAC monomer, add 21 g of AM monomer, add 7 g of NaAA monomer, and add C 16 Add 0.1 g of DMAAC monomer, add 0.3 g of NaAMPS monomer, adjust the pH to 7.9 with sodium hydroxide, pass in nitrogen gas, dissolve under stirring, and adjust the temperature to 25±1°C. as the aqueous phase.

[0034] 2. Take 4g composite nonionic emulsifier by weighing Span65, OP-10, wee65 to make its volume ratio 6:0.5:1, add 29g of organic solvent kerosene and stir for 40 minutes at a speed of 500 rpm to form a stable emulsion, as oily phase.

[0035] 3. Slowly add the water phase to the oil phase at a speed of 500 rpm, maintain a constant temperature environment of 45 degrees, add 0.1% ammonium persulfate and sodium sulfite under nitrogen protection, and stir for 4-6 hours to form...

Embodiment 3

[0037] The weight ratio of each monomer DAC:AM:NaAA:C 16 DMAAC:NaAMPS=12:20:5:0.01:0.2.

[0038] Preparation of multifunctional ion association emulsion:

[0039] 1. Add 26 g of distilled water to a 100 beaker, add 12 g of DAC monomer, add 20 g of AM monomer, add 5 g of NaAA monomer, and add C 16 Add 0.01 g of DMAAC monomer, add 0.2 g of NaAMPS monomer, adjust the pH to 7.0 with sodium hydroxide, pass in nitrogen gas, dissolve under stirring, and adjust the temperature to 25±1°C. as the aqueous phase.

[0040] 2. Weigh 4g of composite nonionic emulsifier by Span80 and Twee80 to make the ratio 4:1, add 28g of organic solvent kerosene and stir for 30 minutes at a speed of 500 rpm to form a stable emulsion as the oil phase.

[0041]3. Slowly add the water phase to the oil phase at a speed of 500 rpm, maintain a constant temperature environment of 47 degrees, add 0.10% ammonium persulfate and sodium sulfite, and 0.05% azobisisobutyronitrile under nitrogen protection, and stir t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com