Preparation and application methods of polyepoxysuccinic acid derivative scale inhibitor

A technology of polyepoxysuccinic acid and sodium epoxysuccinate, which is applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., and can solve environmental hazards, low efficiency of scale inhibition, use Problems such as high cost, to achieve the effect of not destroying the ecological environment, improving the linear structure, and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A. Cyclization reaction and purification of cyclization products

[0024] aAdd 16g of NaOH and 36ml of water into the three-necked flask, put the three-necked flask into a magnetic stirring water bath, fully dissolve under magnetic stirring, then add 19.6g of maleic anhydride, while the temperature of the water bath is raised to 55°C. After the water bath was heated to 55°C, the catalyst 1.2gNa was added 2 WO 4 . Finally, raise the temperature of the water bath to 70°C. After the temperature stabilizes, use a separatory funnel to evenly add 24ml of hydrogen peroxide dropwise within 35 minutes. At this point, 1:1 hydrochloric acid solution was used to adjust the pH to 6-7, and the mixed crude product was obtained after 1.5 hours of reaction.

[0025] b product purification: the mixed crude product of step a is heated with an electric heating mantle, and vacuumized simultaneously for distillation under reduced pressure. When the remaining liquid after evaporation is 1...

Embodiment 2

[0031] A. Cyclization reaction and purification of cyclization products

[0032] a Add 13g of NaOH and 35ml of water into the three-necked flask, put the three-necked flask into a magnetic stirring water bath, fully dissolve under magnetic stirring, add 18g of maleic anhydride, and raise the temperature of the water bath to 52°C. After the temperature of the water bath was raised to 52°C, the catalyst 1gNa was added 2 WO 4 . Finally, raise the temperature of the water bath to 65°C. After the temperature is stable, use a separatory funnel to evenly add 20ml of hydrogen peroxide dropwise within 30 minutes. At this time, start to adjust the pH=6-7 with 1:1 hydrochloric acid solution, and get mixed crude product after reacting for 1 hour.

[0033] b product purification: the mixed crude product of step a is heated with an electric heating mantle, and vacuumized simultaneously for distillation under reduced pressure. When the remaining liquid after evaporation is 1 / 2 of the vol...

Embodiment 3

[0039] A. Cyclization reaction and purification of cyclization products

[0040] a Add 18g of NaOH and 38ml into the three-necked flask, put the three-necked flask into a magnetic stirring water bath, fully dissolve under magnetic stirring, add 20g of maleic anhydride, and raise the temperature of the water bath to 58°C. After the temperature of the water bath was raised to 58°C, the catalyst 1.5gNa was added 2 WO 4 Finally, raise the temperature of the water bath to 75°C, and after the temperature stabilizes, use a separatory funnel to evenly add 26ml of hydrogen peroxide dropwise within 40 minutes. At this point, a 1:1 hydrochloric acid solution was used to adjust the pH to 7, and the mixed crude product was obtained after 2 hours of reaction.

[0041] b product purification: the mixed crude product of step a is heated with an electric heating mantle, and vacuumized simultaneously for distillation under reduced pressure. When the remaining liquid after evaporation is 1 / 2 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

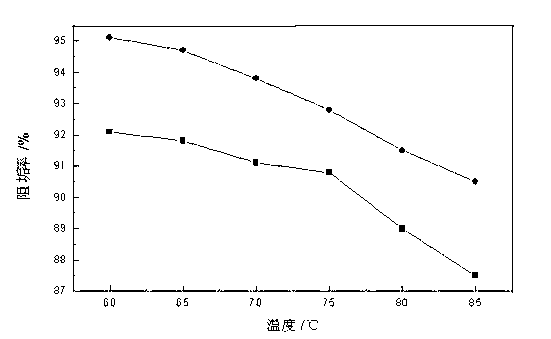

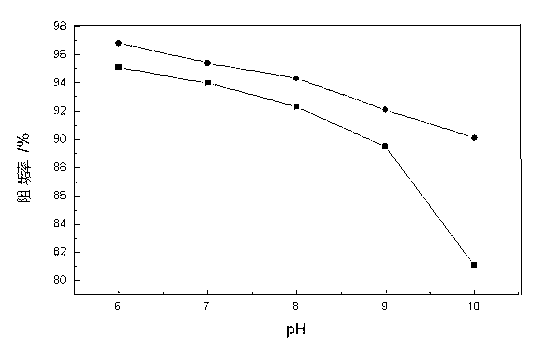

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com