Automatic circulating cooling water control device for air compressor

An automatic control device and air compressor technology, applied in pump control, machine/engine, mechanical equipment, etc., can solve problems such as unsatisfactory control methods, unit failure to work normally, waste of circulating water energy, etc., to reduce labor costs , reduce waste, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

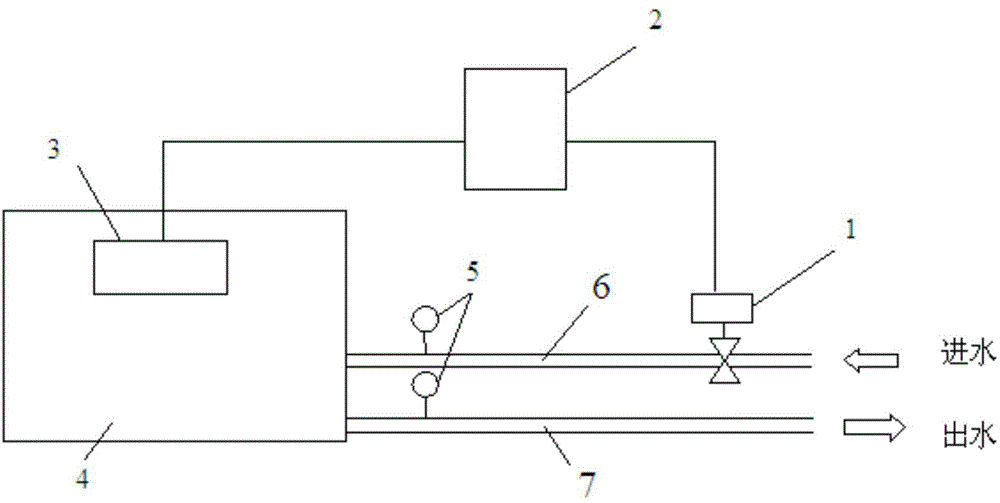

[0019] Such as figure 1 As shown, an automatic control device for circulating cooling water of an air compressor includes a water inlet pipe 6, an outlet pipe 7, an electric valve 1, an electrical control cabinet 2 and an air compressor control panel 3, and the water inlet pipe 6 and the outlet pipe 7 are respectively connected with the air compressor 4, the electric valve 1 is installed on the water inlet pipe 6, and connected with the electric control cabinet 2, and the electric control cabinet 2 is connected with the air compressor control panel 3 .

[0020] The electrical control cabinet 2 includes a control relay and a delay relay, and the control panel 3 of the air compressor is provided with a start-stop button;

[0021] The air compressor control panel 3 sends the start-stop button signal to the electric control cabinet in real time, and the electric control cabinet 2 triggers the control relay and the delay relay to control the electric valve on the water inlet pipe ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap