A bonding-free LED lamp tube and an integrated bonding-free fixing method

A technology of LED lamp tube and fixing method, which is applied in the direction of light source fixing, semiconductor devices of light-emitting elements, components of lighting devices, etc., which can solve the disadvantages of high-efficiency production, large labor and production time consumption, complex processing procedures of lamp tube covers, etc. problems, achieve fast installation and fixation, and improve assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment technical solution of the present invention is described in detail:

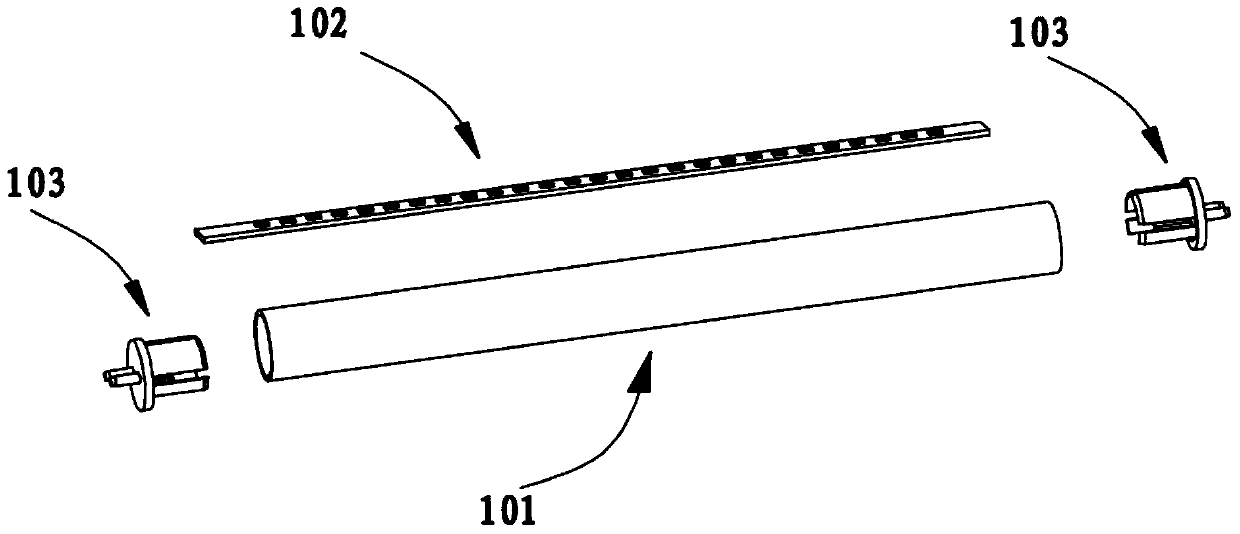

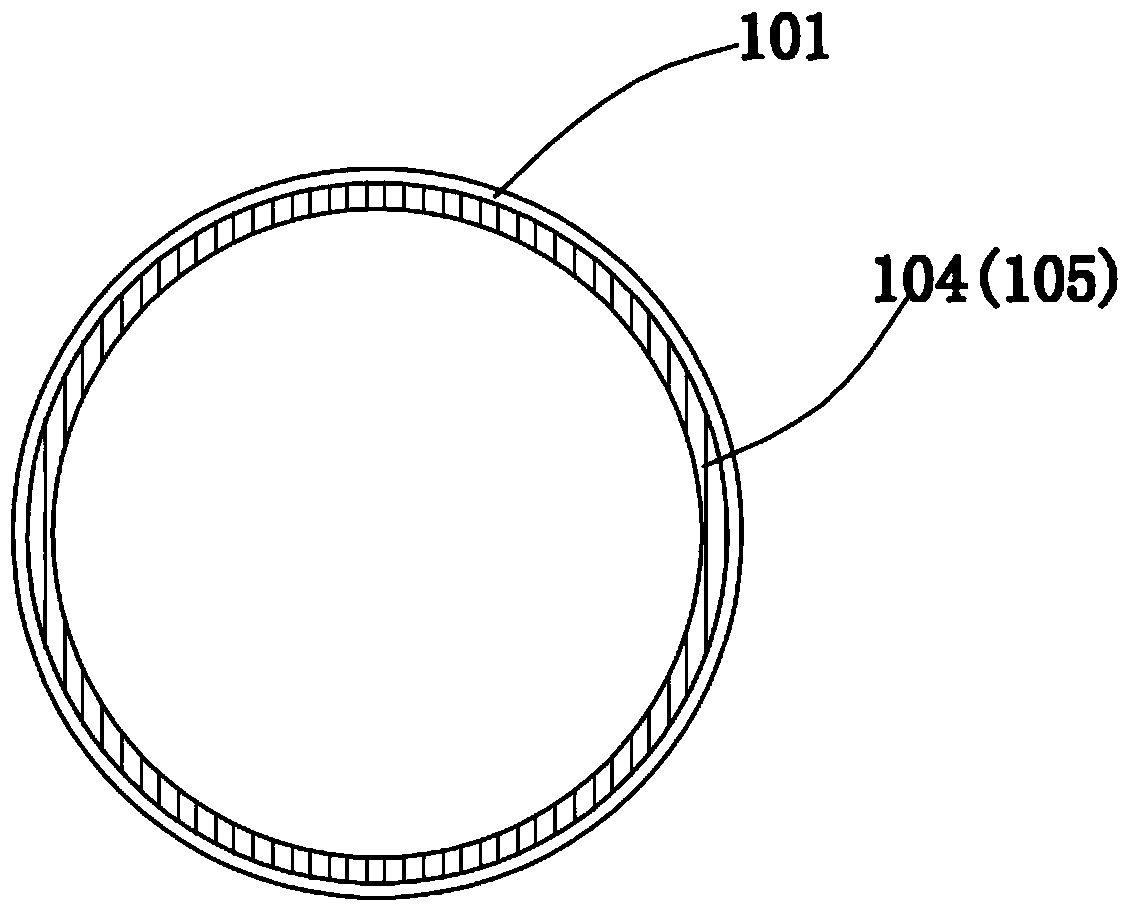

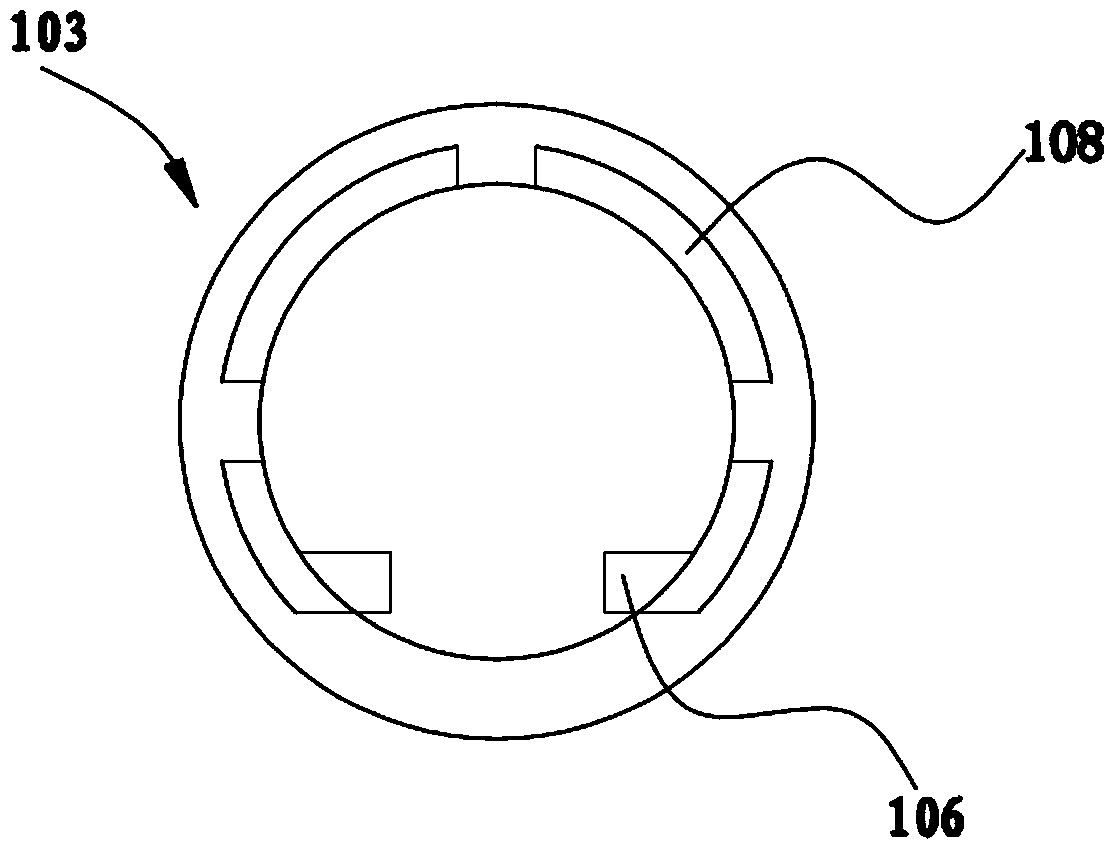

[0028] see Figure 1 to Figure 2 , as shown in the figure, the present invention provides a non-adhesive LED lamp tube, which includes a lamp cover 101, a lamp plate 102 arranged in the lamp cover 101 and a The lamp holders 103 at both ends of the lamp cover 101, wherein the inner surface of the lamp cover 101 is provided with an elastic body 104 or a flexible body 105, and the lamp holder 103 is clamped on the inner surface of the lamp cover 101, and The elastic body 104 or the flexible body 105 forms a clip connection, which can also be understood as an interference fit, or a mutual extrusion friction connection. The purpose is to insert the lamp holder 103 into the lamp cover 101. At this time, the outer wall of the lamp holder 103 and the elastic body 104 or flexible body 105 on the inner wall of the lamp cover 101 form a snap connection or It is called a mut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com