Metal pipe fitting positioning drilling edge pulling machine

A technology of metal pipe fittings and side machines, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as excessive labor, lack of equipment and fixtures, alignment, and drilling difficulties, so as to save labor and fast installation and fixation , mobile light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

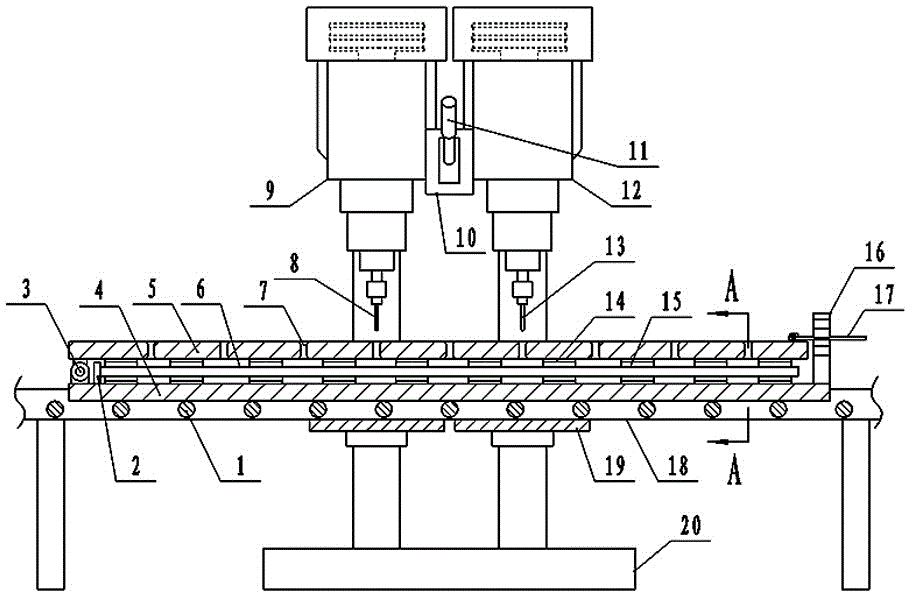

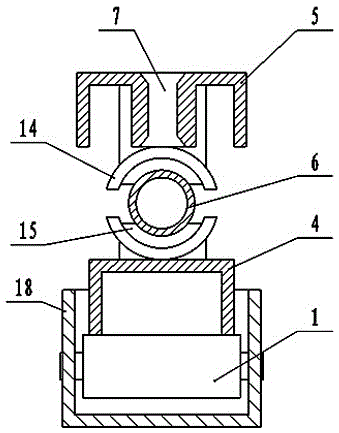

[0007] Example: such as figure 1 and figure 2 As shown, a metal pipe fitting positioning drilling edge pulling machine is formed by two fixed bench drills installed side by side, one of which is a perforating drill 9, and a drill bit 8 for punching holes on the pipe fitting is installed on it. The other is an edge-extracting drill 12, on which an edge-extracting head 13 for pulling up the edge of the metal hole is installed, and the lifting wheels 10 of the two bench drills are connected together, and a shared handle 11 is installed on the lifting wheel 10 , two bench drills are mounted on a fixed seat 20; a fixed frame 18 is fixedly installed on the lifting workbench 19 of the two bench drills, and the upper end of the fixed frame 18 is a track groove, and rollers 1 and positioning are installed in the track groove The positioning frame is composed of a bottom plate 4 and a splint 5. The bottom plate 4 is installed on the roller 1 in the track groove. One end of the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com