Submersible pump silt prevention device for river pond

A submersible pump and anti-sediment technology, which is applied to pump devices, parts of pumping devices for elastic fluids, pumps, etc., can solve the problem of increased work intensity, reduced water pumping function of submersible pumps, and inability to adjust the posture of submersible pumps and other problems to achieve the effect of increasing the service life and automatically removing sundries and aquatic plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

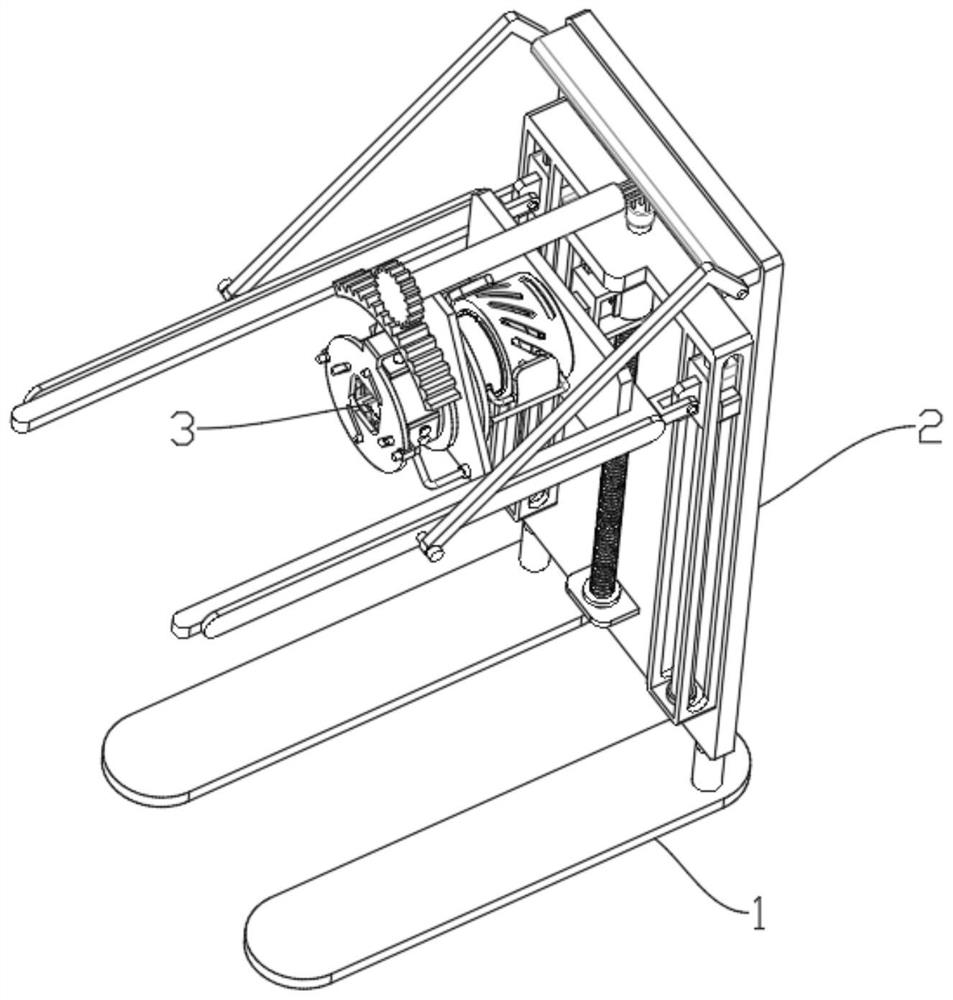

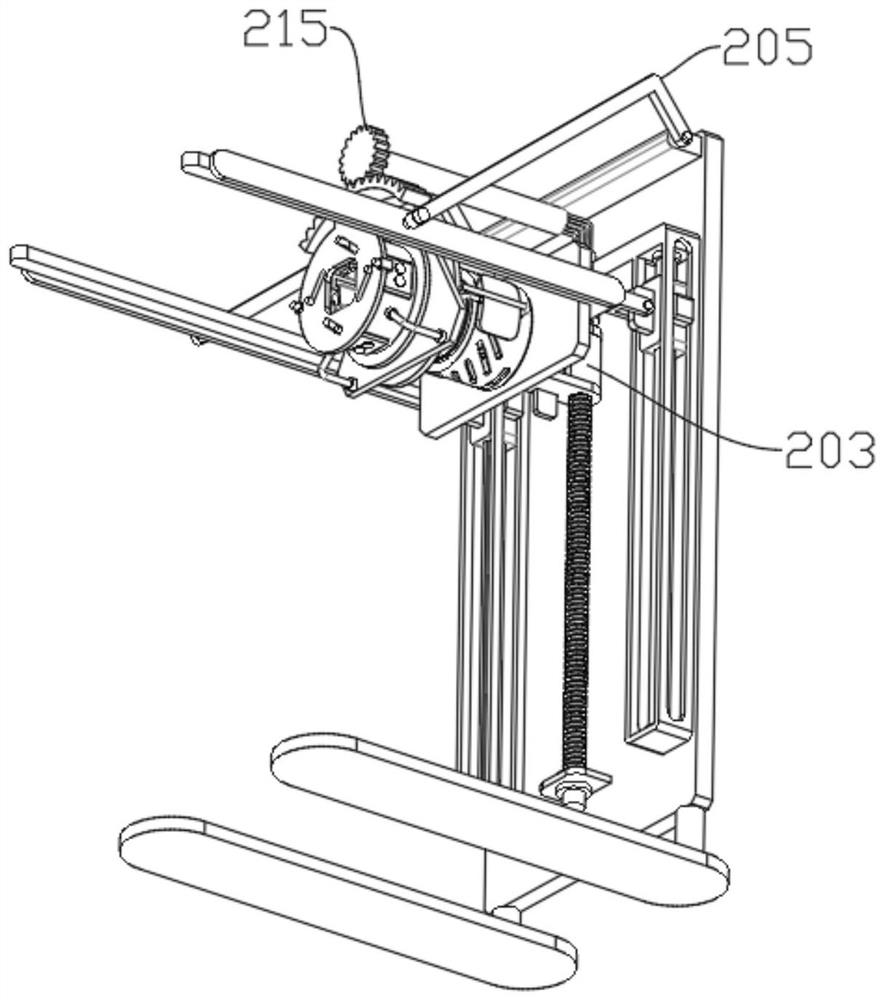

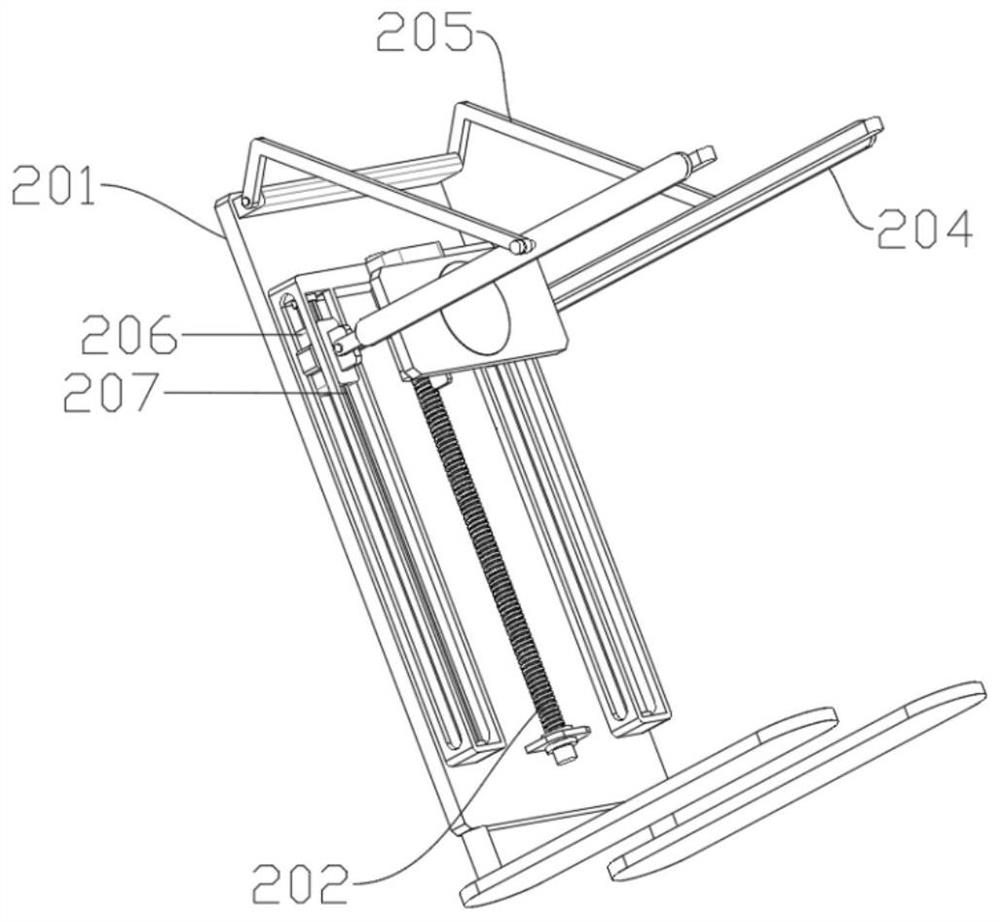

[0038] Please refer to figure 2 and image 3 and Figure 4 and Figure 5 and Image 6 and Figure 7 As shown, a submersible pump anti-sediment device for rivers and ponds includes a gravity base 1, the left end of the gravity base 1 is provided with a placement angle adjustment mechanism 2, and the left end of the placement angle adjustment mechanism 2 is provided with a docking filter mechanism 3, placed The angle adjustment mechanism 2 includes a mounting plate 201, a driving threaded rod 202, an internal threaded rotary sleeve 203, a driving frame plate 204, and a supporting curved rod 205. The middle end of the mounting plate 201 is rotationally connected with a driving threaded rod 202. There is an internal thread swivel 203, the right end of the internal thread swivel 203 is rotatably connected with a drive frame 204, the front and rear ends of the drive frame 204 are rotatably connected with a support bending rod 205, and the left end of the support bending rod 205 i...

Embodiment 2

[0041] Please refer to Figure 8 and Figure 9 and Figure 10 and Figure 11 and Figure 12 and Figure 13 and Figure 14 As shown, the docking filter mechanism 3 includes a filter cylinder 301, a high-pressure injection cylinder 302, a rubber extrusion disc 303, a protruding toggle plate 304, a slope chute disc 305, a return spring 306, and a power shaft 307. The left end surface of the drive frame plate 204 is fixedly connected with a filter cylinder 301, the inner surface of the lower end of the filter cylinder 301 is fixedly connected with a high-pressure injection cylinder 302, and the inner surface of the upper end of the high-pressure injection cylinder 302 is slidingly connected with a rubber extrusion circular plate 303, and the rubber extrusion The upper end of the pressure circular plate 303 is fixedly connected with a protruding toggle plate 304, and the middle end of the protruding toggle plate 304 is slidably connected with a power shaft 307, and the middle ...

Embodiment 3

[0044] Please refer to Figure 1 to Figure 14 As shown, a submersible pump anti-sediment device for rivers and ponds includes a gravity base 1, the left end of the gravity base 1 is provided with a placement angle adjustment mechanism 2, and the left end of the placement angle adjustment mechanism 2 is provided with a docking filter mechanism 3, placed The angle adjustment mechanism 2 includes a mounting plate 201, a driving threaded rod 202, an internal threaded rotary sleeve 203, a driving frame plate 204, and a supporting curved rod 205. The middle end of the mounting plate 201 is rotationally connected with a driving threaded rod 202. There is an internal thread swivel 203, the right end of the internal thread swivel 203 is rotatably connected with a drive frame 204, the front and rear ends of the drive frame 204 are rotatably connected with a support bending rod 205, and the left end of the support bending rod 205 is rotatably connected to the upper end of the mounting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com