Coal pulverizing system of thermal power plant and capacity expansion method thereof

A technology for a thermal power plant and a pulverizing system, which is applied to combustion methods, block/powder fuel preparation, combustion equipment, etc., can solve the problems of increased coal consumption and low investment in the pulverizing system, and reduce the cost of civil construction investment. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

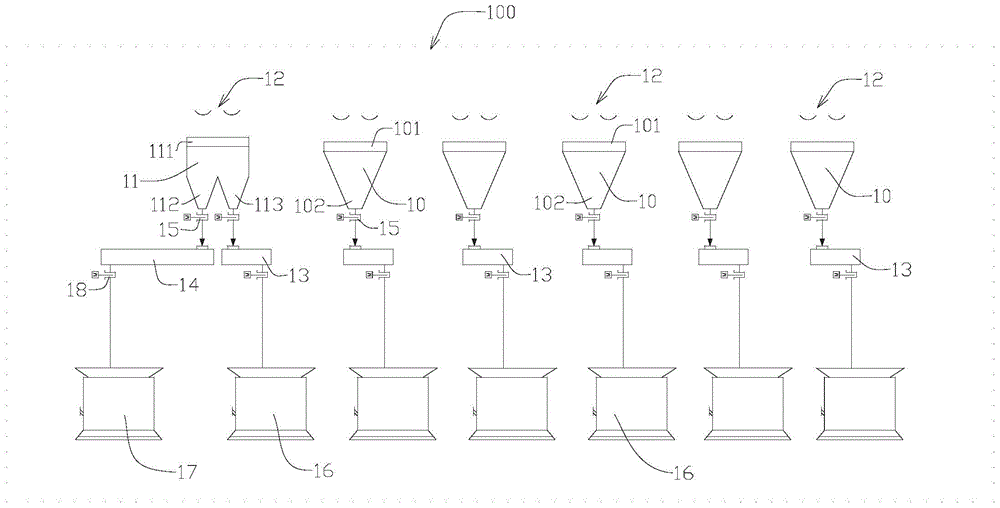

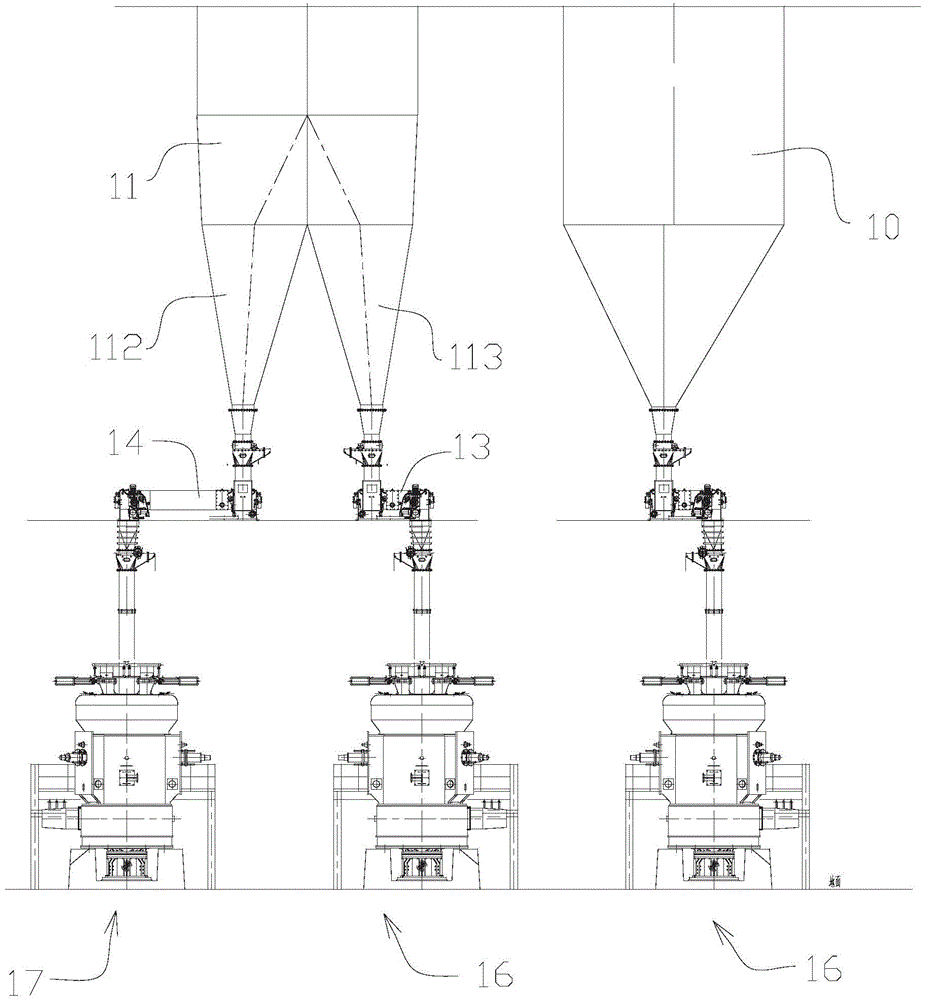

[0034] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

[0035] Explanation of terms:

[0036] Pulverizing system: In a thermal power plant, the raw coal is ground to meet the requirements of combustion fineness through a coal hopper, a coal feeder and a coal mill. The main equipment includes a coal hopper, a coal feeder and a coal mill.

[0037] Boiler design coal consumption: the coal consumption of the boiler per unit time. The combustion system design calculation is usually based on the coal consumption of the boiler under the conditions of maximum continuous output and average ambient temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com