Tooling and test method for fiber optic gyroscope vibration test

A vibration test, fiber optic gyroscope technology, applied in vibration testing, measuring devices, testing of machine/structural components, etc., can solve the problems of uncertain placement of gyroscopes, inconvenient movement of tooling, insufficient screw tightening, etc., to reduce the number of connections. Unreliable factors, the effect of ensuring consistency and traceability, improving consistency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The scheme of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. Among them, the accompanying drawings constitute a part of the application and are used to assist in explaining the technical solutions of the present invention.

[0039] Aiming at the vibration test used in the environmental test of the interferometric fiber optic gyroscope, the present invention designs an effective vibration tooling and establishes scientific operating procedures, in order to minimize the impact of environmental vibration on the gyroscope accuracy, and at the same time improve the performance of the test test. work efficiency.

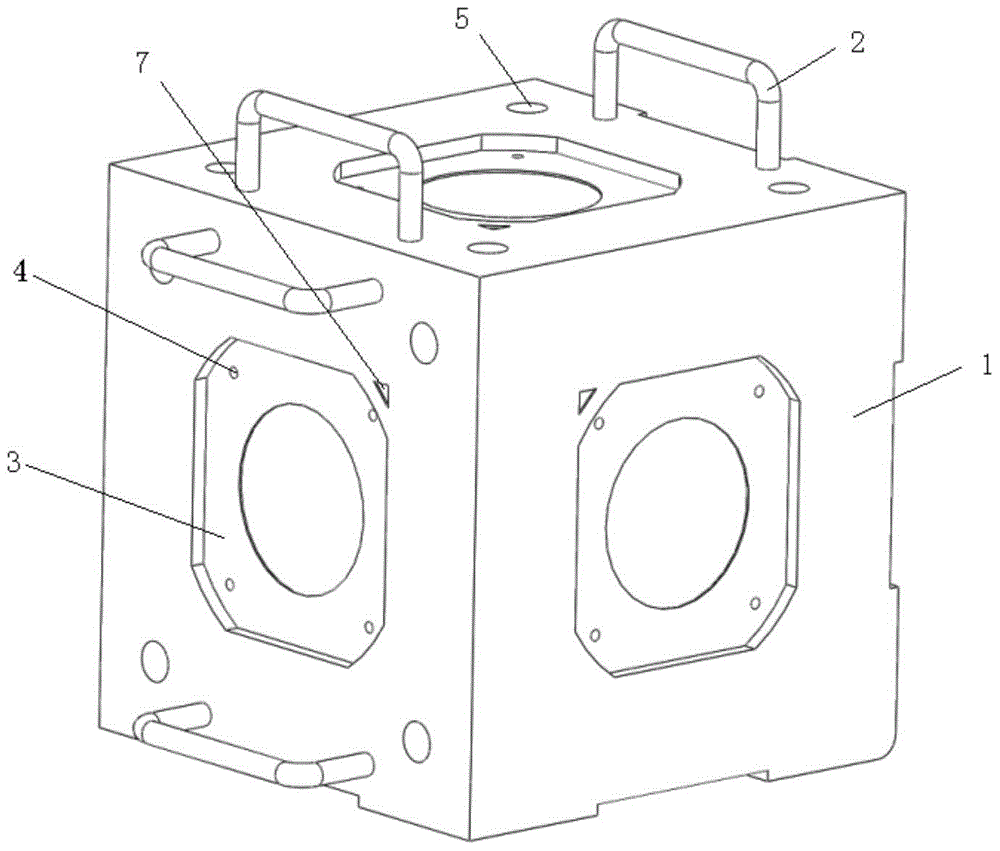

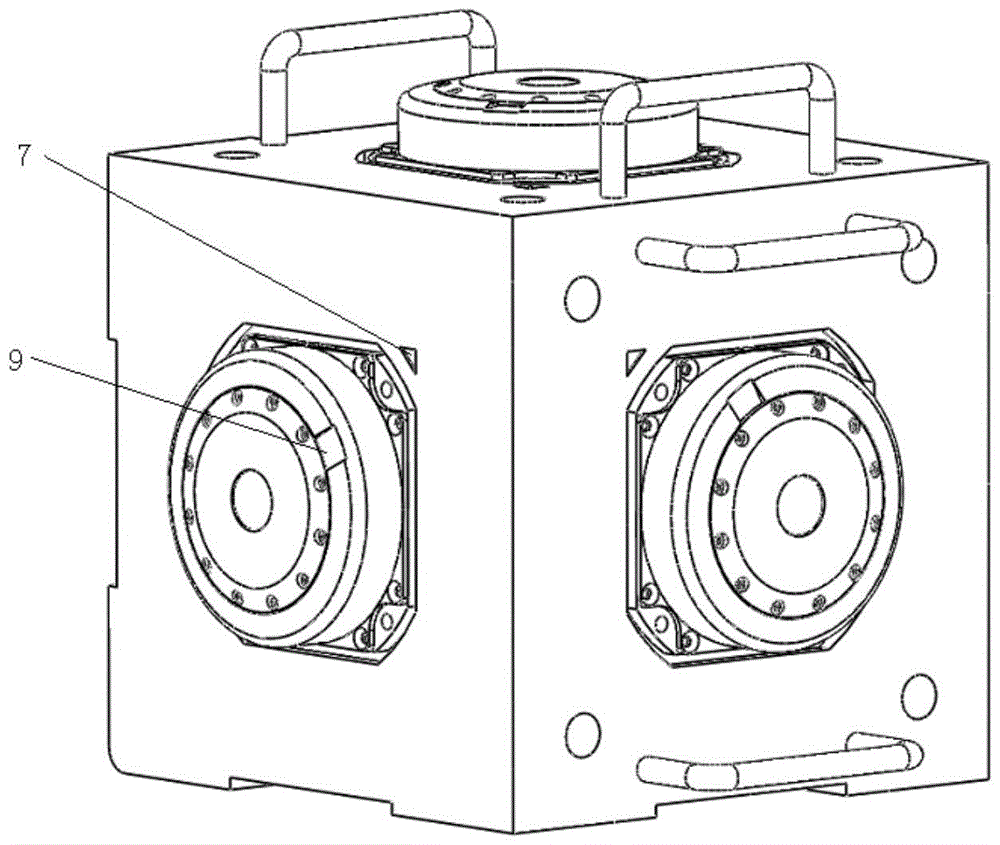

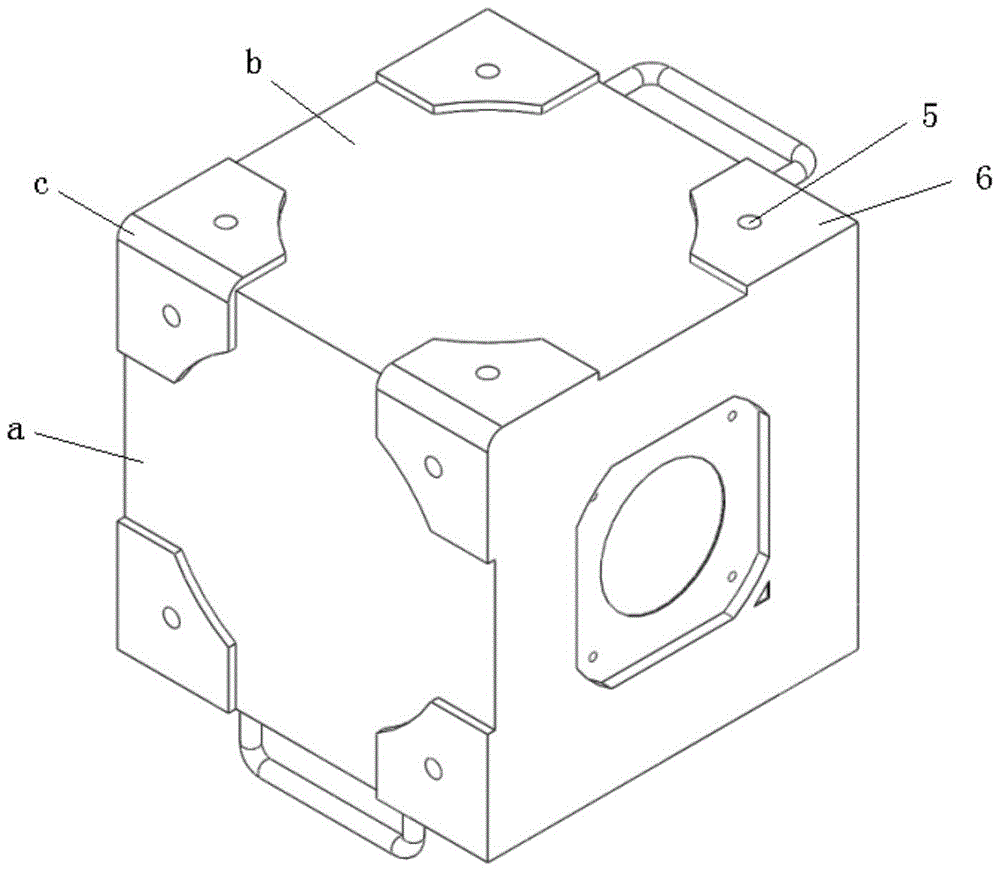

[0040] Vibration test tooling provided by the invention, such as figure 1 As shown, it includes a cube-shaped or cuboid-shaped tooling body 1, that is, a hexahedron whose two adjacent sides are perpendicular to each other. The tool body 1 has no electromagnetic shielding requirements, so alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com