Influence coefficient dynamic balance method on rotating machine with multiple plane, multiple-points and multiple revolving speed shafting

A technology of rotating machinery and influence coefficient, applied in the field of mechanical dynamic balance, can solve the problem of difficult to meet the requirements of flexible rotor dynamic balance, and achieve the effect of avoiding the seesaw phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

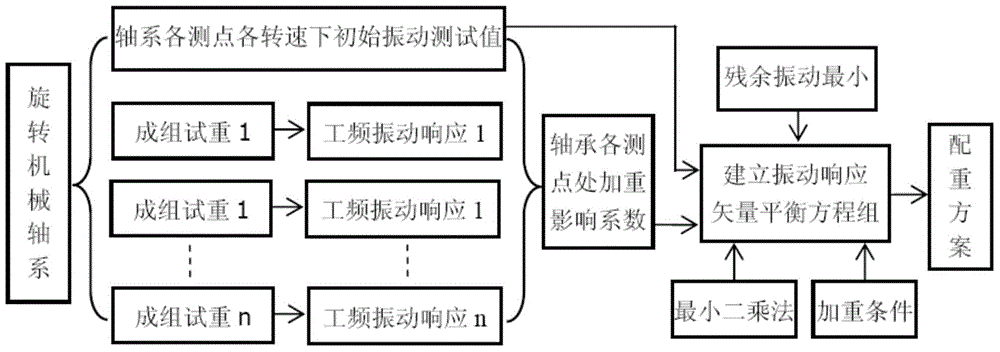

Method used

Image

Examples

Embodiment Construction

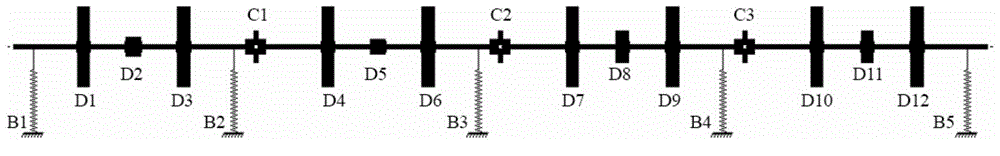

[0039] The following takes the four-span five-support multi-rotor shafting test bench as an example, the basic structure of the shafting is as attached figure 2 shown. Applying the multi-plane, multi-measuring point, multi-rotation speed shafting influence coefficient dynamic balance method of the rotating machinery proposed by the present invention, the specific implementation process of the method is further explained.

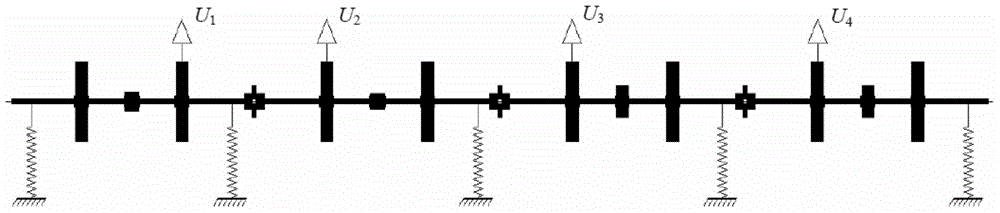

[0040]Step 1: First, on the premise of judging that the cause of the vibration of the shaft system is caused by unbalance, according to the requirements of the dynamic balance of the shaft system, combined with the structural characteristics and operating conditions of the shaft system, select the balance speed point, balance plane and number of measuring points of the shaft system . In order to avoid the "seesaw" phenomenon in the dynamic balance process of the shaft system, the test bench requires that the vibration of the shaft system before the critica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com