Passive visual system-based molten pool edge extraction method

A passive vision and edge extraction technology, applied in image data processing, instrumentation, computing, etc., can solve problems such as inability to accurately extract the edge of the molten pool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below.

[0040] A kind of melting pool edge extraction method based on passive vision system of the present invention, specifically its specific operation steps are:

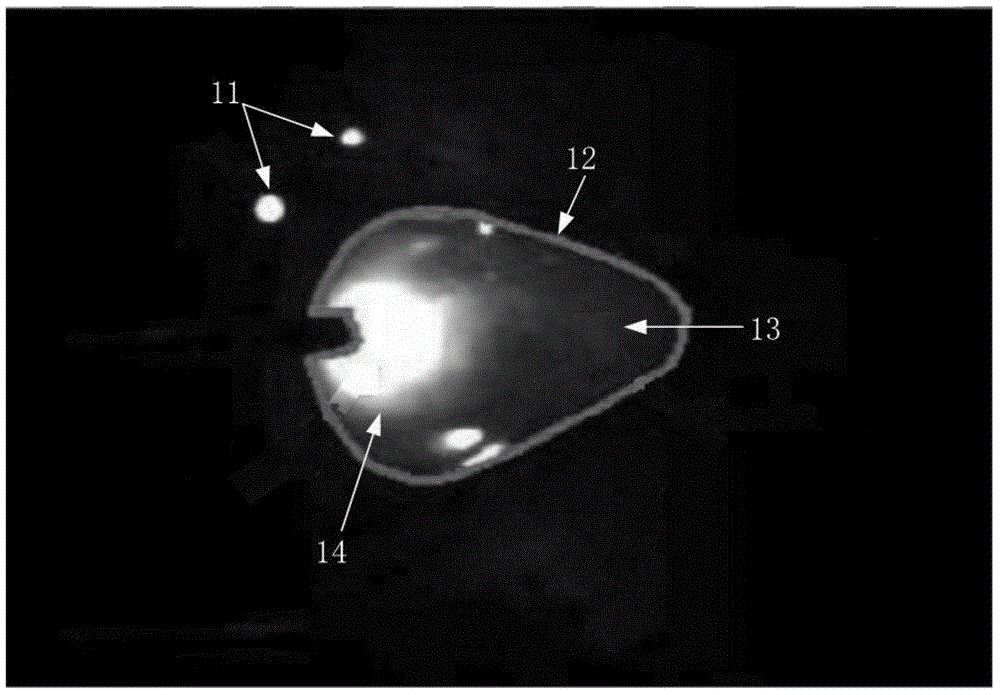

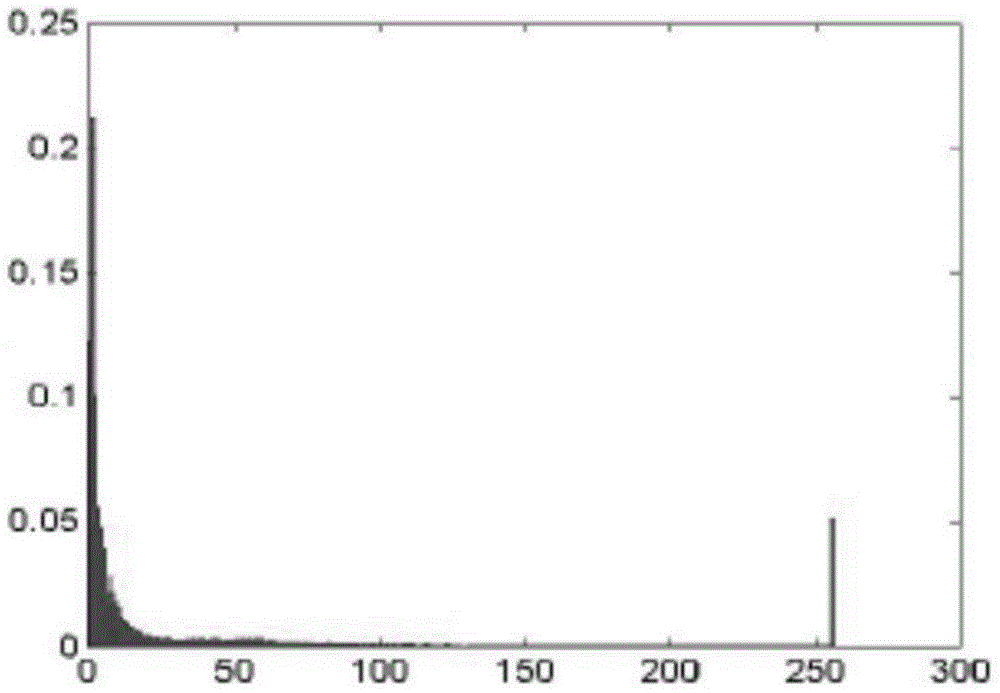

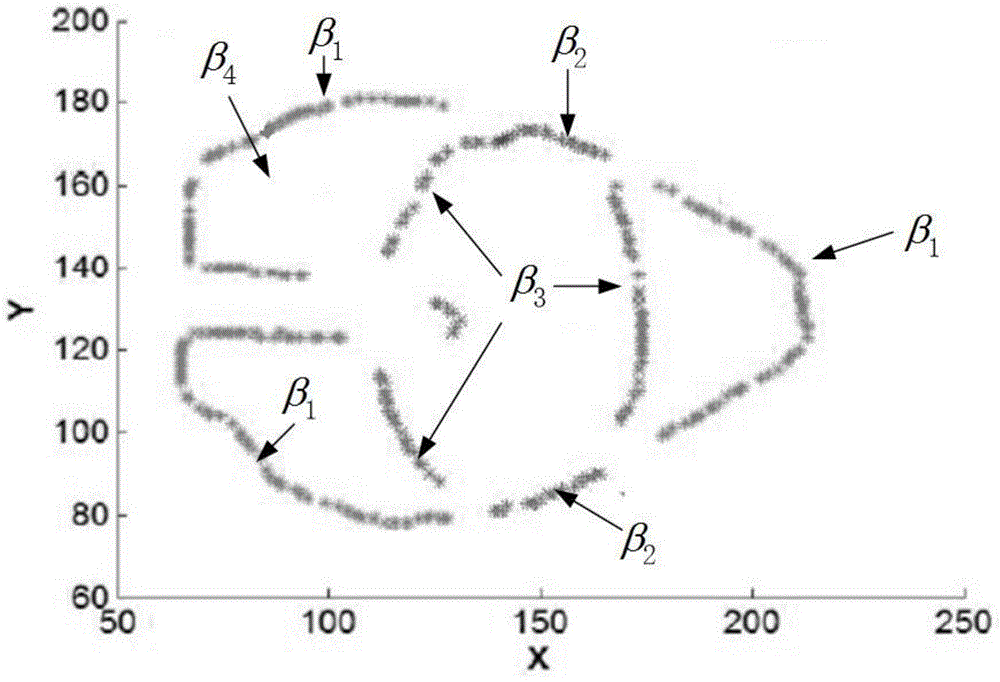

[0041] 1) Model the regions and edges of the melt pool image separately. When modeling image regions, see figure 1 , figure 2 , where 11 is solder splash, 12 is edge of molten pool, 13 is molten pool, and 14 is arc light. Divide the image region into interior regions p in (x) and the outer region p out (x), combined with its grayscale histogram features, to model the inner and outer regions as a Gaussian mixture model:

[0042] p ( x ) = Σ i = 1 N π i ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com