Circuit fault setting equipment

A circuit fault and equipment technology is applied in the field of circuit fault setting equipment, which can solve the problems of easily generating potential safety hazards, failing to achieve expected results, increasing the consumption of consumables, etc., to improve teaching effect and efficiency, easy setting and operation, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

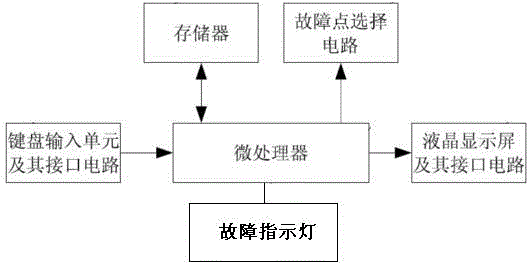

[0015] Such as figure 1 As shown, the circuit fault setting device has a microprocessor, buttons connected to the microprocessor, liquid crystal display and its drive circuit, memory, fault point selection circuit and fault indicator light; the fault point selection circuit is installed in the fault box.

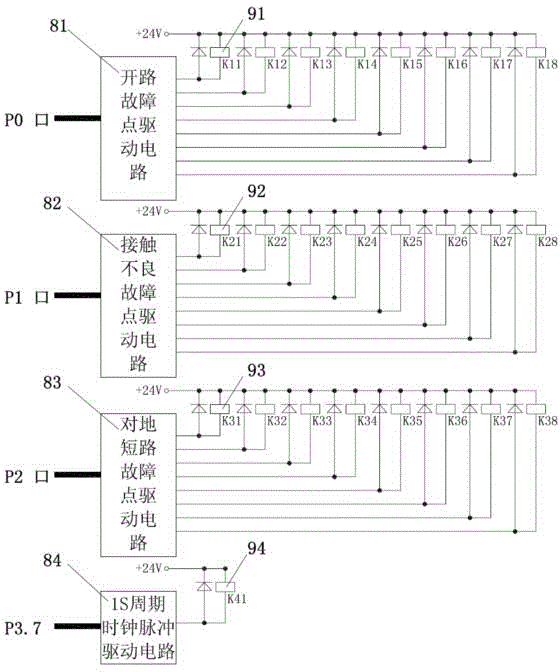

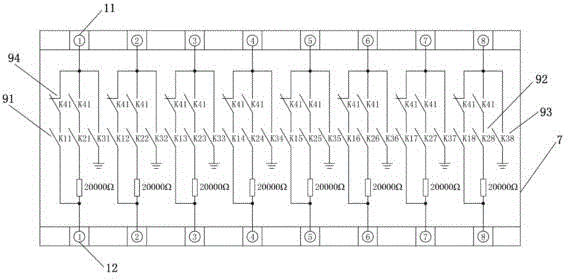

[0016] Such as figure 2 As shown, the fault point selection circuit includes a fault point drive circuit 81 that can be set on and off and a normally open fault point relay group 91 (K11, K12, K13...) corresponding to the fault point one by one, and the fault point of poor contact can be set. The fault point drive circuit 82 and the normally open fault point relay group 92 (K21, K22, K23...) corresponding to the fault point one by one (K21, K22, K23...), the fault point drive circuit 83 which is short-circuited to the ground and the one-to-one corresponding fault point Short circuit to ground normally open fault point relay group 93 (K31, K32, K33...), 1S clock cycle pulse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com