Insulated fireproof mineral cable

A mineral insulated and fireproof cable technology, applied in the direction of insulated cables, insulated conductors, cables, etc., can solve the problems of secondary disasters, ineffective isolation of air, easy release of harmful gases and smoke, etc., to achieve high safety, prevent combustion, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The core of the present invention is to provide a mineral insulated fireproof cable, which will not release harmful gas and smoke when burning, will not cause secondary disasters, and can hinder the supply of oxygen and the flow of combustible gas to prevent the cable from burning. Burn further.

[0021] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

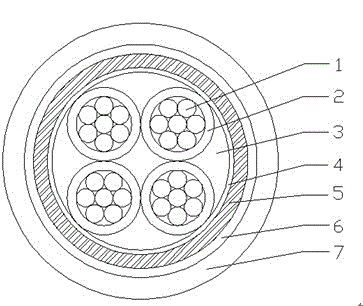

[0022] Referring to Figure 1, figure 1 A schematic cross-sectional view of a specific embodiment of the mineral insulated fireproof cable provided by the present invention.

[0023] Such as figure 1 As shown, a mineral insulated fireproof cable includes a cable inner core and a cable outer layer wrapped outside the cable inner core, and an inorganic mineral filler 3 is filled between the cable inner core and the cable outer layer; the cable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com