Permanent magnet contactor operating mechanism with trip safety device

A technology of safety device and operating mechanism, applied in electromagnetic relays, electromagnetic relay details, relays, etc., to achieve the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

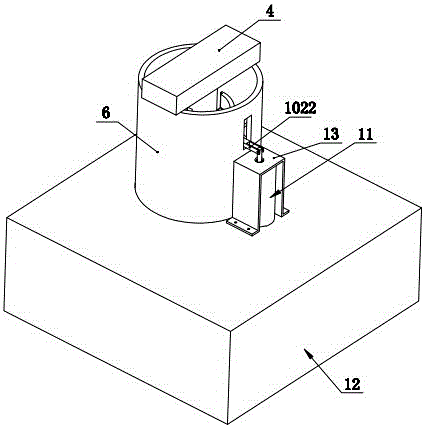

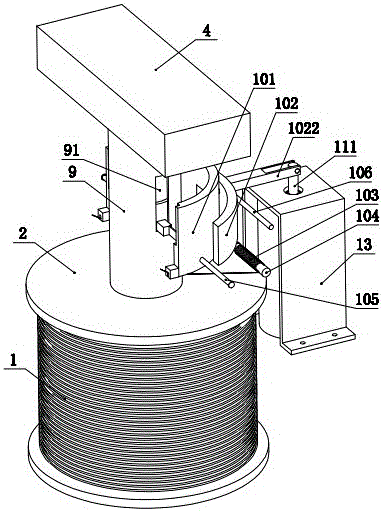

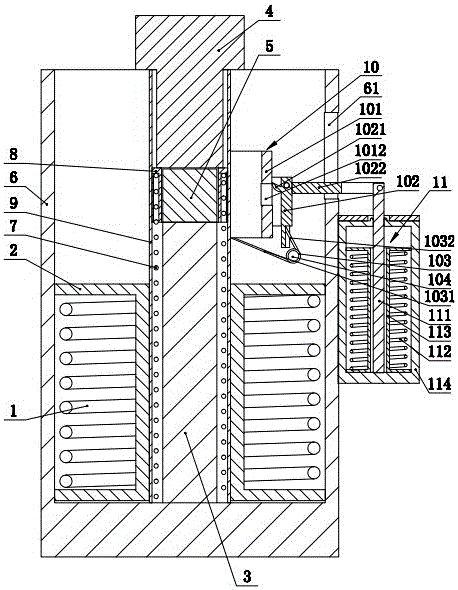

[0016] Such as figure 1 , 2 , 3, 4, 5, and 6 show a permanent magnet contactor operating mechanism with a trip safety device, including a coil 1, a coil frame 2, a static iron core 3, a moving iron core 4, and a permanent magnet 5. The yoke 6, the reaction force spring 7, the reaction force spring pressure sleeve 8, and the reaction force spring cover 9, the yoke 6 is a U-shaped structure, and the coil 1 is wound on the coil frame 2 and correspondingly located On the inner bottom surface of the U-shaped magnetic yoke 6, the static iron core 3 is penetrated in the coil frame 2, and the axial lower end of the static iron core 3 is connected with the inner bottom surface of the U-shaped magnetic yoke 6, and the described static iron core 3 The permanent magnet 5 is fixed on the axially upper end surface of the static iron core 2, and the outer coaxial sleeve of the permanent magnet 5 is provided with a reaction force spring pressure sleeve 8, and the described reaction force spr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap