Set making method capable of prolonging service life cycle of power battery pack

A technology of power battery packs and series battery packs, which is applied in the direction of secondary batteries, secondary battery repair/maintenance, circuits, etc., and can solve the problems of short battery life, inability to accurately select batteries with similar performance, and single grouping methods. To achieve the effect of improving the cycle life, increasing the service life and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

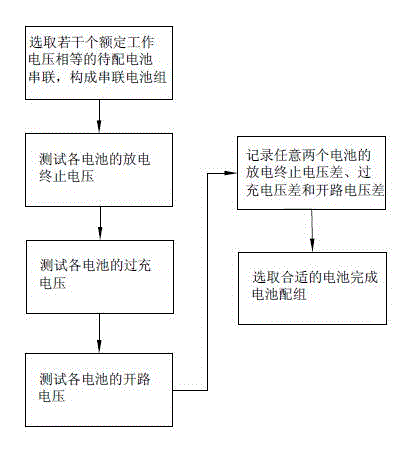

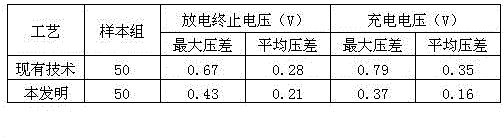

[0027] Embodiment 1: a method for improving the cycle life of a power battery pack, the flow chart of which is as follows: figure 1 shown, including the following steps:

[0028] Step 1, select 20 batteries to be distributed with equal rated working voltages in series to form a series battery pack;

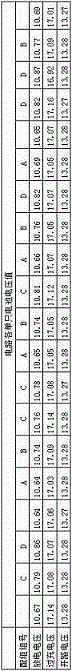

[0029] In step 2, the battery packs are connected in series to perform a discharge operation. After discharge, the voltage of a single battery drops. After the average voltage of several batteries reaches the specified first voltage of 10.7V, the discharge operation is terminated, and the voltage value of each battery at this time is recorded;

[0030] Step 3: Carry out constant voltage overcharge operation of the series connected battery pack. After the charging time of 12 hours has passed, the charging will be terminated. After the series connected battery pack has been allowed to stand for a period of 2 hours, the overcharge operation will be performed again. After the overchar...

Embodiment 2

[0037]Example 2, a method for improving the cycle life of a power battery pack, the principle and implementation method are basically the same as those in Example 1, the difference is that between step 5 and step 6, step 5a is also included, connecting the batteries in series. The group is placed in an environment where the temperature is greater than 50 °C, and it is allowed to stand for a period of time T4, and the voltage value of each battery at this time is recorded, and the difference between the voltage values of each battery is recorded as ⊿V4; the step 6 constitutes The requirements of the battery pack also include that the maximum ⊿V4 between the individual batteries in the battery pack is within the specified range; place the series battery pack in an environment where the temperature is lower than 0 °C, and let it stand for a period of time T5, and record each battery pack. The voltage value of the battery at this time, and the difference between the voltage value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com