Method for producing flavored pickled peppers by low-salt pure lactic acid fermentation

A technology of lactic acid inoculation fermentation and pure lactic acid, which is applied in the field of food engineering, can solve problems such as difficult standardization, large-scale, industrial application, poor nutritional and hygienic quality, and unfavorable human health, so as to maintain micro-ecology in the body, pure flavor quality, The effect of good appearance and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

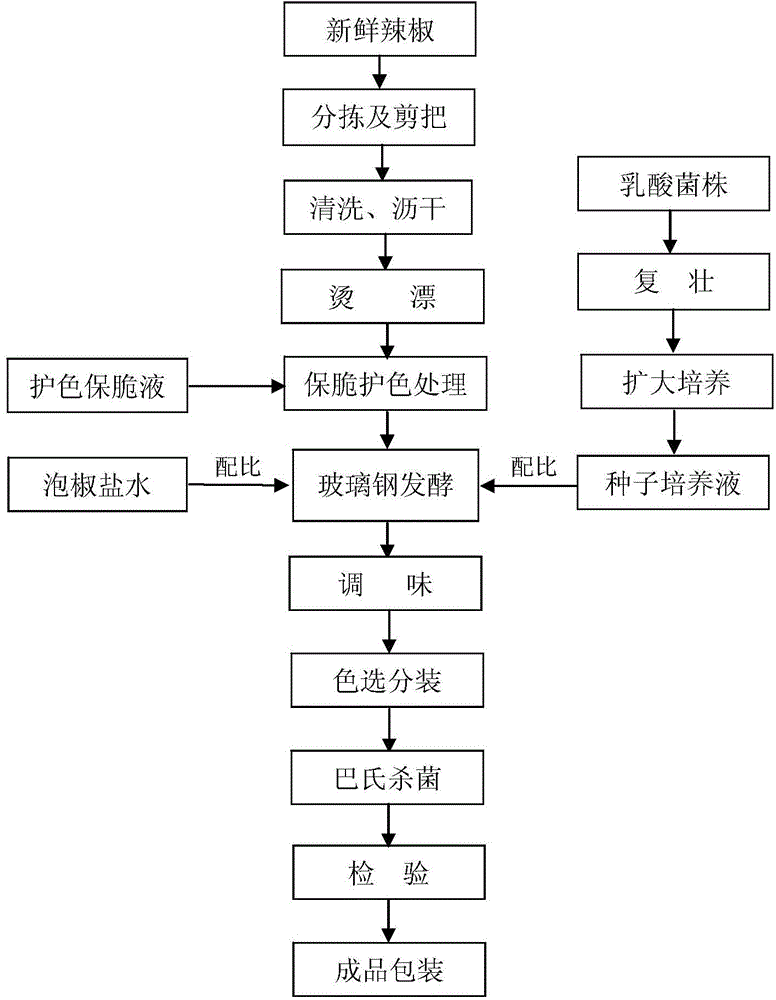

Image

Examples

Embodiment 1

[0037] The percentages involved in the present invention are mass ratios unless otherwise specified, and the water used to prepare the liquid is purified water after sterilization treatment.

[0038] (1) Raw material pretreatment: The present invention uses fresh millet hot pepper or jalapeno pepper (harvested no more than 72h) as raw material, after sorting (removing stalks and debris), cutting handles, cleaning and draining, it is color-protected and crisp deal with.

[0039] (2) Color protection and crispness: The present invention adopts the method of "low temperature blanching + color protection and crispness protection liquid" to realize the color protection and crispness of raw materials, specifically:

[0040] ① The cleaned and drained fresh peppers are blanched in purified hot water with a pH of 4.2 and a temperature of 55°C for 30 minutes and then put into the glass fiber reinforced plastic fermentation tank to prevent the peppers from browning and remove some bacteria.

[0...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap