Large-cavity segmentation ball type ultra-high pressure equipment

An ultra-high pressure, large cavity technology, applied in the application of ultra-high pressure processes, presses, methods of chemically changing substances by using atmospheric pressure, etc. Complex assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific content and implementation of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

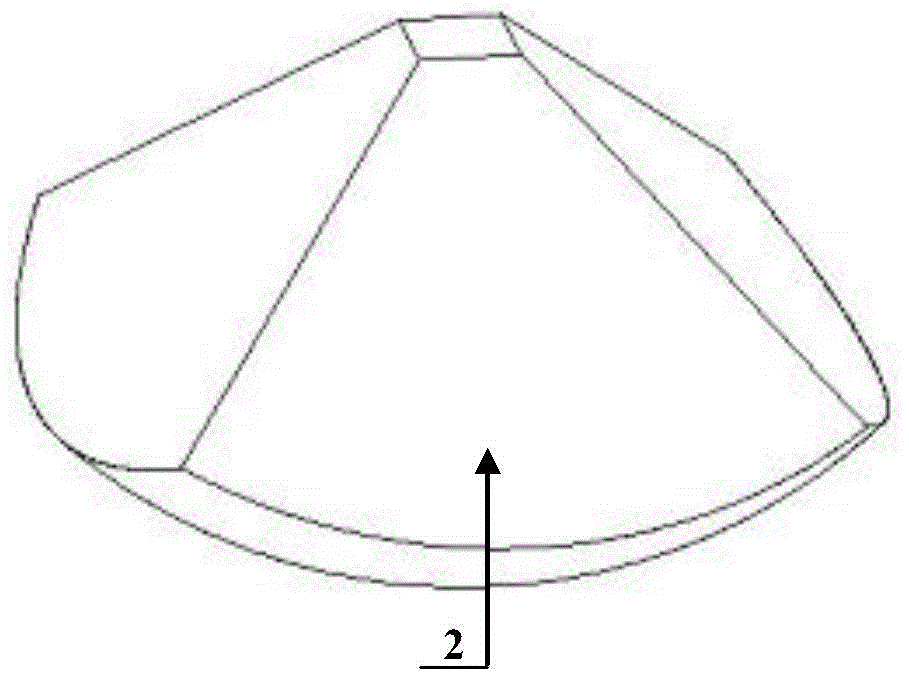

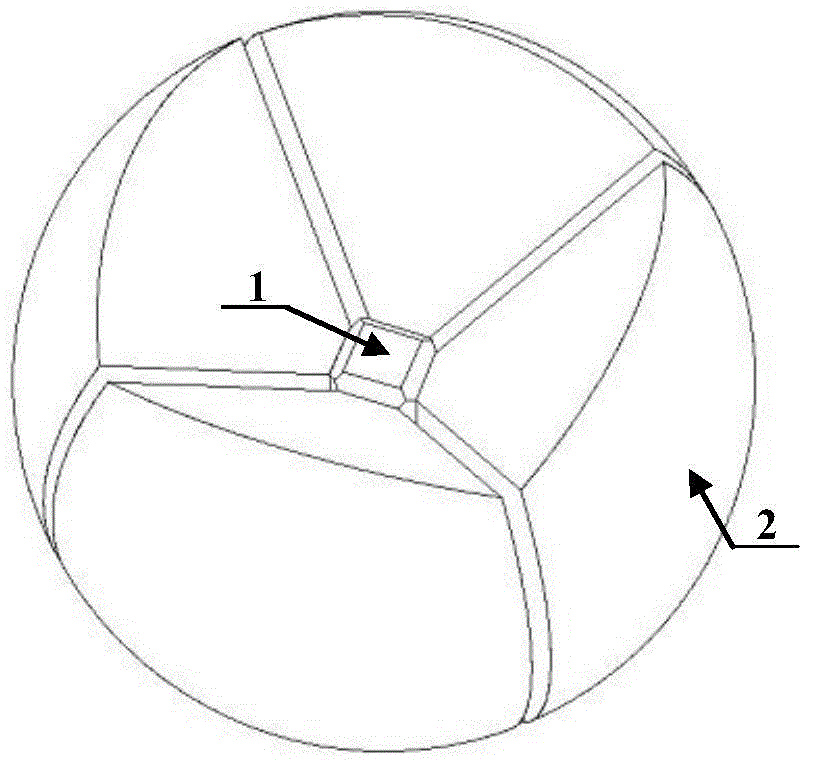

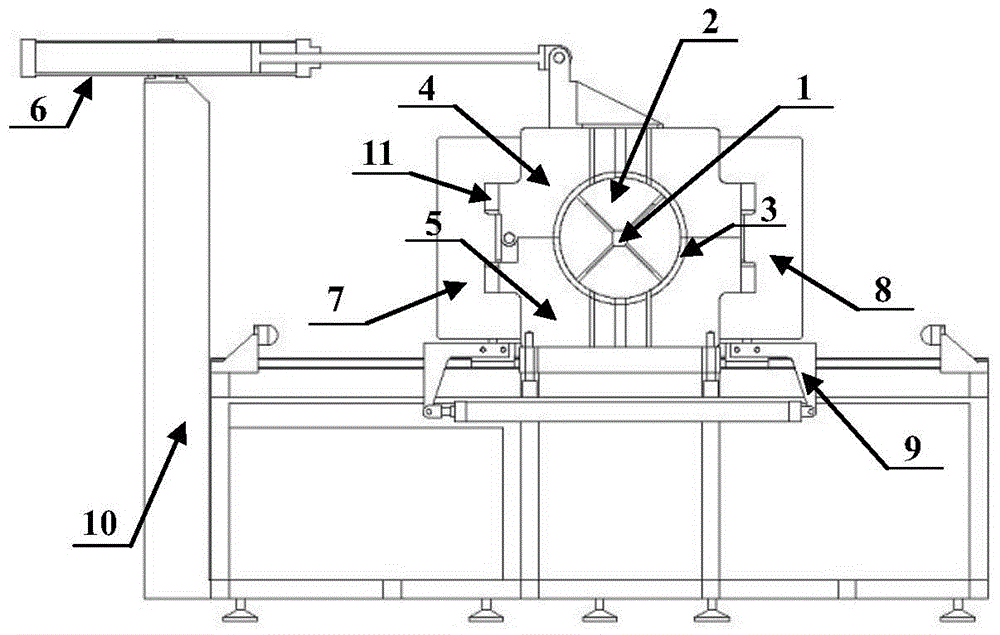

[0036] The large-cavity segmented ball type ultra-high pressure equipment of the present invention is mainly composed of an anvil, a high-pressure tank, a sheath and a frame 10 . The anvil is composed of six primary anvils with quadrangular anvil surfaces, the bottom surface of which is a spherical surface and is located inside the high-pressure tank; The position of the upper hemisphere high-pressure tank 4 is controlled by the hydraulic arm 6, and the lower hemisphere high-pressure tank 5 is fixed by bolts and frame 10, both of which are located inside the sheath; the sheath is composed of a left sheath 7 and a right sheath 8 Its axial position is fixed by the bolt and the frame 10, and its radial position is controlled by the slide rail 9; the high-pressure tank and the sheath are fixed through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com