Characteristic parameter identification method of lateral distribution of strip steel thickness on the basis of mechanism

A technology of lateral distribution and identification method, applied in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problems of inability to describe strip edge thinning, high polynomial degree, and improve the quality and parameters of cross-section and plate shape. Few, high precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

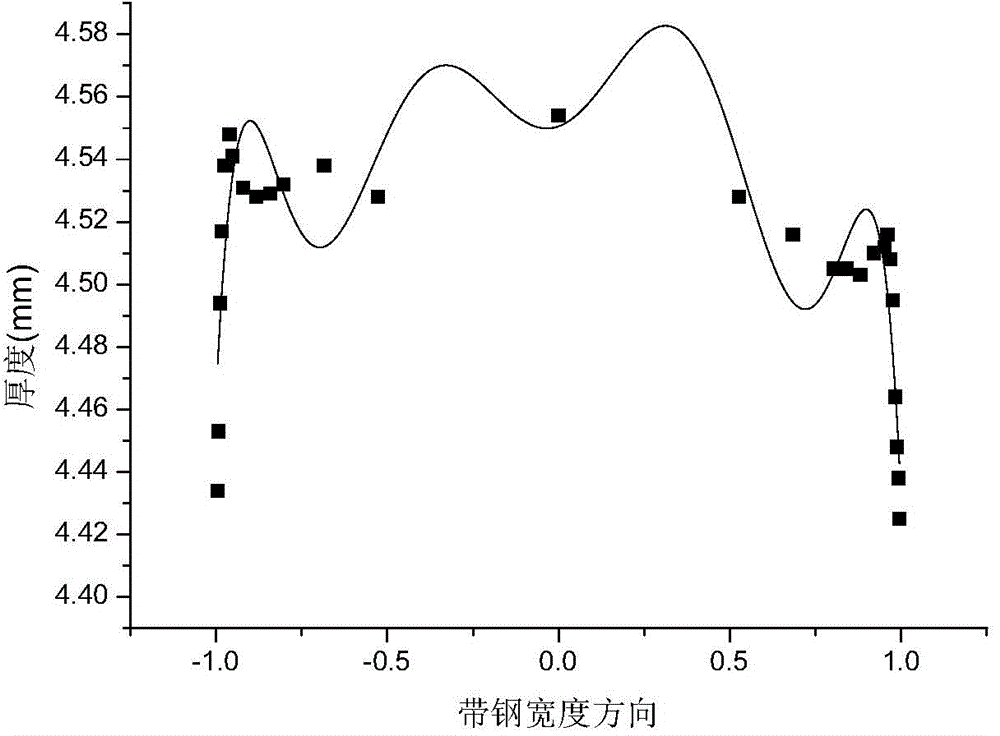

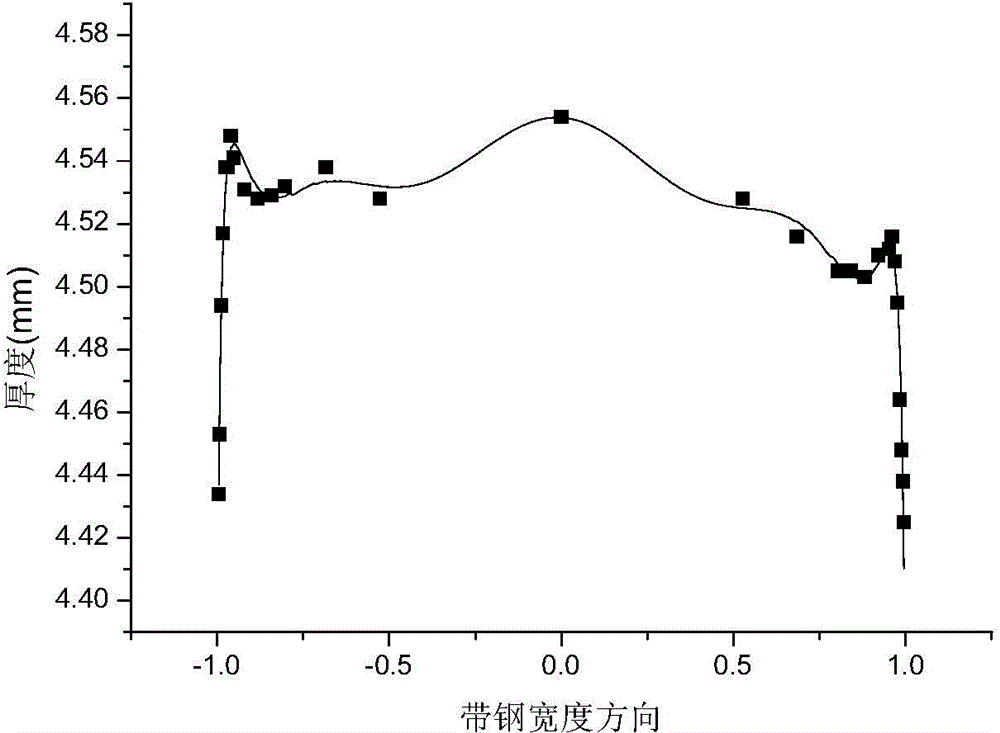

Embodiment 1

[0026] The strip width is 1268mm, and the abscissa of the measuring point and the corresponding thickness are shown in Table 1. Specific steps are as follows:

[0027] Table 1 Measured data of strip thickness lateral distribution

[0028] i

1

2

3

4

5

6

7

8

9

10

x

3

5

7

10

15

20

25

30

50

75

h(mm)

4.434

4.453

4.494

4.517

4.538

4.538

4.548

4.541

4.531

4.528

i

11

12

13

14

15

16

17

18

19

20

x

100

125

200

300

634

968

1068

1143

1158

1193

h(mm)

4.529

4.532

4.538

4.528

4.554

4.528

4.516

4.505

4.505

4.503

i

21

22

23

24

25

26

27

28

29

x

1218

1238

1243

1248

1253

1258

1261

1263

1265

h(mm)

4.51

4.512 ...

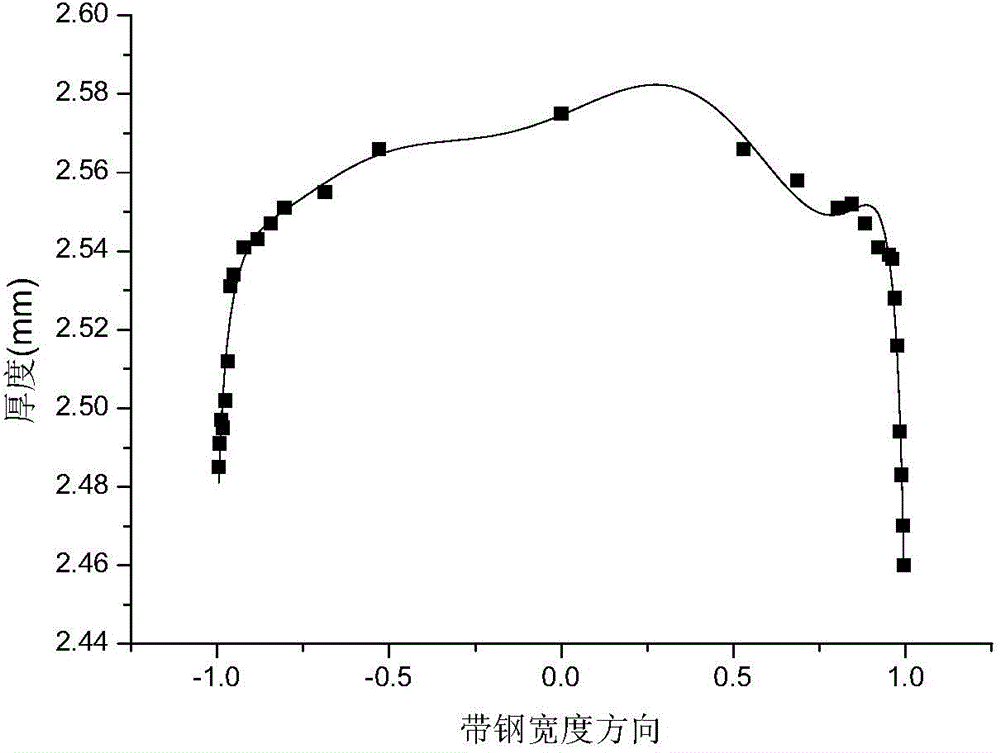

Embodiment 2

[0042] The width of the steel strip is 1276mm, and the abscissa of the measuring point and the corresponding thickness are shown in Table 2. Specific steps are as follows:

[0043] Table 2 Measured data of strip thickness lateral distribution

[0044] i

1

2

3

4

5

6

7

8

9

10

x

3

5

7

10

15

20

25

30

50

75

h(mm)

2.485

2.491

2.497

2.495

2.502

2.512

2.531

2.534

2.541

2.543

i

11

12

13

14

15

16

17

18

19

20

x

100

125

200

300

638

976

1076

1151

1176

1201

h(mm)

2.547

2.551

2.555

2.566

2.575

2.566

2.558

2.551

2.552

2.547

i

21

22

23

24

25

26

27

28

29

x

1226

1246

1251

1256

1261

1266

1269

1271

1273

h(mm)

2.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com